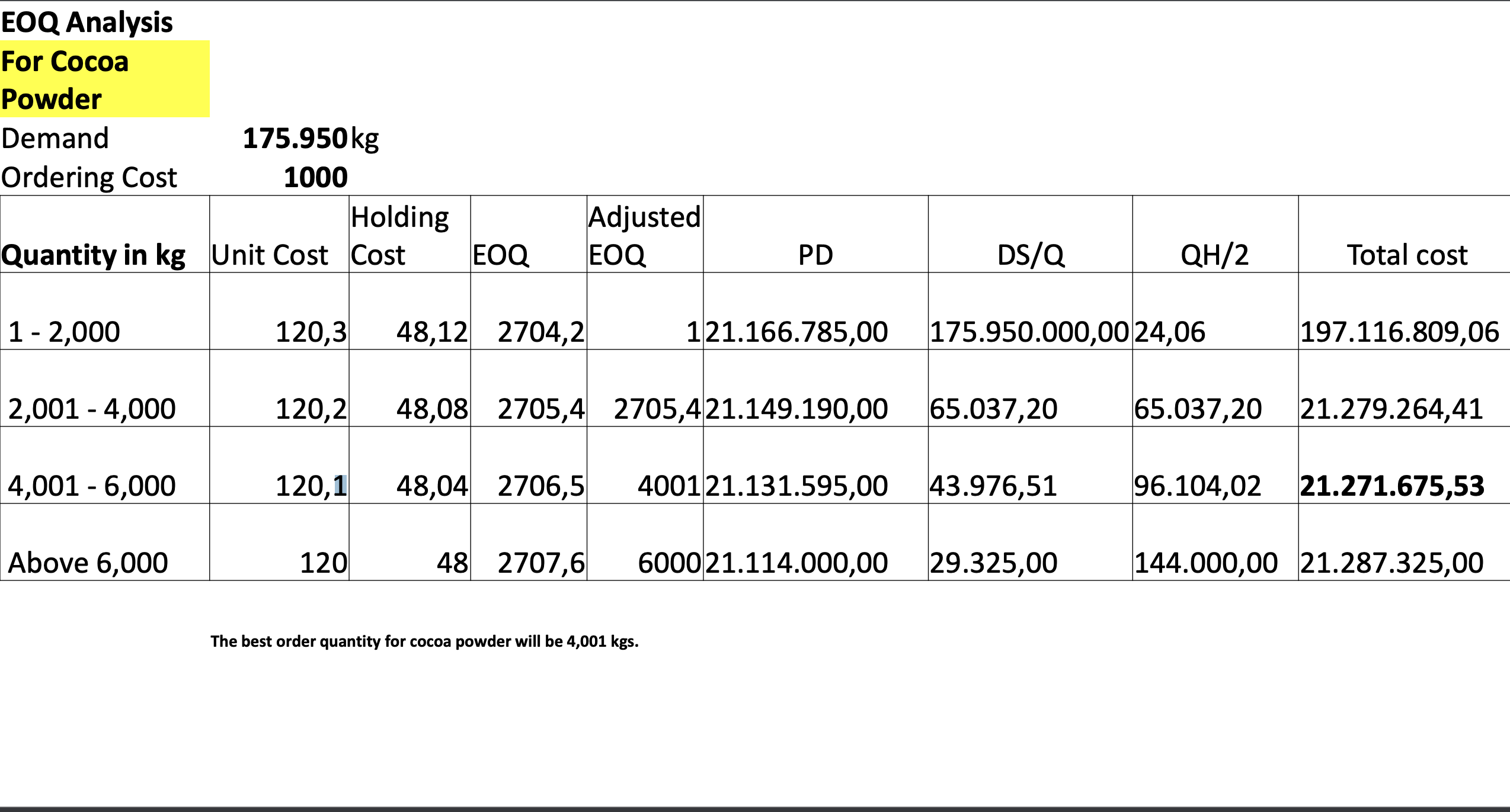

Question: Please help with this operations case study! The best order quantity for cocoa powder will be 4,001 kgs. EOQ Analysis For Cocoa Powder Demand 175,950Kg

Please help with this operations case study!

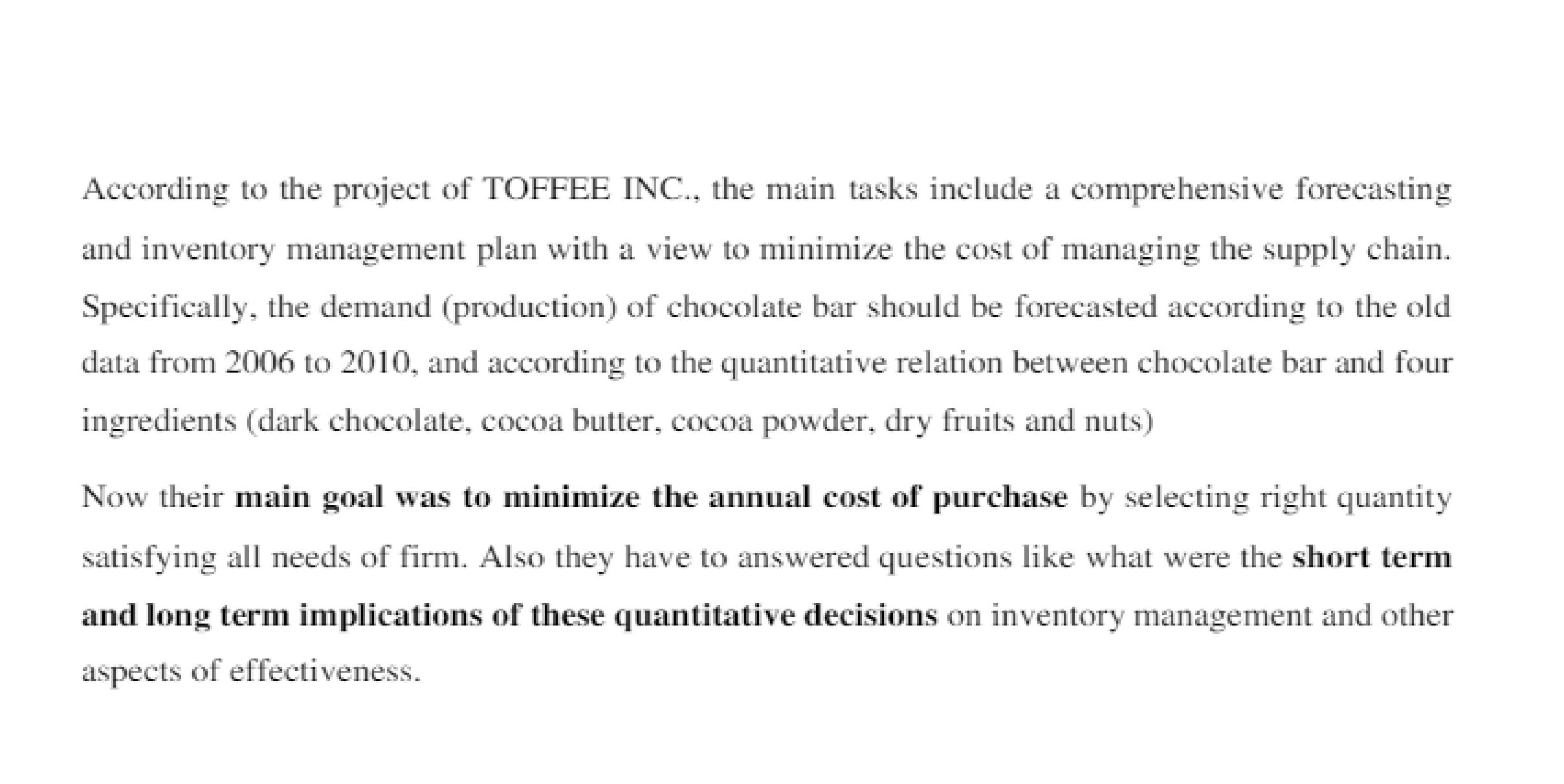

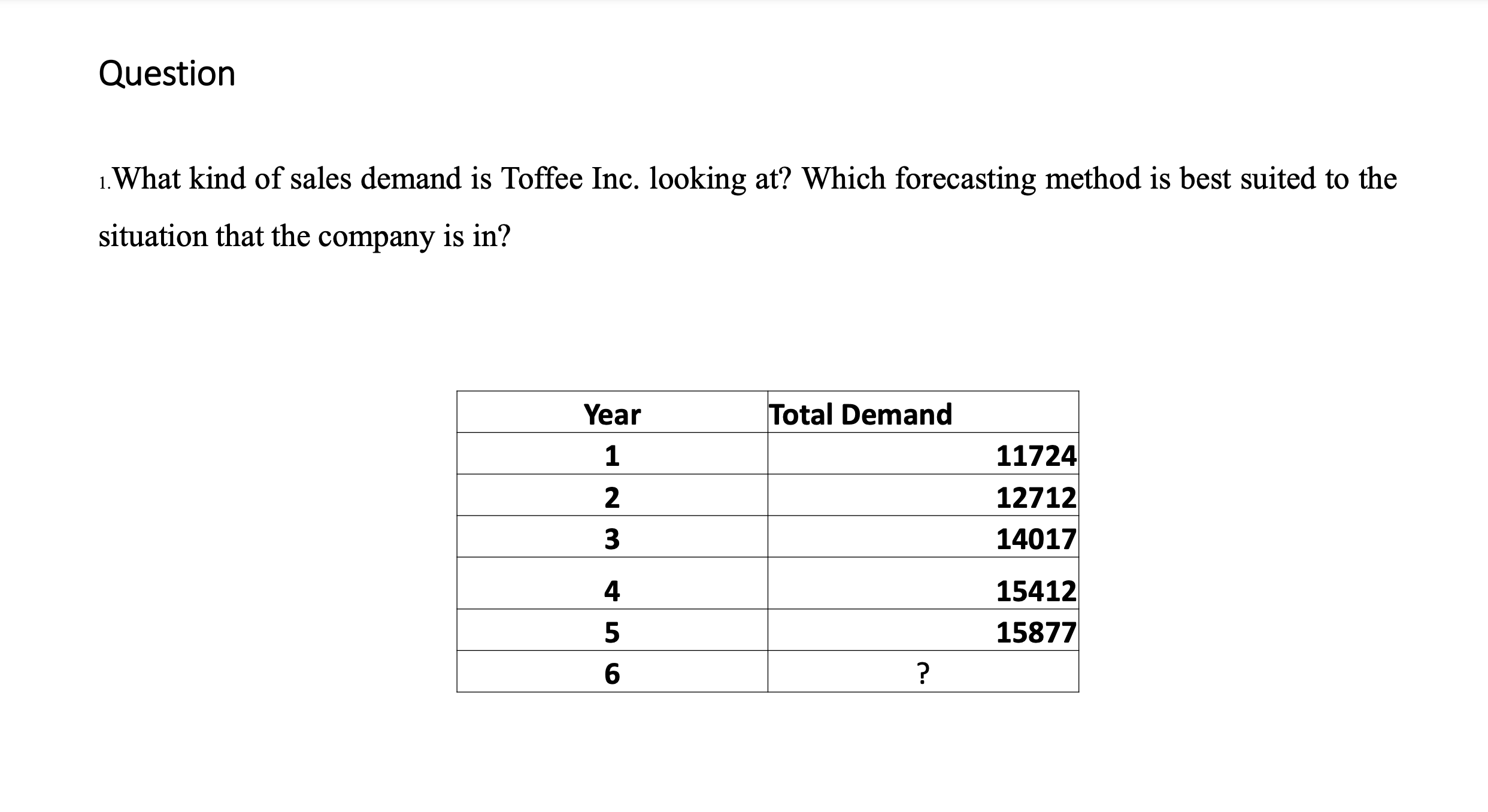

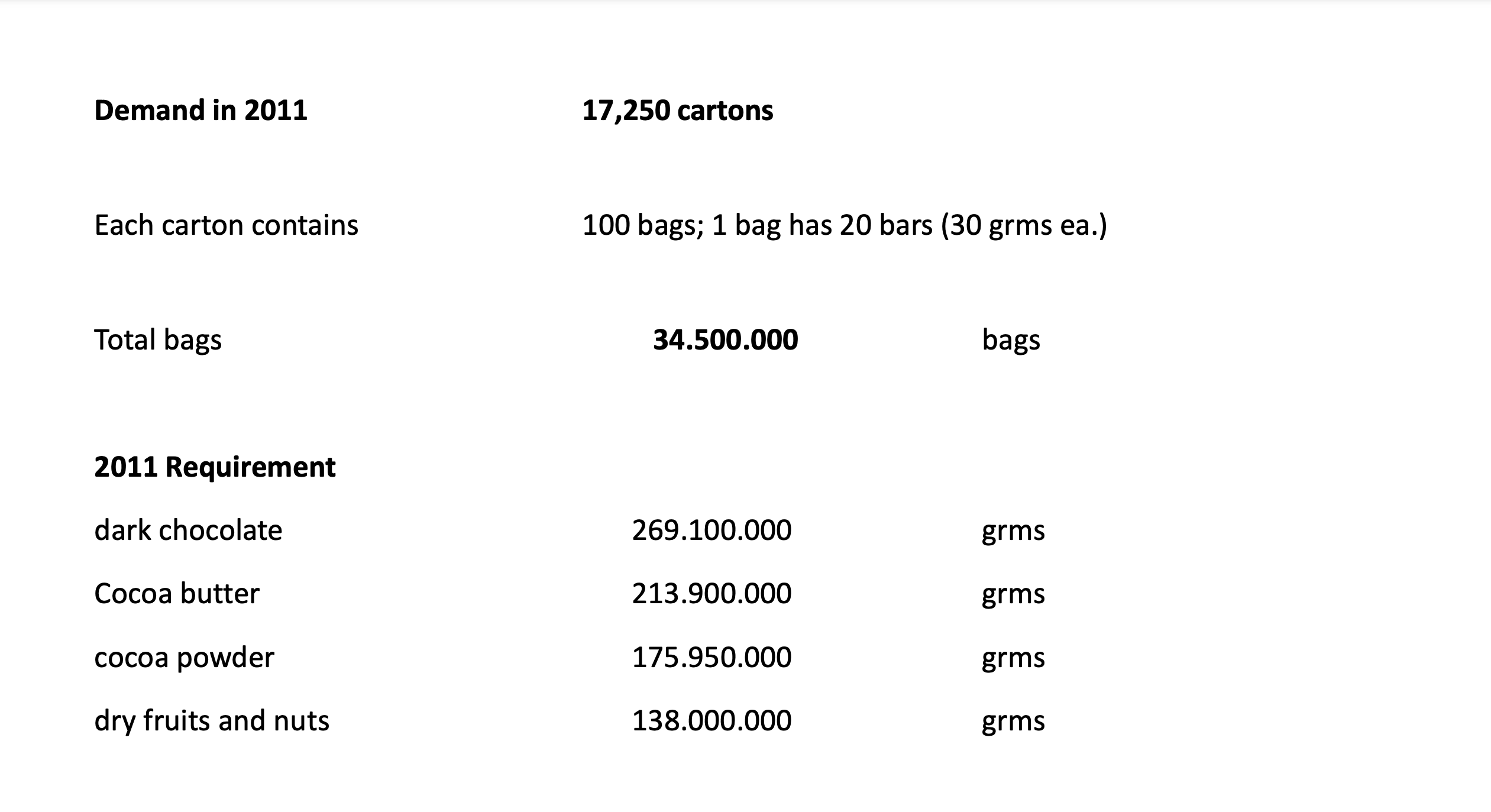

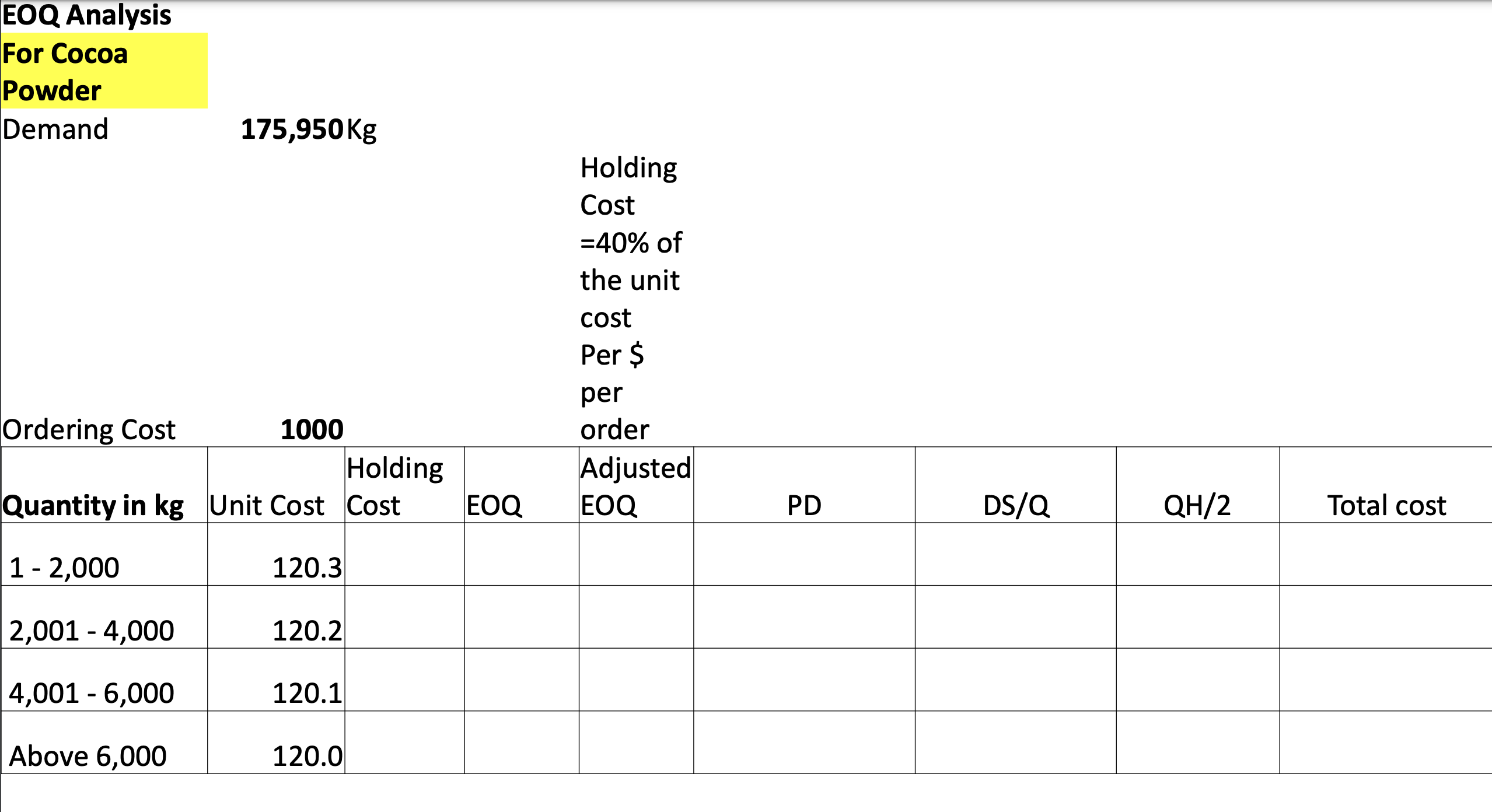

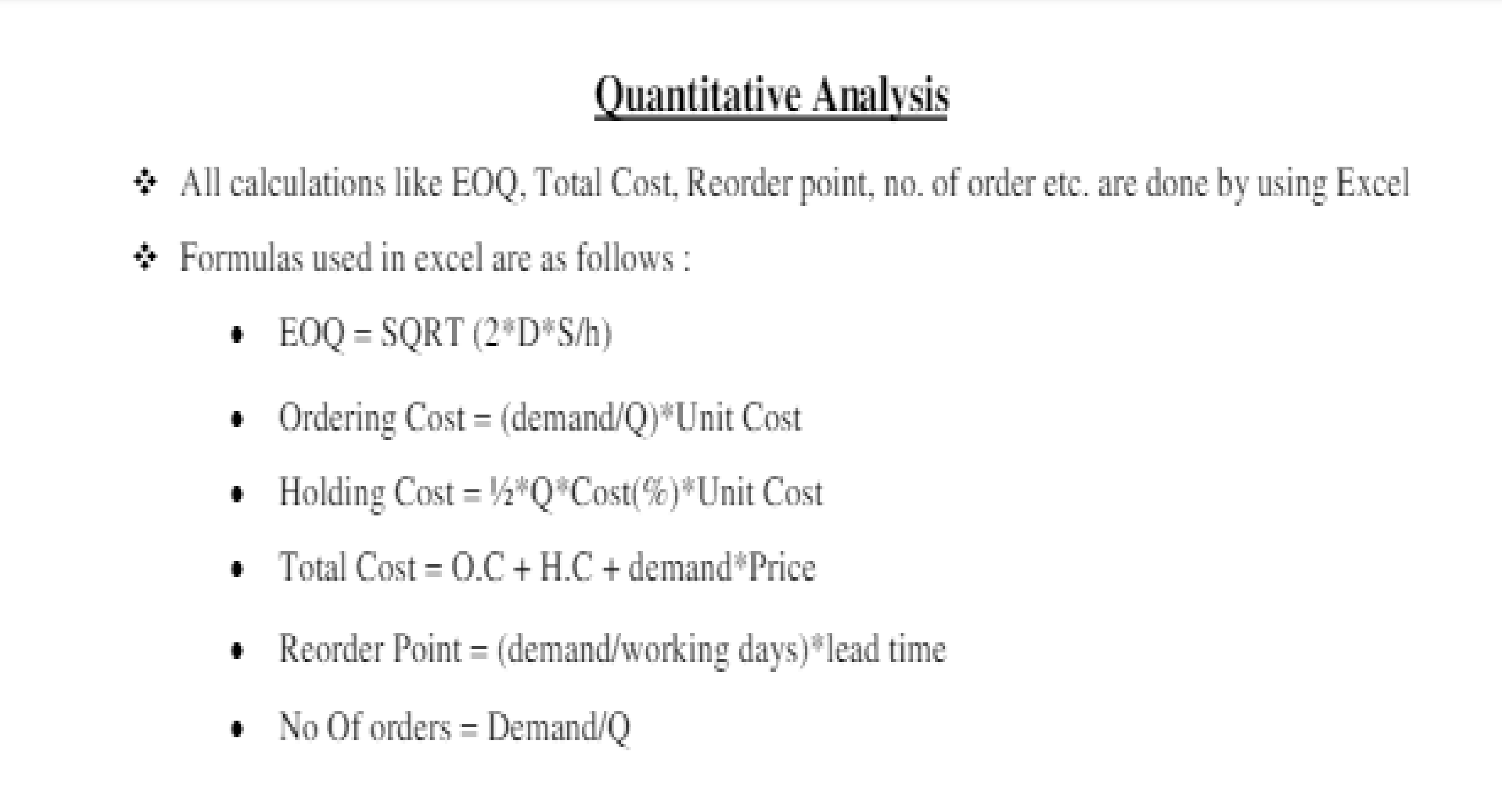

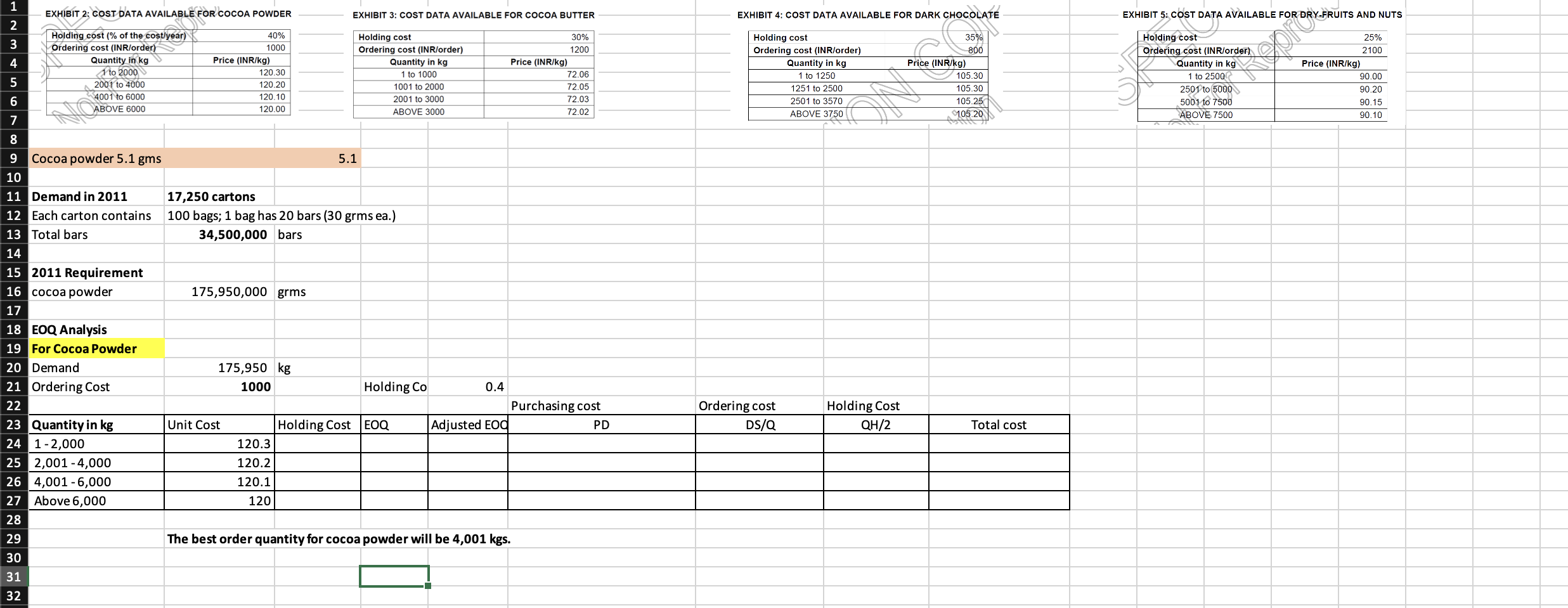

The best order quantity for cocoa powder will be 4,001 kgs. EOQ Analysis For Cocoa Powder Demand 175,950Kg Holding Cost =40% of the unit cost Per \$ per Ordering Cost 1000 order \begin{tabular}{|c|c|c|c|c|c|c|c|c|} \hline Quantity in kg & Unit Cost & \begin{tabular}{l} Holding \\ Cost \end{tabular} & EOQ & \begin{tabular}{l} Adjusted \\ EOQ \end{tabular} & PD & DS/Q & QH/2 & Total cost \\ \hline 12,000 & 120.3 & & & & & & & \\ \hline 2,0014,000 & 120.2 & & & & & & & \\ \hline 4,0016,000 & 120.1 & & & & & & & \\ \hline Above 6,000 & 120.0 & & & & & & & \\ \hline \end{tabular} According to the project of TOFFEE INC., the main tasks include a comprehensive forecasting and inventory management plan with a view to minimize the cost of managing the supply chain. Specifically, the demand (production) of chocolate bar should be forecasted according to the old data from 2006 to 2010, and according to the quantitative relation between chocolate bar and four ingredients (dark chocolate, cocoa butter, cocoa powder, dry fruits and nuts) Now their main goal was to minimize the annual cost of purchase by selecting right quantity satisfying all needs of firm. Also they have to answered questions like what were the short term and long term implications of these quantitative decisions on inventory management and other aspects of effectiveness. Quantitative Analysis * All calculations like EOQ, Total Cost, Reorder point, no. of order etc. are done by using Excel Formulas used in excel are as follows: - EOQ=SQRT(2DS/h) - Ordering Cost =( demand/Q) Unit Cost - Holding Cost =1/20Cost(%) Unit Cost - Total Cost =0.C+HC+ demand Price - Reorder Point =(demand/workingdays) lead time - No Of orders = Demand/Q 1.What kind of sales demand is Toffee Inc. looking at? Which forecasting method is best suited to the situation that the company is in? Demand in 2011 Each carton contains Total bags 2011 Requirement dark chocolate Cocoa butter cocoa powder dry fruits and nuts 17,250 cartons 100 bags; 1 bag has 20 bars ( 30 grms ea.) 34.500 .000 bags 269.100 .000 grms 213.900 .000 grms 175.950 .000 grms 138.000 .000 grms For each of the components 1.What are the reorder points (re-order level) for the sales and distribution division with the given lead time? 2.What is the most economic order quantity for the sales and distribution division? Compute the number of orders per year and the order cycle as well. 3.What is the total annual inventory cost? Assignment Questions 1. What is the production quantity for Seven Star (assuming zero losses in production) and hence, what is the annual requirement for the primary ingredients in terms of quantity needed? 2.What is the best quantity bargain for the firm for various primary ingredients? How are the purchase quantity levels decided and what is the total cost outlay for the same

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts