Question: Please solve this problem. A thumb up will be guaranteed. Please do not copy and paste answers from similar questions or a thumb down will

Please solve this problem. A thumb up will be guaranteed.

Please do not copy and paste answers from similar questions or a thumb down will be given.

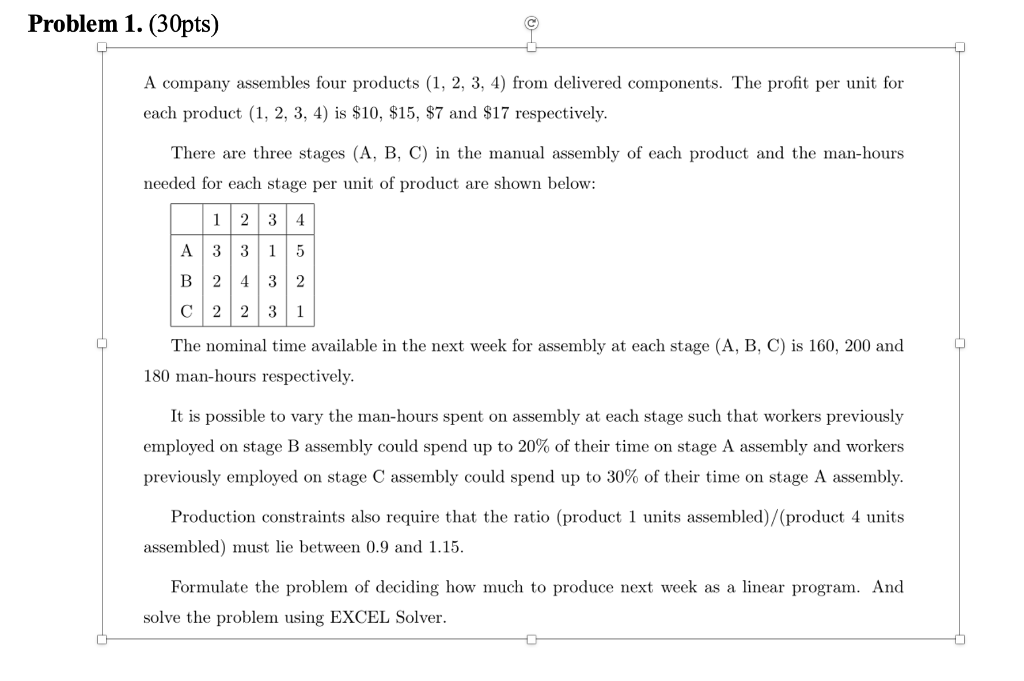

Problem 1. (30pts) A company assembles four products (1, 2, 3, 4) from delivered components. The profit per unit for each product (1, 2, 3, 4) is $10, $15, $7 and $17 respectively. There are three stages (A, B, C) in the manual assembly of each product and the man-hours needed for each stage per unit of product are shown below: 1 2 3 4 A 3 3 1 5 B 2 4 3 2 C 2 2 3 1 The nominal time available in the next week for assembly at each stage (A, B, C) is 160, 200 and 180 man-hours respectively. It is possible to vary the man-hours spent on assembly at each stage such that workers previously employed on stage B assembly could spend up to 20% of their time on stage A assembly and workers previously employed on stage C assembly could spend up to 30% of their time on stage A assembly. Production constraints also require that the ratio (product 1 units assembled)/(product 4 units assembled) must lie between 0.9 and 1.15. Formulate the problem of deciding how much to produce next week as a linear program. And solve the problem using EXCEL Solver

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts