Question: PLEASE SOLVE ONLY SEND OPL CODE FatCat Company manufactures pool tables using four main components: a slate, a felt, four legs, and a cue holder.

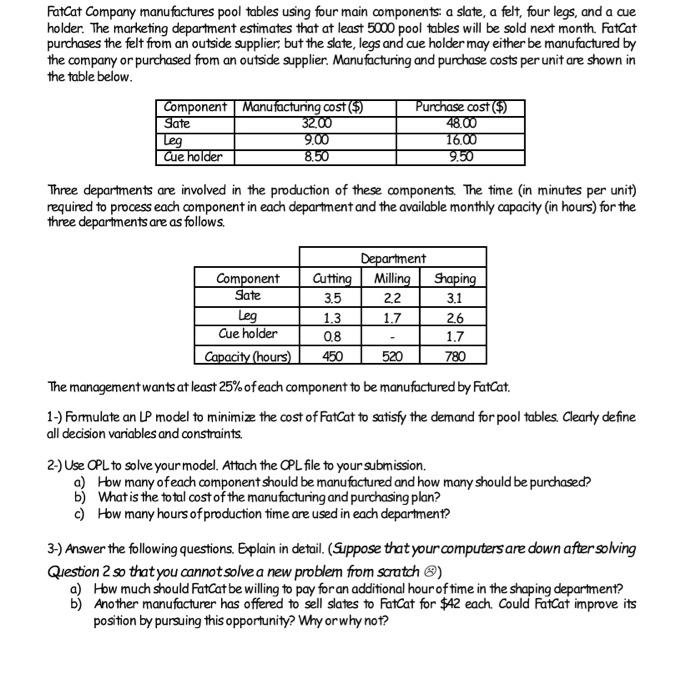

FatCat Company manufactures pool tables using four main components: a slate, a felt, four legs, and a cue holder. The marketing department estimates that at least 5000 pool tables will be sold next month. FatCat purchases the felt from an outside supplier, but the slate, legs and cue holder may either be manufactured by the company or purchased from an outside supplier. Manufacturing and purchase costs per unit are shown in the table below. Three departments are involved in the production of these components. The time (in minutes per unit) required to process each component in each department and the available monthly capacity (in hours) for the three departments are as follows. The management wants at least 25% of each component to be manufactured by FatCat. 1-) Formulate an LP model to minimize the cost of FatCat to satisfy the demand for pool tables. Clearly define all decision variables and constraints. 2-) Use OPL to solve your model. Attach the OPL file to your submission. a) How many of each component should be manufactured and how many should be purchased? b) What is the total cost of the manufacturing and purchasing plan? c) How many hours of production time are used in each department? 3-) Answer the following questions. Explain in detail. (Suppose that your computers are down after solving Question 2 so that you cannot solve a new problem from saratch (2) a) How much should Fatcat be willing to pay for an additional hour of time in the shaping department? b) Another manufacturer has offered to sell slates to FatCat for $42 each. Could FatCat improve its position by pursuing this opportunity? Why or why not

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts