Question: Please read the case and answer the questions , i will write excellent comments, Thank you in advance Sember 2010 Schuhe, vice president of nocturer

Please read the case and answer the questions , i will write excellent comments, Thank you in advance

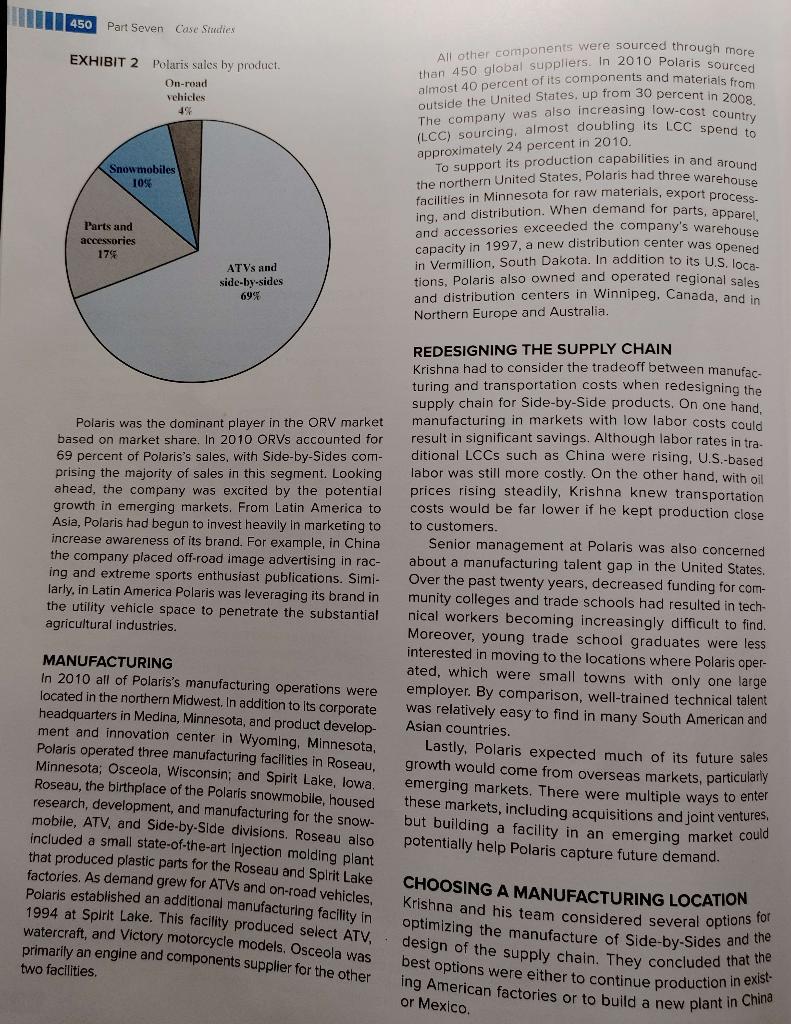

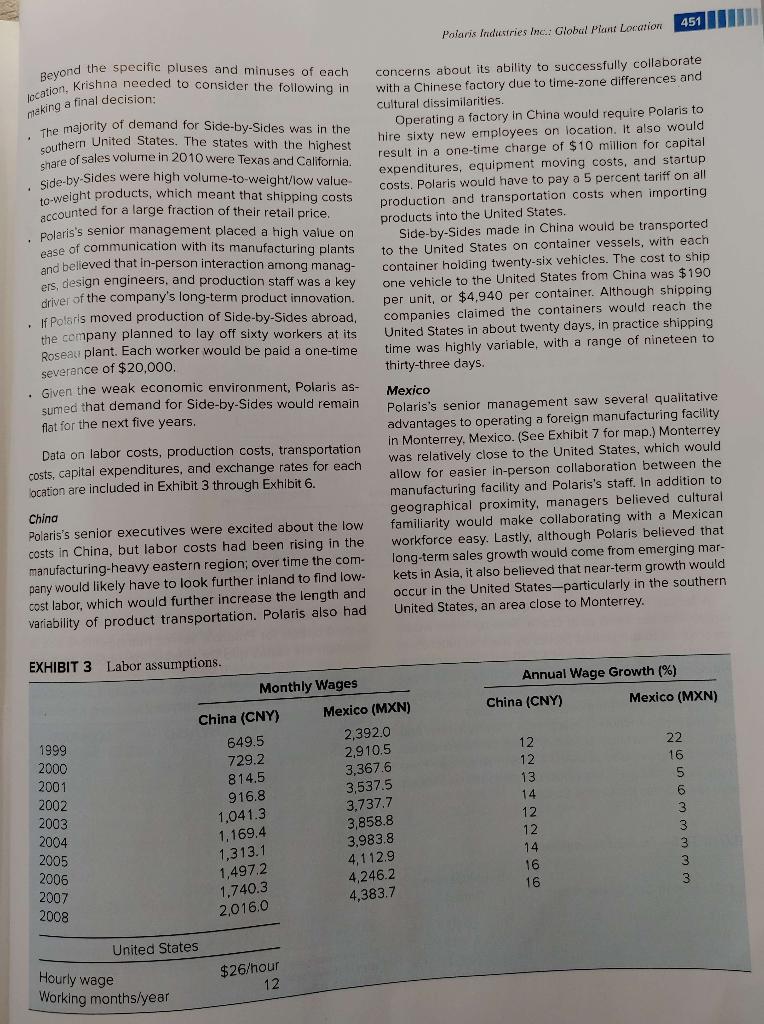

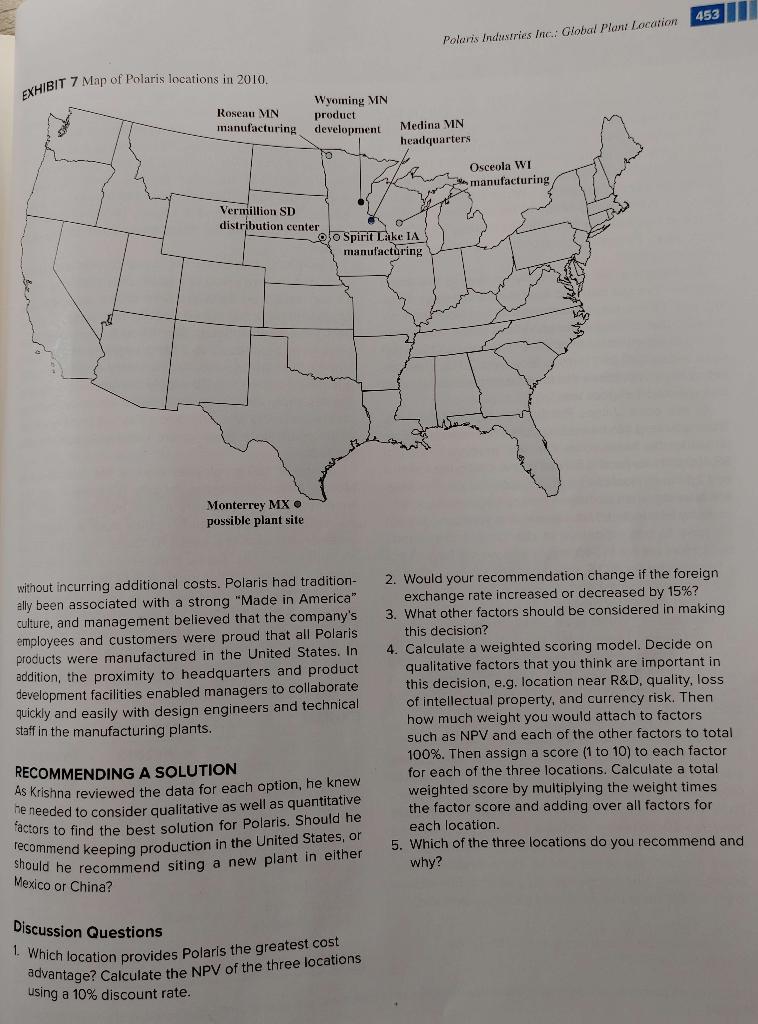

Sember 2010 Schuhe, vice president of nocturer of altors ATV Side by Sidst dions and integration at Poins Industrien mo sa isothion Mod Mines barsting the recordion he was developing for pant to manufacture the companys 50e-by-Side are developed solely as the basis for class die onded to serve endorsements of myota Astration effective ar inoffective manage No paths pubicon may be reproduced, piny wed in a spreadsheet or transmitted in any font or by any moment mechanical congrecording of One without the permission of the Revlogo School of Management med with permission his See Exo 1 for pictures of Police Case Study Polaris Industrles Inc.: Global Plant I ocation mu - ch Kelky EXHIBIT 1 Polaris velictes ATV The owdown in the scales had topon Pow's wrots, 16 the com Descondering whether it should followed of of its competitors and open a factity in Cory with loweriboto China and Medicare a shisted as possible location for the new factory which would be the finit Polos mandeling city located outsiden Unise By the und of the needed to recommend to CEO sco Wine and the bed of directors whether in shoudbuildew part od or conta turints American focities POLARIS INDUSTRIES INC Established in 1954. Poissantren performance motorsport products, ATS by Sides, and somobiles See Ext2 for Polaris sales by products with nearly $2 billion instein 2010 It was a strong player in the $10 bilion power sports market alongside competitors Yamaha Honda Arctic Cat Ski-Doo, and Harley Davidson Polaris's customers were primarily located in Norm America 95 percent is intentional customers were concentrated in Europe Foreign markets were becon Ing increasingly mportant to Polans Internal reve nu had grown 21 percent in 2010, and was forecasted to grow even more in 2011. Polaris products were sold through 4,500 distributors in the United States and 1.000 distributors in the rest of the world. Polaris's heritage was deeply rooted in the power sports industry. The company introduced its first sowo ble in the 1950s and its first ATV 1985. Between 1995 and 2010 Polar Sold more than two milion ATVs in Side by Side wala Snowmobile 1992 Polaris entered the personal watercraft morset but it lacked a sustainable distribution system and exited the business in 2004. In 1998 the compony introduced the Krst Side-by-Side arrond vehicle ORVI, which was expected to surpas ATV sale during 2011. Also in 1998 Polariserired the parts, accessories, and apparel seg ment, which grew significantly over the next decade Finally Polaris also introduced its first onoad vehicle 1998- motorcycle with the brand name "Victory-10 compete with Harley Davidson Combined these products were forecasted to bring in $2.2 bilion revenue in 2011 Polans's total revenue grew more than 20 percent in 2010 and was expected to grow 8 to 11 percent i 2011 Beat Heidely Saskim Side by Side vehicles were similar 10 ATVs but had a steering wheel and torgeted tiltarian customer segments such as torm 8. muillcre homeowners, and the mitary 2012 by the Kellopo School of Management et Northwestern University. This coe was prepared by an Andreas 12.Sormad Sice 12. Kos 12 Stephane hoste 12 and Benjamin Neuwirth 12 tinder respon of Professor School Ch. 449 111 ing American factories or to build a new plant in China percent in All other components were sourced through more than 450 global suppliers. In 2010 Polaris sourced almost 40 percent of its components and materials from outside the United States, up from 30 percent in 2008 appre Sourcing, almost doubling its LCC spend to To support its production capabilities in and around accessories exceeded the company's warehouse capacity in 1997, a new distribution center was opened design of the supply chain. They concluded that the best options were either to continue production in exist- 450 Part Seven Case Studies EXHIBIT 2 Polaris sales by product. On-road vehicles 4% was also increasing low-cost country The company () 24 in 2010 Snowmobiles 10% the northern United States, Polaris had three warehouse facilities in Minnesota for raw materials, export process Parts and ing, and distribution. When demand for parts, apparel. accessories and 17% ATVs and in Vermillion, South Dakota. In addition to its U.S. loca- side-by-sides tions, Polaris also owned and operated regional sales 69% and distribution centers in Winnipeg, Canada, and in Northern Europe and Australia. Polaris was the dominant player in the ORV market based on market share. In 2010 ORVs accounted for 69 percent of Polaris's sales, with Side-by-Sides com- prising the majority of sales in this segment. Looking ahead, the company was excited by the potential growth in emerging markets. From Latin America to Asia, Polaris had begun to invest heavily in marketing to increase awareness of its brand. For example, in China the company placed off-road image advertising in rac- ing and extreme sports enthusiast publications. Simi- larly, in Latin America Polaris was leveraging its brand in the utility vehicle space to penetrate the substantial agricultural industries. REDESIGNING THE SUPPLY CHAIN Krishna had to consider the tradeoff between manufac- turing and transportation costs when redesigning the supply chain for Side-by-Side products. On one hand, manufacturing in markets with low labor costs could result in significant savings. Although labor rates in tra- ditional LCCs such as China were rising, U.S.-based labor was still more costly. On the other hand, with oil prices rising steadily, Krishna knew transportation costs would be far lower if he kept production close to customers. Senior management at Polaris was also concerned about a manufacturing talent gap in the United States. Over the past twenty years, decreased funding for com- munity colleges and trade schools had resulted in tech- nical workers becoming increasingly difficult to find. Moreover, young trade school graduates were less interested in moving to the locations where Polaris oper- ated, which were small towns with only one large employer. By comparison, well-trained technical talent was relatively easy to find in many South American and Asian countries. Lastly, Polaris expected much of its future sales growth would come from overseas markets, particularly emerging markets. There were multiple ways to enter these markets, including acquisitions and joint ventures, but building a facility in an emerging market could potentially help Polaris capture future demand. MANUFACTURING In 2010 all of Polaris's manufacturing operations were located in the northern Midwest. In addition to its corporate headquarters in Medina, Minnesota, and product develop- ment and innovation center in Wyoming, Minnesota, Polaris operated three manufacturing facilities in Roseau, Minnesota: Osceola, Wisconsin; and Spirit Lake, lowa. Roseau, the birthplace of the Polaris snowmobile, housed research, development, and manufacturing for the snow- mobile, ATV, and Side-by-Side divisions. Roseau also included a small state-of-the-art Injection molding plant that produced plastic parts for the Roseau and Spirit Lake factories. As demand grew for ATVs and on-road vehicles, Polaris established an additional manufacturing facility in 1994 at Spirit Lake. This facility produced select ATV, watercraft, and Victory motorcycle models. Osceola was primarily an engine and components supplier for the other two facilities. CHOOSING A MANUFACTURING LOCATION Krishna and his team considered several options for optimizing the manufacture of Side-by-Sides and the or Mexico 451 Polaris Industries Inc.: Global Piant Location Beyond the specific pluses and minuses of each location, Krishna needed to consider the following in The majority of demand for Side-by-Sides was in the southern United States. The states with the highest share of sales volume in 2010 were Texas and California. Side-by-Sides were high volume-to-weight/low value to-weight products, which meant that shipping costs Polaris's senior management placed a high value on accounted for a large fraction of their retail price, making a final decision: ease of communication with its manufacturing plants and believed that in-person interaction among manag- ers, design engineers, and production staff was a key driver of the company's long-term product innovation . If Polaris moved production of Side-by-Sides abroad, the company planned to lay off sixty workers at its Roseau plant. Each worker would be paid a one-time severance of $20,000 . Given the weak economic environment, Polaris as- sumed that demand for Side-by-Sides would remain flat for the next five years. concerns about its ability to successfully collaborate with a Chinese factory due to time-zone differences and cultural dissimilarities. . Operating a factory in China would require Polaris to hire sixty new employees on location. It also would result in a one-time charge of $10 million for capital expenditures, equipment moving costs, and startup costs. Polaris would have to pay a 5 percent tariff on all production and transportation costs when importing products into the United States. Side-by-Sides made in China would be transported to the United States on container vessels, with each container holding twenty-six vehicles. The cost to ship one vehicle to the United States from China was $190 per unit, or $4,940 per container. Although shipping companies claimed the containers would reach the United States in about twenty days, in practice shipping time was highly variable, with a range of nineteen to thirty-three days. Mexico Polaris's senior management saw several qualitative advantages to operating a foreign manufacturing facility in Monterrey, Mexico. (See Exhibit 7 for map.) Monterrey was relatively close to the United States, which would allow for easier in-person collaboration between the manufacturing facility and Polaris's staff. In addition to geographical proximity, managers believed cultural familiarity would make collaborating with a Mexican workforce easy. Lastly, although Polaris believed that long-term sales growth would come from emerging mar- kets in Asia, it also believed that near-term growth would occur in the United States-particularly in the southern United States, an area close to Monterrey. Data on labor costs, production costs, transportation costs, capital expenditures, and exchange rates for each location are included in Exhibit 3 through Exhibit 6. China Polaris's senior executives were excited about the low costs in China, but labor costs had been rising in the manufacturing-heavy eastern region; over time the com- pany would likely have to look further inland to find low- cost labor, which would further increase the length and variability of product transportation. Polaris also had EXHIBIT 3 Labor assumptions. Annual Wage Growth (%) China (CNY) Mexico (MXN) 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 Monthly Wages China (CNY) Mexico (MXN) 649.5 2,392.0 729.2 2.910.5 814,5 3,367.6 916.8 3,537.5 1,041.3 3.737.7 1,169.4 3,858.8 1,313.1 3.983.8 4,112.9 1.740.3 4,246.2 2,016.0 4,383.7 12 12 13 14 12 12 14 16 16 1,497.2 3 United States Hourly wage Working months/year $26/hour 12 453 Polaris Industries Inc.. Global Plant Location EXHIBIT 7 Map of Polaris locations in 2010. Wyoming MN Roseau MN product manufacturing development Medina MN headquarters Osceola WI manufacturing Vermillion SD distribution center O Spirit Lake IA manufacturing Monterrey MX O possible plant site without incurring additional costs. Polaris had tradition- ally been associated with a strong "Made in America" culture, and management believed that the company's employees and customers were proud that all Polaris products were manufactured in the United States. In addition, the proximity to headquarters and product development facilities enabled managers to collaborate quickly and easily with design engineers and technical staff in the manufacturing plants. 2. Would your recommendation change if the foreign exchange rate increased or decreased by 15%? 3. What other factors should be considered in making this decision? 4. Calculate a weighted scoring model. Decide on qualitative factors that you think are important in this decision, e.g. location near R&D, quality, loss of intellectual property, and currency risk. Then how much weight you would attach to factors such as NPV and each of the other factors to total 100%. Then assign a score (1 to 10) to each factor for each of the three locations. Calculate a total weighted score by multiplying the weight times the factor score and adding over all factors for each location. 5. Which of the three locations do you recommend and why? RECOMMENDING A SOLUTION As Krishna reviewed the data for each option, he knew he needed to consider qualitative as well as quantitative factors to find the best solution for Polaris. Should he recommend keeping production in the United States, or should he recommend siting a new plant in either Mexico or China? Discussion Questions Which location provides Polaris the greatest cost advantage? Calculate the NPV of the three locations using a 10% discount rateStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts