Question: Please solve this Linear Program using CPLEX. Steelco Inc. Steelco Inc. manufactures I, W, U, H, and L beams. You are required to help Steelco

Please solve this Linear Program using CPLEX.

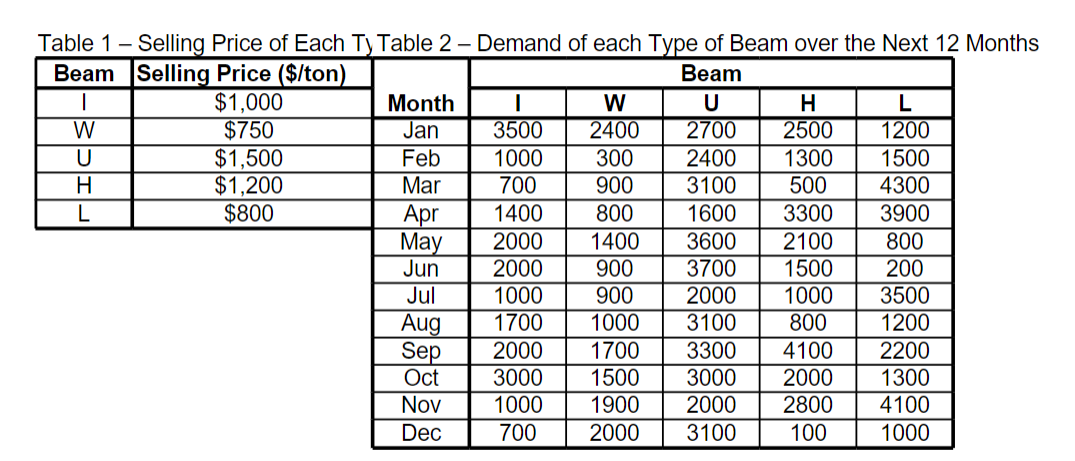

Steelco Inc. Steelco Inc. manufactures I, W, U, H, and L beams. You are required to help Steelco develop an optimized work schedule for the 12 months of 2020. This year, under a similar demand and without any optimization tools, the company expects to clear around $60,000,000 in profits from these five products. To manufacture beams, Steelco purchases recycled steel for $400/ton and new steel for $600/ton. Due to the quality of the steel, only 80% of the recycled steel can be used to produce the products. Furthermore, at most 6,000 tons of recycled steel can be purchased each month and only 5,000 tons of new steel can be purchased at any month. Each ton of I, W, U, H, and L beams that is produced is sold by the price described in Table 1 (see file Data Set - Steelco.xlsx in Canvas). Due to quality requirements, at least 40%, 20%, 60%, 10%, and 25% of I, W, U, H, and L beams, respectively, must be manufactured from new steel. Each ton of product held over in inventory from one month to the next month costs the company $40/ton. If demand at each month is not met, then there is a penalty cost of $100/ton for I beams, $300/ton for W beams, $250/tons for U beams, $600/ton for H beams, and $1000/ton for L beams. In such a case, the item is placed on backorder and the order must be shipped to the customer at some future time. Demand of each product over the next 12 months is shown in Table 2 (see file Data Set - Steelco.xlsx in Canvas). You must assume that you have nothing in inventory or items that are backordered, and that you must end at the end of Dec. 2020 with the same condition. L U 14001 Table 1 - Selling Price of Each Ty Table 2-Demand of each Type of Beam over the Next 12 Months Beam Selling Price ($/ton) Beam $1,000 Month I W UTH W $750 Jan 3500 2400 2700 25001200 $1,500 Feb 1000 300 2400 1300 1500 H $1,200 Mar 700 900 3100 500 4300 L $800 Apr 800 1600 3300 3900 May 2000 1400 3600 2100 800 Jun 2000 900 3700 1500 200 Jul 1000 900 2000 1000 3500 Aug 1700 1000 3100800 1200 Sep 2000 1700 3300 4100 2200 Oct 3000 1500 3000 2000 1300 1000 1900 2000 2800 4100 Dec 700 2000 3100 100 1000 Steelco Inc. Steelco Inc. manufactures I, W, U, H, and L beams. You are required to help Steelco develop an optimized work schedule for the 12 months of 2020. This year, under a similar demand and without any optimization tools, the company expects to clear around $60,000,000 in profits from these five products. To manufacture beams, Steelco purchases recycled steel for $400/ton and new steel for $600/ton. Due to the quality of the steel, only 80% of the recycled steel can be used to produce the products. Furthermore, at most 6,000 tons of recycled steel can be purchased each month and only 5,000 tons of new steel can be purchased at any month. Each ton of I, W, U, H, and L beams that is produced is sold by the price described in Table 1 (see file Data Set - Steelco.xlsx in Canvas). Due to quality requirements, at least 40%, 20%, 60%, 10%, and 25% of I, W, U, H, and L beams, respectively, must be manufactured from new steel. Each ton of product held over in inventory from one month to the next month costs the company $40/ton. If demand at each month is not met, then there is a penalty cost of $100/ton for I beams, $300/ton for W beams, $250/tons for U beams, $600/ton for H beams, and $1000/ton for L beams. In such a case, the item is placed on backorder and the order must be shipped to the customer at some future time. Demand of each product over the next 12 months is shown in Table 2 (see file Data Set - Steelco.xlsx in Canvas). You must assume that you have nothing in inventory or items that are backordered, and that you must end at the end of Dec. 2020 with the same condition. L U 14001 Table 1 - Selling Price of Each Ty Table 2-Demand of each Type of Beam over the Next 12 Months Beam Selling Price ($/ton) Beam $1,000 Month I W UTH W $750 Jan 3500 2400 2700 25001200 $1,500 Feb 1000 300 2400 1300 1500 H $1,200 Mar 700 900 3100 500 4300 L $800 Apr 800 1600 3300 3900 May 2000 1400 3600 2100 800 Jun 2000 900 3700 1500 200 Jul 1000 900 2000 1000 3500 Aug 1700 1000 3100800 1200 Sep 2000 1700 3300 4100 2200 Oct 3000 1500 3000 2000 1300 1000 1900 2000 2800 4100 Dec 700 2000 3100 100 1000

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts