Question: please solve this in excel and post the excel file or screenshot thanks The Alberta Chemical Company (ACC) makes two products, soap and shampoo, both

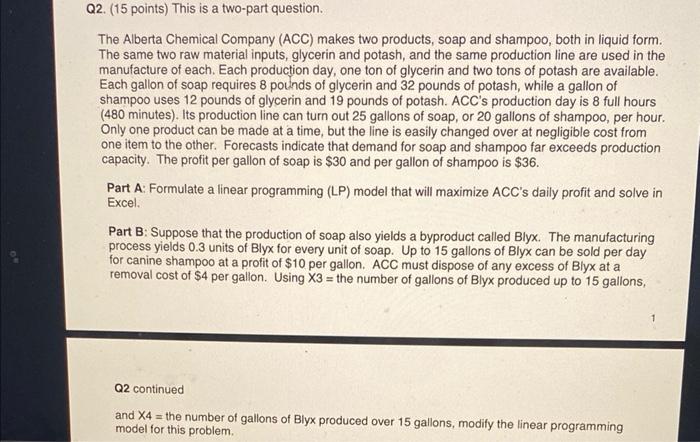

The Alberta Chemical Company (ACC) makes two products, soap and shampoo, both in liquid form. The same two raw material inputs, glycerin and potash, and the same production line are used in the manufacture of each. Each production day, one ton of glycerin and two tons of potash are available. Each gallon of soap requires 8 pounds of glycerin and 32 pounds of potash, while a gallon of shampoo uses 12 pounds of glycerin and 19 pounds of potash. ACC's production day is 8 full hours (480 minutes). Its production line can turn out 25 gallons of soap, or 20 gallons of shampoo, per hour. Only one product can be made at a time, but the line is easily changed over at negligible cost from one item to the other. Forecasts indicate that demand for soap and shampoo far exceeds production capacity. The profit per gallon of soap is $30 and per gallon of shampoo is $36. Part A: Formulate a linear programming (LP) model that will maximize ACC's daily profit and solve in Excel. Part B: Suppose that the production of soap also yields a byproduct called Blyx. The manufacturing process yields 0.3 units of Blyx for every unit of soap. Up to 15 gallons of Blyx can be sold per day for canine shampoo at a profit of $10 per gallon. ACC must dispose of any excess of Bly x at a removal cost of $4 per gallon. Using X3= the number of gallons of Blyx produced up to 15 gallons, Q2 continued and X4= the number of gallons of Blyx produced over 15 gallons, modify the linear programming model for this

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts