Question: please solve this in excel and show all the work. Life is besty and deciding how to the capital complicated Serie Neophy glad problems used

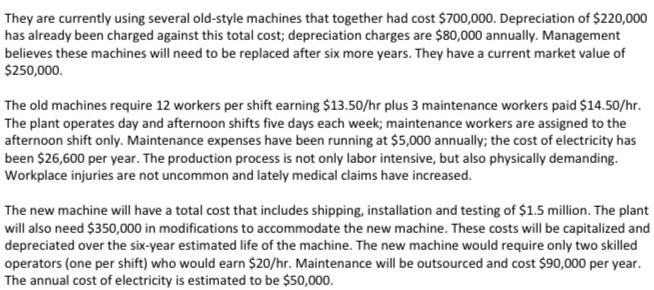

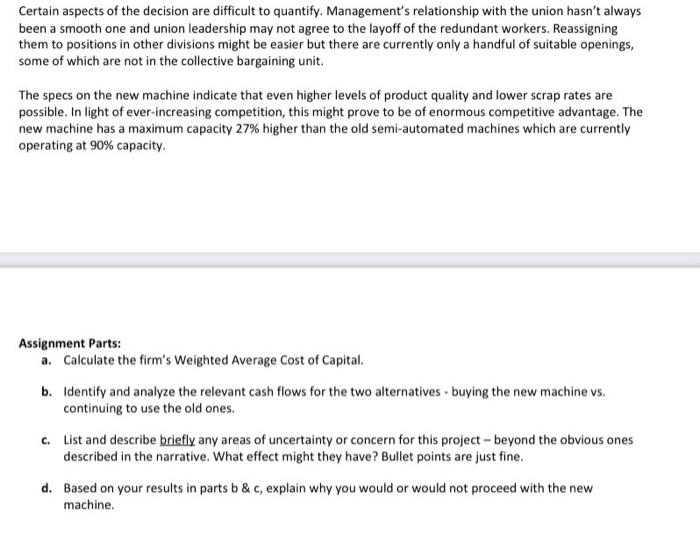

Life is besty and deciding how to the capital complicated Serie Neophy glad problems used in class and in the line angle homework thamore robust cap Budgeting decision problem Acne Marching worted to that has been in business for several eneration. It has ready and is now on the one with family members will owning wbal portion of these. Over the year compras redan to excepcional quality The fimm equity front share currently trate $3700 and do not pa dividend. Dette capitais provided by a single fondo year. 1.000 522.50 coupon $1.17. The Best 123. The traditional them for the rate has not been medewed in many war. Over the years, avholder how come to expect a tu. There corporate tax rate is 25. Trenuty securities are in the more monuitis 25 The Machine Tool Divonis considering the pude tomated, mobite production equipment. It around replace clear mahines and also ten mprovements in quality, and some ads Sinal pocity for experience of the magnitude of the presentar el estate of the projects its and bent nee They are currenting serat de machines that he had cost $70,000 Depreciation of $20,000 has already been charge this to a depreciation charges are 80.000 ray Management believes the chest and to be replaced her more. They have a current mariete $250.000 The old machines require worten permanence wortes paid $14.50 The planetes day and we donker wordt wemo only. Maintenance rates 5.000 the cost of electricity been 526.00 per year. The production processor. Dutie a comanding workplaceres et comment medicameve The new machine will have total cost that includes the taletion and testing of 15 million. The plant will words in modifications to the wheesecat be capital and deprecated over the rested ie the machine. The new machine would require only two killed operations for perdere SM500.000 pery The cost of election time to be 500.000 Certains of the deed he's relation with the win her always been the one to the off of the redundant workers tegning them to positions in other des might be one but there are only and stabile coming one of which are not in the secteur gegnt The speen the remain in the higher product and lower see pouble into evercompetition is prove to be amous comentage. The new machines 27 higher than the old son tomated machines which are current Alignment Parts Calculate the firm's Weighted Average Center Co. stand der Berconcerto pract beyond the violone described in the earth Watelet they were in & Based on your mus perts by would or would not proceed with the new Guidelines snow at work and briefel und nachimbe to stale with follow you wer-point of the Acme Manufacturing, Inc. was originally a family owned operation that has been in business for seweral generations. It has grown steadily and is now isted on the stock exchange with family members still wina substantial portion of the shares. Over the years, the company has acquired a reputation for exceptional quality and has won awards from major customers The fim i5S equity finance shares currently trade at $37.00 and do not pay a dividend Debt capitalis provided by a single issue of bonds (20 year. $1,000 par value, $82.50 annual coupon currently trading at 51.175. The frm's beta 125. Their traditional hurdle rate has been 12%, though the rate has not been reviewed in many years. Over the years, shareholders have come to expect a 10% return. Their corporate tax rate is 25%. Treasury securities are yielding 5.25%. The market rate of return on equities 9.23% The Machine Tool Division is considering the purchase of a piece of highly automated, robotic production ebuipment. I would replace older machines and would affer improvements in quality, and some additional capacity for expansion because of the magnitude of the proposed expenditure, a carefulestimate of the projects casts and benefits is needed They are currently using several old-style machines that together had cost $700,000 Depreciation of $220,000 has already been charged against this total cost depreciation charges are 580,000 annual Management believe the mainet will need to be replaced after the more years. They have a current market value of $250,000 The old machines requite 12 workers per shift earning S13.50/hr plus maintenance workers paid $14.50/h The plant operates day and afternoon shifts the days each week maintenance workers we assigned to the afternoon shift only. Maintenance expenses have been running at $5,000 armally the cost of electricity has been $25,500 per year. The production process is not only labor intensive, but also physically demanding. Workplace injuries are not uncommon and lately medical dams have increased The new machine will have a total cost that includes shipping Installation and testing of $15 million. The plant will also need $350,000 in modifications to accommodate the new machine. These costs will be capitalized and depreciated over the year estimated life of the machine. The new machine would require only two skilled operators (one per shit who would earn $20/h. Maintenance will be outsourced and cost $80,000 per your The annual cost of electricity is estmated to be $50,000 Certain aspects of the decision are difficult to quantity Management's relationship with the Union asn't always been a smooth one and union leadership may not agree to the layoff of the redundant workers. Reassgning them to positions in other divisions might be easier but there are currently only a handful of suitable openines, some of which are not in the collective bargaining unit, The specs on the new machine indicate that even higher levels of product quality and lower scrap rates are possible in tight of ever-increasing competition, this might prove to be of enormous competitive advantage. The new machine has a maximum capacity 27% higher than the old son-tomated machines which are currently Operating at o capacity Assignment Parts Calculate the firm's Weighted Average Cont of Capital identity and analyze the relevant cash flows for the two alternatives buying the new machine vs. continuing to use the old ones List and describe briefly any areas of uncertainty or concern for this project - beyond the obvious ones described in the narrative. What effect might they have? Bullet points are just fine. & Bined on your results in partabs &c, explain why you would or would not proceed with the new machine Guidelines Show all work and briefly label and explain each step. I must be able to follow your work - points off if I have to struggle with it Acme Manufacturing, Inc. was originally a family owned operation that has been in business for several generations. It has grown steadily and is now listed on the stock exchange with family members still owning a substantial portion of the shares. Over the years, the company has acquired a reputation for exceptional quality and has won awards from major customers. The firm is 55% equity financed; shares currently trade at $37.00 and do not pay a dividend. Debt capital is provided by a single issue of bonds (20 year, $1,000 par value, 582.50 annual coupon) currently trading at $1,175. The firm's beta is 1.25. Their traditional hurdle rate has been 12%, though the rate has not been reviewed in many years. Over the years, shareholders have come to expect a 10% return. Their corporate tax rate is 25%. Treasury securities are yielding 5.25%. The market rate of return on equities is 9.25%. The Machine Tool Division is considering the purchase of a piece of highly-automated, robotic production equipment. It would replace older machines and would offer improvements in quality, and some additional capacity for expansion. Because of the magnitude of the proposed expenditure, a careful estimate of the projects costs and benefits is needed. They are currently using several old-style machines that together had cost $700,000. Depreciation of S220,000 has already been charged against this total cost, depreciation charges are $80,000 annually. Management believes these machines will need to be replaced after six more years. They have a current market value of $250,000 The old machines require 12 workers per shift earning $13.50/hr plus 3 maintenance workers paid $14.50/hr. The plant operates day and afternoon shifts five days each week, maintenance workers are assigned to the afternoon shift only. Maintenance expenses have been running at $5,000 annually, the cost of electricity has been $26,600 per year. The production process is not only labor intensive, but also physically demanding Workplace injuries are not uncommon and lately medical claims have increased. The new machine will have a total cost that includes shipping installation and testing of $1.5 million. The plant will also need $350,000 in modifications to accommodate the new machine. These costs will be capitalized and depreciated over the six-year estimated life of the machine. The new machine would require only two skilled operators (one per shift) who would earn $20/hr. Maintenance will be outsourced and cost $90,000 per year. The annual cost of electricity is estimated to be $50,000 Certain aspects of the decision are difficult to quantify Management's relationship with the union hasn't always been a smooth one and union leadership may not agree to the layoff of the redundant workers. Reassigning them to positions in other divisions might be easier but there are currently only a handful of suitable openings, some of which are not in the collective bargaining unit. The specs on the new machine indicate that even higher levels of product quality and lower scrap rates are possible. In light of ever-increasing competition, this might prove to be of enormous competitive advantage. The new machine has a maximum capacity 27% higher than the old semi-automated machines which are currently operating at 90% capacity Assignment Parts: a. Calculate the firm's Weighted Average cost of Capital b. Identify and analyze the relevant cash flows for the two alternatives - buying the new machine vs. continuing to use the old ones. List and describe briefly any areas of uncertainty or concern for this project - beyond the obvious ones described in the narrative. What effect might they have? Bullet points are just fine. Acme Manufacturing, Inc. was originally a family owned operation that has been in business for several generations. It has grown steadily and is now listed on the stock exchange with family members still owning a substantial portion of the shares. Over the years, the company has acquired a reputation for exceptional quality and has won awards from major customers. The firm is 55% equity financed; shares currently trade at $37.00 and do not pay a dividend. Debt capital is provided by a single issue of bonds (20 year, $1,000 par value, $82.50 annual coupon) currently trading at $1,175. The firm's beta is 1.25. Their traditional hurdle rate has been 12%, though the rate has not been reviewed in many years. Over the years, shareholders have come to expect a 10% return. Their corporate tax rate is 25%. Treasury securities are yielding 5.25%. The market rate of return on equities is 9.25%. The Machine Tool Division is considering the purchase of a piece of highly-automated, robotic production equipment. It would replace older machines and would offer improvements in quality, and some additional capacity for expansion. Because of the magnitude of the proposed expenditure, a careful estimate of the projects costs and benefits is needed. They are currently using several old-style machines that together had cost $700,000. Depreciation of $220,000 has already been charged against this total cost; depreciation charges are $80,000 annually. Management believes these machines will need to be replaced after six more years. They have a current market value of $250,000. The old machines require 12 workers per shift earning $13.50/hr plus 3 maintenance workers paid $14.50/hr. The plant operates day and afternoon shifts five days each week; maintenance workers are assigned to the afternoon shift only. Maintenance expenses have been running at $5,000 annually; the cost of electricity has been $26,600 per year. The production process is not only labor intensive, but also physically demanding. Workplace injuries are not uncommon and lately medical claims have increased. The new machine will have a total cost that includes shipping, installation and testing of $1.5 million. The plant will also need $350,000 in modifications to accommodate the new machine. These costs will be capitalized and depreciated over the six-year estimated life of the machine. The new machine would require only two skilled operators (one per shift) who would earn $20/hr. Maintenance will be outsourced and cost $90,000 per year. The annual cost of electricity is estimated to be $50,000. Certain aspects of the decision are difficult to quantify. Management's relationship with the union hasn't always been a smooth one and union leadership may not agree to the layoff of the redundant workers. Reassigning them to positions in other divisions might be easier but there are currently only a handful of suitable openings, some of which are not in the collective bargaining unit. The specs on the new machine indicate that even higher levels of product quality and lower scrap rates are possible. In light of ever-increasing competition, this might prove to be of enormous competitive advantage. The new machine has a maximum capacity 27% higher than the old semi-automated machines which are currently operating at 90% capacity Assignment Parts: a. Calculate the firm's Weighted Average Cost of Capital. b. Identify and analyze the relevant cash flows for the two alternatives - buying the new machine vs. continuing to use the old ones. c. List and describe briefly any areas of uncertainty or concern for this project - beyond the obvious ones described in the narrative. What effect might they have? Bullet points are just fine. d. Based on your results in parts b&c, explain why you would or would not proceed with the new machine. Life is besty and deciding how to the capital complicated Serie Neophy glad problems used in class and in the line angle homework thamore robust cap Budgeting decision problem Acne Marching worted to that has been in business for several eneration. It has ready and is now on the one with family members will owning wbal portion of these. Over the year compras redan to excepcional quality The fimm equity front share currently trate $3700 and do not pa dividend. Dette capitais provided by a single fondo year. 1.000 522.50 coupon $1.17. The Best 123. The traditional them for the rate has not been medewed in many war. Over the years, avholder how come to expect a tu. There corporate tax rate is 25. Trenuty securities are in the more monuitis 25 The Machine Tool Divonis considering the pude tomated, mobite production equipment. It around replace clear mahines and also ten mprovements in quality, and some ads Sinal pocity for experience of the magnitude of the presentar el estate of the projects its and bent nee They are currenting serat de machines that he had cost $70,000 Depreciation of $20,000 has already been charge this to a depreciation charges are 80.000 ray Management believes the chest and to be replaced her more. They have a current mariete $250.000 The old machines require worten permanence wortes paid $14.50 The planetes day and we donker wordt wemo only. Maintenance rates 5.000 the cost of electricity been 526.00 per year. The production processor. Dutie a comanding workplaceres et comment medicameve The new machine will have total cost that includes the taletion and testing of 15 million. The plant will words in modifications to the wheesecat be capital and deprecated over the rested ie the machine. The new machine would require only two killed operations for perdere SM500.000 pery The cost of election time to be 500.000 Certains of the deed he's relation with the win her always been the one to the off of the redundant workers tegning them to positions in other des might be one but there are only and stabile coming one of which are not in the secteur gegnt The speen the remain in the higher product and lower see pouble into evercompetition is prove to be amous comentage. The new machines 27 higher than the old son tomated machines which are current Alignment Parts Calculate the firm's Weighted Average Center Co. stand der Berconcerto pract beyond the violone described in the earth Watelet they were in & Based on your mus perts by would or would not proceed with the new Guidelines snow at work and briefel und nachimbe to stale with follow you wer-point of the Acme Manufacturing, Inc. was originally a family owned operation that has been in business for seweral generations. It has grown steadily and is now isted on the stock exchange with family members still wina substantial portion of the shares. Over the years, the company has acquired a reputation for exceptional quality and has won awards from major customers The fim i5S equity finance shares currently trade at $37.00 and do not pay a dividend Debt capitalis provided by a single issue of bonds (20 year. $1,000 par value, $82.50 annual coupon currently trading at 51.175. The frm's beta 125. Their traditional hurdle rate has been 12%, though the rate has not been reviewed in many years. Over the years, shareholders have come to expect a 10% return. Their corporate tax rate is 25%. Treasury securities are yielding 5.25%. The market rate of return on equities 9.23% The Machine Tool Division is considering the purchase of a piece of highly automated, robotic production ebuipment. I would replace older machines and would affer improvements in quality, and some additional capacity for expansion because of the magnitude of the proposed expenditure, a carefulestimate of the projects casts and benefits is needed They are currently using several old-style machines that together had cost $700,000 Depreciation of $220,000 has already been charged against this total cost depreciation charges are 580,000 annual Management believe the mainet will need to be replaced after the more years. They have a current market value of $250,000 The old machines requite 12 workers per shift earning S13.50/hr plus maintenance workers paid $14.50/h The plant operates day and afternoon shifts the days each week maintenance workers we assigned to the afternoon shift only. Maintenance expenses have been running at $5,000 armally the cost of electricity has been $25,500 per year. The production process is not only labor intensive, but also physically demanding. Workplace injuries are not uncommon and lately medical dams have increased The new machine will have a total cost that includes shipping Installation and testing of $15 million. The plant will also need $350,000 in modifications to accommodate the new machine. These costs will be capitalized and depreciated over the year estimated life of the machine. The new machine would require only two skilled operators (one per shit who would earn $20/h. Maintenance will be outsourced and cost $80,000 per your The annual cost of electricity is estmated to be $50,000 Certain aspects of the decision are difficult to quantity Management's relationship with the Union asn't always been a smooth one and union leadership may not agree to the layoff of the redundant workers. Reassgning them to positions in other divisions might be easier but there are currently only a handful of suitable openines, some of which are not in the collective bargaining unit, The specs on the new machine indicate that even higher levels of product quality and lower scrap rates are possible in tight of ever-increasing competition, this might prove to be of enormous competitive advantage. The new machine has a maximum capacity 27% higher than the old son-tomated machines which are currently Operating at o capacity Assignment Parts Calculate the firm's Weighted Average Cont of Capital identity and analyze the relevant cash flows for the two alternatives buying the new machine vs. continuing to use the old ones List and describe briefly any areas of uncertainty or concern for this project - beyond the obvious ones described in the narrative. What effect might they have? Bullet points are just fine. & Bined on your results in partabs &c, explain why you would or would not proceed with the new machine Guidelines Show all work and briefly label and explain each step. I must be able to follow your work - points off if I have to struggle with it Acme Manufacturing, Inc. was originally a family owned operation that has been in business for several generations. It has grown steadily and is now listed on the stock exchange with family members still owning a substantial portion of the shares. Over the years, the company has acquired a reputation for exceptional quality and has won awards from major customers. The firm is 55% equity financed; shares currently trade at $37.00 and do not pay a dividend. Debt capital is provided by a single issue of bonds (20 year, $1,000 par value, 582.50 annual coupon) currently trading at $1,175. The firm's beta is 1.25. Their traditional hurdle rate has been 12%, though the rate has not been reviewed in many years. Over the years, shareholders have come to expect a 10% return. Their corporate tax rate is 25%. Treasury securities are yielding 5.25%. The market rate of return on equities is 9.25%. The Machine Tool Division is considering the purchase of a piece of highly-automated, robotic production equipment. It would replace older machines and would offer improvements in quality, and some additional capacity for expansion. Because of the magnitude of the proposed expenditure, a careful estimate of the projects costs and benefits is needed. They are currently using several old-style machines that together had cost $700,000. Depreciation of S220,000 has already been charged against this total cost, depreciation charges are $80,000 annually. Management believes these machines will need to be replaced after six more years. They have a current market value of $250,000 The old machines require 12 workers per shift earning $13.50/hr plus 3 maintenance workers paid $14.50/hr. The plant operates day and afternoon shifts five days each week, maintenance workers are assigned to the afternoon shift only. Maintenance expenses have been running at $5,000 annually, the cost of electricity has been $26,600 per year. The production process is not only labor intensive, but also physically demanding Workplace injuries are not uncommon and lately medical claims have increased. The new machine will have a total cost that includes shipping installation and testing of $1.5 million. The plant will also need $350,000 in modifications to accommodate the new machine. These costs will be capitalized and depreciated over the six-year estimated life of the machine. The new machine would require only two skilled operators (one per shift) who would earn $20/hr. Maintenance will be outsourced and cost $90,000 per year. The annual cost of electricity is estimated to be $50,000 Certain aspects of the decision are difficult to quantify Management's relationship with the union hasn't always been a smooth one and union leadership may not agree to the layoff of the redundant workers. Reassigning them to positions in other divisions might be easier but there are currently only a handful of suitable openings, some of which are not in the collective bargaining unit. The specs on the new machine indicate that even higher levels of product quality and lower scrap rates are possible. In light of ever-increasing competition, this might prove to be of enormous competitive advantage. The new machine has a maximum capacity 27% higher than the old semi-automated machines which are currently operating at 90% capacity Assignment Parts: a. Calculate the firm's Weighted Average cost of Capital b. Identify and analyze the relevant cash flows for the two alternatives - buying the new machine vs. continuing to use the old ones. List and describe briefly any areas of uncertainty or concern for this project - beyond the obvious ones described in the narrative. What effect might they have? Bullet points are just fine. Acme Manufacturing, Inc. was originally a family owned operation that has been in business for several generations. It has grown steadily and is now listed on the stock exchange with family members still owning a substantial portion of the shares. Over the years, the company has acquired a reputation for exceptional quality and has won awards from major customers. The firm is 55% equity financed; shares currently trade at $37.00 and do not pay a dividend. Debt capital is provided by a single issue of bonds (20 year, $1,000 par value, $82.50 annual coupon) currently trading at $1,175. The firm's beta is 1.25. Their traditional hurdle rate has been 12%, though the rate has not been reviewed in many years. Over the years, shareholders have come to expect a 10% return. Their corporate tax rate is 25%. Treasury securities are yielding 5.25%. The market rate of return on equities is 9.25%. The Machine Tool Division is considering the purchase of a piece of highly-automated, robotic production equipment. It would replace older machines and would offer improvements in quality, and some additional capacity for expansion. Because of the magnitude of the proposed expenditure, a careful estimate of the projects costs and benefits is needed. They are currently using several old-style machines that together had cost $700,000. Depreciation of $220,000 has already been charged against this total cost; depreciation charges are $80,000 annually. Management believes these machines will need to be replaced after six more years. They have a current market value of $250,000. The old machines require 12 workers per shift earning $13.50/hr plus 3 maintenance workers paid $14.50/hr. The plant operates day and afternoon shifts five days each week; maintenance workers are assigned to the afternoon shift only. Maintenance expenses have been running at $5,000 annually; the cost of electricity has been $26,600 per year. The production process is not only labor intensive, but also physically demanding. Workplace injuries are not uncommon and lately medical claims have increased. The new machine will have a total cost that includes shipping, installation and testing of $1.5 million. The plant will also need $350,000 in modifications to accommodate the new machine. These costs will be capitalized and depreciated over the six-year estimated life of the machine. The new machine would require only two skilled operators (one per shift) who would earn $20/hr. Maintenance will be outsourced and cost $90,000 per year. The annual cost of electricity is estimated to be $50,000. Certain aspects of the decision are difficult to quantify. Management's relationship with the union hasn't always been a smooth one and union leadership may not agree to the layoff of the redundant workers. Reassigning them to positions in other divisions might be easier but there are currently only a handful of suitable openings, some of which are not in the collective bargaining unit. The specs on the new machine indicate that even higher levels of product quality and lower scrap rates are possible. In light of ever-increasing competition, this might prove to be of enormous competitive advantage. The new machine has a maximum capacity 27% higher than the old semi-automated machines which are currently operating at 90% capacity Assignment Parts: a. Calculate the firm's Weighted Average Cost of Capital. b. Identify and analyze the relevant cash flows for the two alternatives - buying the new machine vs. continuing to use the old ones. c. List and describe briefly any areas of uncertainty or concern for this project - beyond the obvious ones described in the narrative. What effect might they have? Bullet points are just fine. d. Based on your results in parts b&c, explain why you would or would not proceed with the new machine

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts