Question: please provide all the answers Done Project Management Case Studies (9... The Need for Project Management Metrics (H) NEED FOR CAPACITY METRICS Frosperity never comes

please provide all the answers

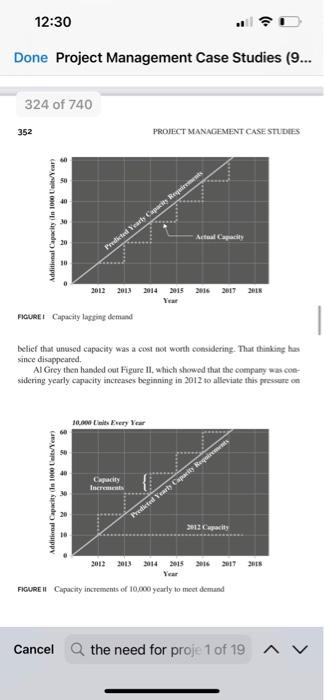

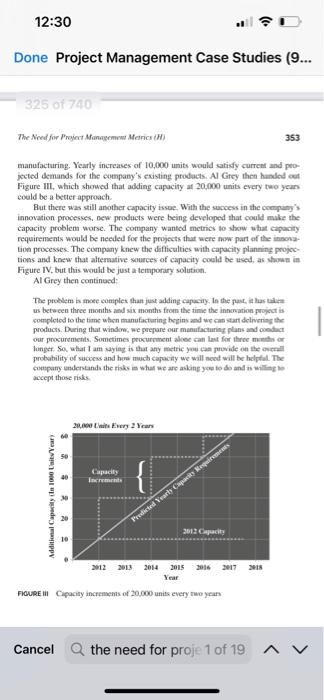

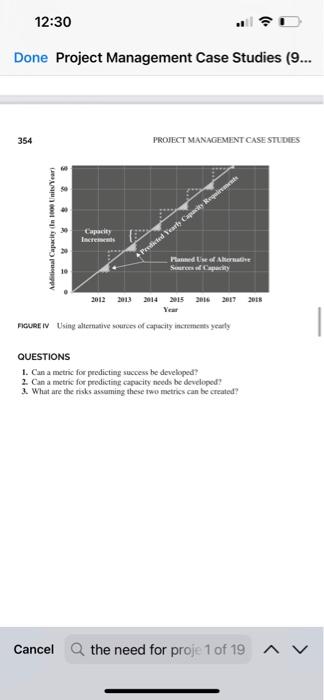

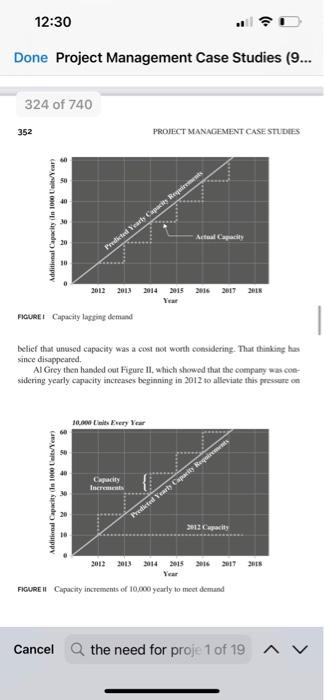

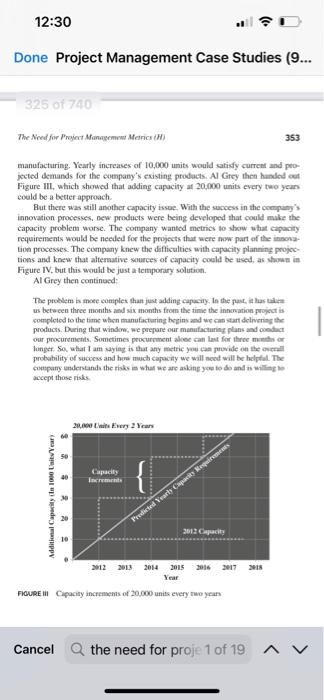

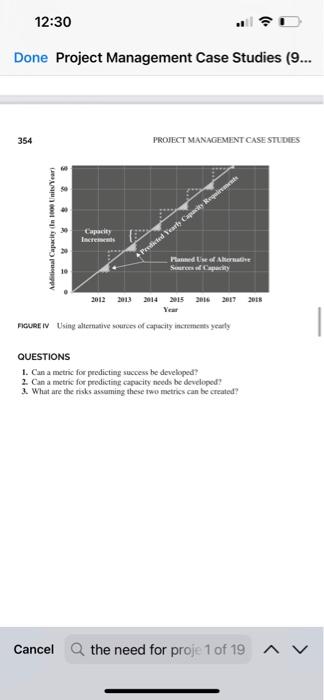

Done Project Management Case Studies (9... The Need for Project Management Metrics (H) NEED FOR CAPACITY METRICS Frosperity never comes withoul headaches. The new metrics measurcincmit system was working quaite well. Some peojects were canceled, as expected, and most of the projects that went throught to completion were eansidered successec. Actially, the company was becoming more successful than it had criginally boped and this was placing a strain on manufacturing capaciry. Al Grey convened the metrics manupemett team once apain to see if any Aitics coeld be created to assist with capacity planning. He saacd. As you all know, the company has been etlatively conervative in the pest a ofen it tame to adling moee ittanufacturing capacity, Sometimes we were toe eotseraing perscenel are working evertime asd weckends to try fo keep wi with dcmand jects in the queue. Are there any metrics we can develap and ase durief corr Al Gircy handed our Figure I and explained that, with the existing prodocts in zanufacturing, capakity would be lageing demand by almorst 10,000 a-its per year beginning in 2012 . The conservative nature of the company was based on the Done Project Management Case Studies (9... 352 PROHECT MANMCFMANCASE STUTIES Focuset Capacity laiging demand belief than untised capacity was a cost not worth considering. That thinking has since disappeared. Al Grey then handed cat Figure 11. which showed that the coenpany was coesidering yearly capacity increases beginning in 2012 to alleviate this pressare on The Areal for Proiect Manwermone Mesnics iH| 353 manufacturing. Yearly increases of 10,000 units would safisfy current and proxected demands for the eumpany's existing prodacts. Al Girey then handed out Figure III, which shored that adding capacity at 20,000 units every teo yean coald be a better approach. But there was still another capacity issac. With the success in the coerpany's innovation processes, new products were being developed that could make the capacity problem worse. The company wantcd metrics to show what capaciny requirements would be needed foe the projects that were now part of the insoraLion processes. The company knew the difliculties with capacily planning projecbions and knew that altermative sources of capacity coald be used, as shown in Figure IV. but this would be just a temporary solution. Al Grey then continued: The proelem is maec complet than just adding capucily. In the fast, in las talier us betw cen three months and six months from the time the innowation project is completed to the time when manufacturing hegins and we cat start delivering the products. During that windorw, we prepare our manufacturing plans and oondact our procurements, Sometimes peocurcment alcee sat last for throe moeth or longer. So, what 1 am saying is that any metric yoe tas provide on the overal probability of sucocss and hum much capac ity we will nced will be halptal The codrpany endertands the rivks = what we are atking ycen fo do and is will-r bo accept those risks. Done Project Management Case Studies (9... 354 PROUECT MANACTMENT CASE STITEES Ficuke W Using altranative montes of capacity incrumeats yealy QUESTIONS 1. Can a metric for peedictiog success be developed? 2. Can a metric for predictitug capacity needs be developed? 3. What are the risks assaming these two metrics can be created

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock