Question: Please show work in Excel. a. Build an optimization model to determine the quantity of each pattern to cut to meet demand with minimum total

Please show work in Excel.

a. Build an optimization model to determine the quantity of each pattern to cut to meet demand with minimum total (edge plus end) waste cost. Assume that the rolls are much longer than the total quantities being cut, so you wont run out of material with any patter.

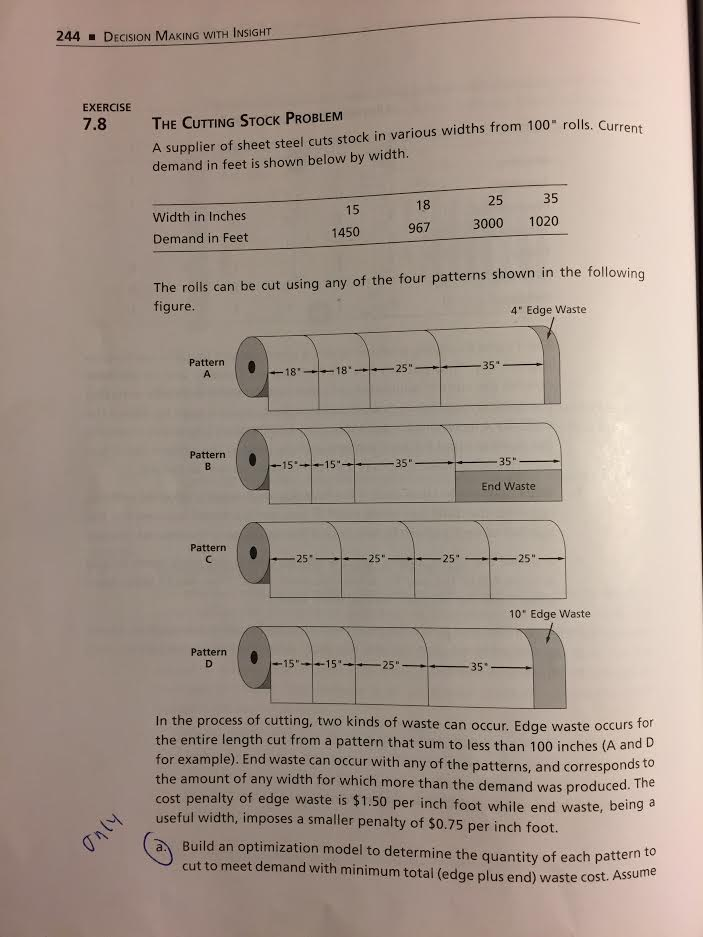

244 DECISION MAKING WITH INSIGHT EXERCISE A supplier of sheet steel cuts stock in various widths from 100" rolls. Cur demand in feet is shown below by width. 7.8 THE CUTTING STOCK PROBLEM 25 35 18 Width in Inches 967 3000 1020 1450 Demand in Feet The rolls can be cut using any of the four patterns shown in the following figure 4" Edge Waste Pattern 18" 25"35 18* Pattern -15-15 35 35 End Waste Pattern 25" 10" Edge Waste Pattern -15-1525"35 In the process of cutting, two kinds of waste can occur. Edge waste occurs for the entire length cut from a pattern that sum to less than 100 inches (A and D for example). End waste can occur with any of the patterns, and correspond the amount of any width for which more than the demand was produc cost penalty of edge waste is $1.50 per inch foot while end waste, being useful width, imposes a smaller penalty of $0.75 per inch foot. an optimization model to determine the quantity of each pattern to Assume a Build cut to meet demand with minimum total (edge plus end) waste cost. 244 DECISION MAKING WITH INSIGHT EXERCISE A supplier of sheet steel cuts stock in various widths from 100" rolls. Cur demand in feet is shown below by width. 7.8 THE CUTTING STOCK PROBLEM 25 35 18 Width in Inches 967 3000 1020 1450 Demand in Feet The rolls can be cut using any of the four patterns shown in the following figure 4" Edge Waste Pattern 18" 25"35 18* Pattern -15-15 35 35 End Waste Pattern 25" 10" Edge Waste Pattern -15-1525"35 In the process of cutting, two kinds of waste can occur. Edge waste occurs for the entire length cut from a pattern that sum to less than 100 inches (A and D for example). End waste can occur with any of the patterns, and correspond the amount of any width for which more than the demand was produc cost penalty of edge waste is $1.50 per inch foot while end waste, being useful width, imposes a smaller penalty of $0.75 per inch foot. an optimization model to determine the quantity of each pattern to Assume a Build cut to meet demand with minimum total (edge plus end) waste cost

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts