Question: Please I need all solutions and explanations to this question A distillation column should separate benzene and toluene in a 30 t/h feed flow containing

Please I need all solutions and explanations to this question

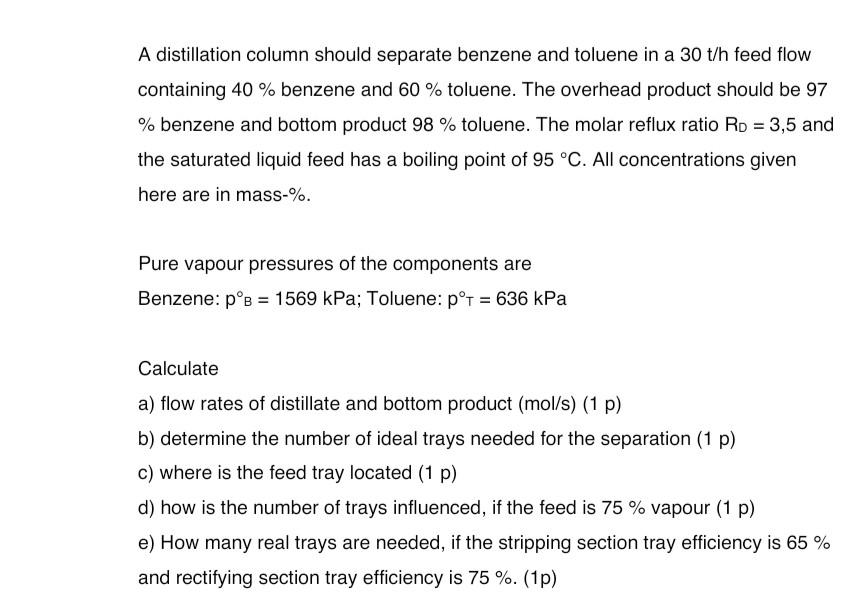

A distillation column should separate benzene and toluene in a 30 t/h feed flow containing 40 % benzene and 60% toluene. The overhead product should be 97 % benzene and bottom product 98 % toluene. The molar reflux ratio RD = 3,5 and the saturated liquid feed has a boiling point of 95 C. All concentrations given here are in mass-%. Pure vapour pressures of the components are Benzene: pB = 1569 kPa; Toluene: pt = 636 kPa Calculate a) flow rates of distillate and bottom product (mol/s) (1 p) b) determine the number of ideal trays needed for the separation (1 p) c) where is the feed tray located (1 p) d) how is the number of trays influenced, if the feed is 75 % vapour (1 p) e) How many real trays are needed, if the stripping section tray efficiency is 65 % and rectifying section tray efficiency is 75 %

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts