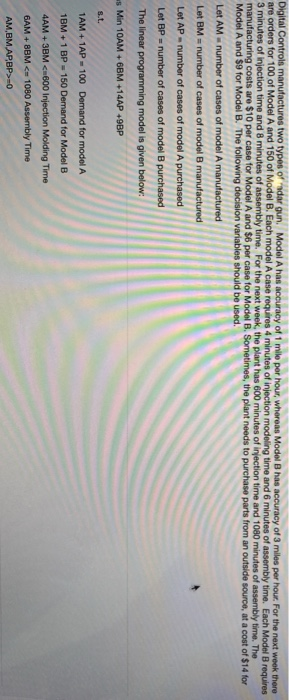

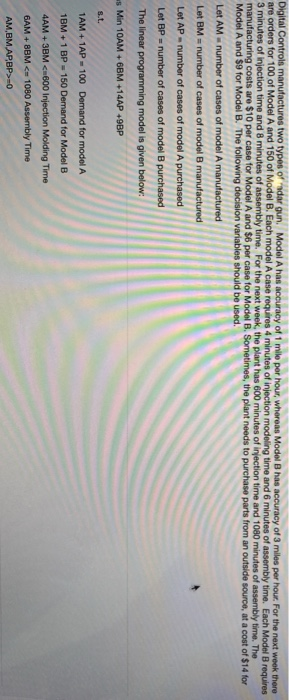

Question: Please solve. All one problem Digital Controls manufactures two types of adar gun. Model A has accuracy of 1 mile per hour, whereas Model B

Please solve. All one problem

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock