Question: please only solve if you know how to solve it in Arena simulation can explan how to (4 points) Orders for street lighting poles require

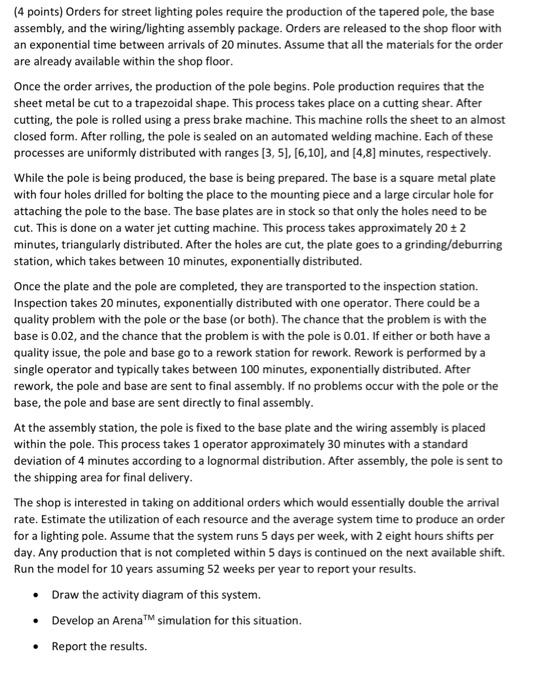

(4 points) Orders for street lighting poles require the production of the tapered pole, the base assembly, and the wiring/lighting assembly package. Orders are released to the shop floor with an exponential time between arrivals of 20 minutes. Assume that all the materials for the order are already available within the shop floor. Once the order arrives, the production of the pole begins. Pole production requires that the sheet metal be cut to a trapezoidal shape. This process takes place on a cutting shear. After cutting, the pole is rolled using a press brake machine. This machine rolls the sheet to an almost closed form. After rolling, the pole is sealed on an automated welding machine. Each of these processes are uniformly distributed with ranges [3, 5), (6,10), and (4,8) minutes, respectively. While the pole is being produced, the base is being prepared. The base is a square metal plate with four holes drilled for bolting the place to the mounting piece and a large circular hole for attaching the pole to the base. The base plates are in stock so that only the holes need to be cut. This is done on a water jet cutting machine. This process takes approximately 2012 minutes, triangularly distributed. After the holes are cut, the plate goes to a grinding/deburring station, which takes between 10 minutes, exponentially distributed. Once the plate and the pole are completed, they are transported to the inspection station. Inspection takes 20 minutes, exponentially distributed with one operator. There could be a quality problem with the pole or the base (or both). The chance that the problem is with the base is 0.02, and the chance that the problem is with the pole is 0.01. If either or both have a quality issue, the pole and base go to a rework station for rework. Rework is performed by a single operator and typically takes between 100 minutes, exponentially distributed. After rework, the pole and base are sent to final assembly. If no problems occur with the pole or the base, the pole and base are sent directly to final assembly. At the assembly station, the pole is fixed to the base plate and the wiring assembly is placed within the pole. This process takes 1 operator approximately 30 minutes with a standard deviation of 4 minutes according to a lognormal distribution. After assembly, the pole is sent to the shipping area for final delivery. The shop is interested in taking on additional orders which would essentially double the arrival rate. Estimate the utilization of each resource and the average system time to produce an order for a lighting pole. Assume that the system runs 5 days per week, with 2 eight hours shifts per day. Any production that is not completed within 5 days is continued on the next available shift. Run the model for 10 years assuming 52 weeks per year to report your results. Draw the activity diagram of this system. Develop an Arena simulation for this situation. Report the results. (4 points) Orders for street lighting poles require the production of the tapered pole, the base assembly, and the wiring/lighting assembly package. Orders are released to the shop floor with an exponential time between arrivals of 20 minutes. Assume that all the materials for the order are already available within the shop floor. Once the order arrives, the production of the pole begins. Pole production requires that the sheet metal be cut to a trapezoidal shape. This process takes place on a cutting shear. After cutting, the pole is rolled using a press brake machine. This machine rolls the sheet to an almost closed form. After rolling, the pole is sealed on an automated welding machine. Each of these processes are uniformly distributed with ranges [3, 5), (6,10), and (4,8) minutes, respectively. While the pole is being produced, the base is being prepared. The base is a square metal plate with four holes drilled for bolting the place to the mounting piece and a large circular hole for attaching the pole to the base. The base plates are in stock so that only the holes need to be cut. This is done on a water jet cutting machine. This process takes approximately 2012 minutes, triangularly distributed. After the holes are cut, the plate goes to a grinding/deburring station, which takes between 10 minutes, exponentially distributed. Once the plate and the pole are completed, they are transported to the inspection station. Inspection takes 20 minutes, exponentially distributed with one operator. There could be a quality problem with the pole or the base (or both). The chance that the problem is with the base is 0.02, and the chance that the problem is with the pole is 0.01. If either or both have a quality issue, the pole and base go to a rework station for rework. Rework is performed by a single operator and typically takes between 100 minutes, exponentially distributed. After rework, the pole and base are sent to final assembly. If no problems occur with the pole or the base, the pole and base are sent directly to final assembly. At the assembly station, the pole is fixed to the base plate and the wiring assembly is placed within the pole. This process takes 1 operator approximately 30 minutes with a standard deviation of 4 minutes according to a lognormal distribution. After assembly, the pole is sent to the shipping area for final delivery. The shop is interested in taking on additional orders which would essentially double the arrival rate. Estimate the utilization of each resource and the average system time to produce an order for a lighting pole. Assume that the system runs 5 days per week, with 2 eight hours shifts per day. Any production that is not completed within 5 days is continued on the next available shift. Run the model for 10 years assuming 52 weeks per year to report your results. Draw the activity diagram of this system. Develop an Arena simulation for this situation. Report the results

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts