Question: please solve it immediatly please procces and integration for sustaiable design A fresh feed of 10,000kg/hr of acetic acid AA along with 200kg/hr of water

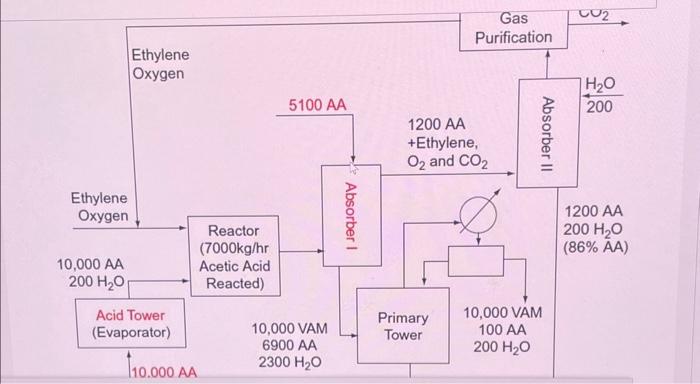

A fresh feed of 10,000kg/hr of acetic acid "AA" along with 200kg/hr of water are evaporated in an acid tower. The vapor is fed with oxygen and ethylene to the reactor where 7000kg/g of acetic acid are reacted and 10,000kg/hr of VAM are formed. The reactor off-gas is cooled and fed to first absorber, where AA (5100kg/hr) is used as a solvent. Almost all the gases leave from the top of the first absorption column, together with 1200kg/hr of AA. This stream is fed to the second absorption column where water (200 kg/hr) is used to scrub acetic acid. The bottom product of the first absorption column is fed to the primary distillation tower, where VAM is recovered as a top product (10,000kg/hr) along with 200kg/hr of water and a small amount of AA (100kg/hr), which is not economically justifiable to recover. This stream is sent to final finishing. The bottom product of the primary tower ( 6800kg/hr of AA and 2300kg/hr of water) is mixed with the bottom product of the second absorption column ( 1200kg/hr of AA and 200kg/hr of water). The mixed waste is fed to a neutralization system followed by biotreatment. In this example, let us consider the case when no changes are made to the consumption by chemical reaction and there are no adjustments in design or operating conditions to reduce fresh AA consumption. What is the target for minimum fresh usage and minimum terminal losses of AA

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts