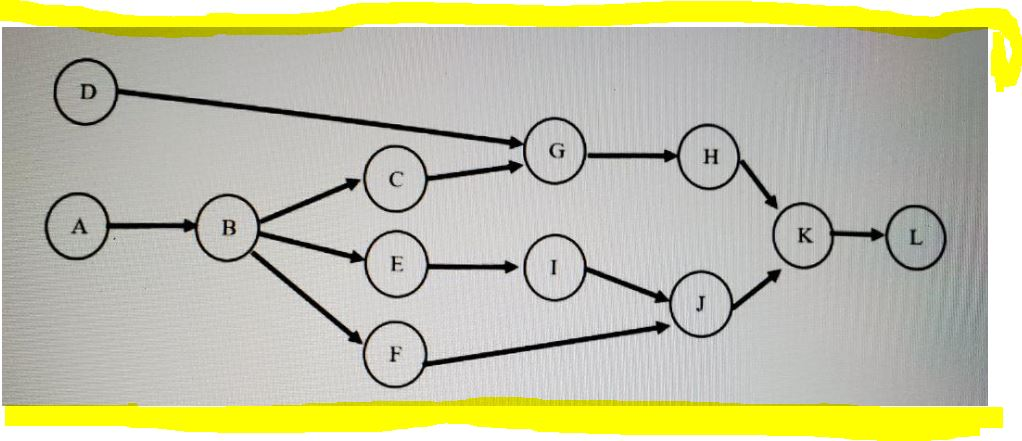

Question: PLEASE ONLY SOLVE PART (c). Parts (a) and (b) are already completed with answers shown. See the Assembly line below with the following 12 tasks.

PLEASE ONLY SOLVE PART (c). Parts (a) and (b) are already completed with answers shown.

See the Assembly line below with the following 12 tasks. The desired # of output is 50 units per day. Balance the assembly line--->Answer parts (a) & (b).

Assume that the system works continuously for 10 hours each day.

| Task | Task Time (minutes) | Preceding task(s) |

| A | 10 | - |

| B | 4 | A |

| C | 6 | B |

| D | 5 | - |

| E | 7 | B |

| F | 9 | B |

| G | 5 | C, D |

| H | 4 | G |

| I | 2 | E |

| J | 3 | I, F |

| K | 5 | H, J |

| L | 6 | K |

PLEASE ONLY SOLVE PART (c). Parts (a) and (b) are already completed with answers shown.

Part (a):

Determine the cycle time (in minutes) for the desired output rate per day.

ANSWER: Cycle time = Time in a day / demand = 10 hours / 50 = 0.20 hours or 0.2*60 = 12 minutes

Part (b):

Balance the line by using the RULE #1: "most number of following task" and then as a SECONDARY RULE: use "shortest operation time" (as a secondary criterion).

Write the sequence of each task in each workstation.

part B) ANSWER:

| Workstation | task assigned | sum of task time | rationale |

| 1 | A | 10 | A is the starting task and no other task can be assigned as cycle time is 12 minutes |

| 2 | B-D | 9 | B has most number of following task and D has shorter operating time compared to C/E/F |

| 3 | C-G | 11 | c has shorter operating time and only g can be assigned to station |

| 4 | E-I | 9 | E has shorter operating time than F |

| 5 | F-J | 12 | |

| 6 | H-K | 9 | |

| 7 | L | 6 |

part (c) What is the total idle time?

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts