Question: please show formulas OR rationale please! Consider a supply chain consisting of one retailer and one supplier (a manufacturer). The retailer manages an inventory of

please show formulas OR rationale please!

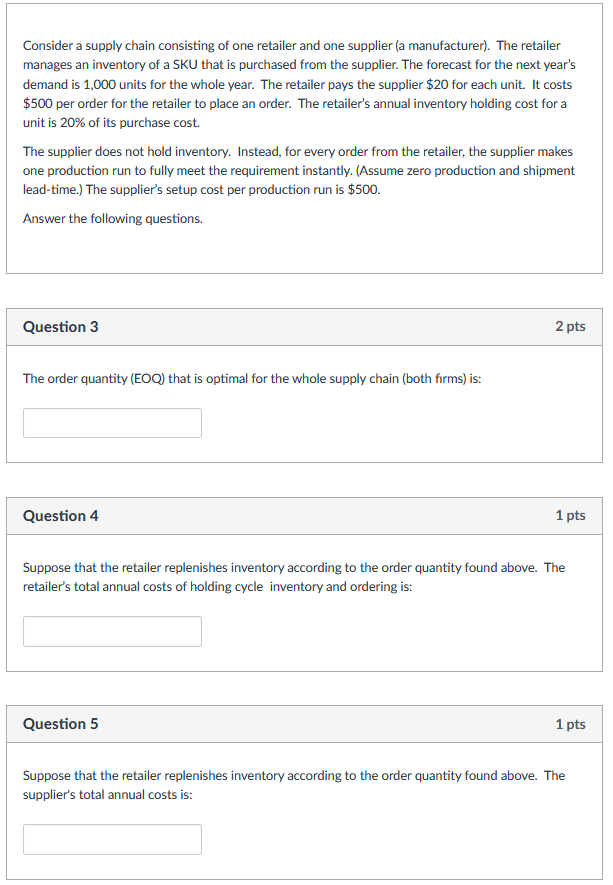

Consider a supply chain consisting of one retailer and one supplier (a manufacturer). The retailer manages an inventory of a SKU that is purchased from the supplier. The forecast for the next year's demand is 1,000 units for the whole year. The retailer pays the supplier $20 for each unit. It costs $500 per order for the retailer to place an order. The retailer's annual inventory holding cost for a unit is 20% of its purchase cost. The supplier does not hold inventory. Instead, for every order from the retailer, the supplier makes one production run to fully meet the requirement instantly. (Assume zero production and shipment lead-time.) The supplier's setup cost per production run is $500. Answer the following questions. Question 3 2 pts The order quantity (EOQ) that is optimal for the whole supply chain (both forms) is: Question 4 1 pts Suppose that the retailer replenishes inventory according to the order quantity found above. The retailer's total annual costs of holding cycle inventory and ordering is: Question 5 1 pts Suppose that the retailer replenishes inventory according to the order quantity found above. The supplier's total annual costs isStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock