Question: ***PLEASE SOLVE WITHOUT EXCEL. JUST HAND WRITING*** ****Please show all steps clearly. If you cannot solve it please don't write anything PLEASE.**** ******PLEASE DO NOT

***PLEASE SOLVE WITHOUT EXCEL. JUST HAND WRITING***

****Please show all steps clearly. If you cannot solve it please don't write anything PLEASE.****

******PLEASE DO NOT COPY PASTE FROM OTHER SOLUTIONS. THESE ARE NOT CLEAR FOR ME.*****

***PLEASE SOLVE WITHOUT EXCEL. JUST HAND WRITING***

****Please show all steps clearly. If you cannot solve it please don't write anything PLEASE.****

******PLEASE DO NOT COPY PASTE FROM OTHER SOLUTIONS. THESE ARE NOT CLEAR FOR ME.*****

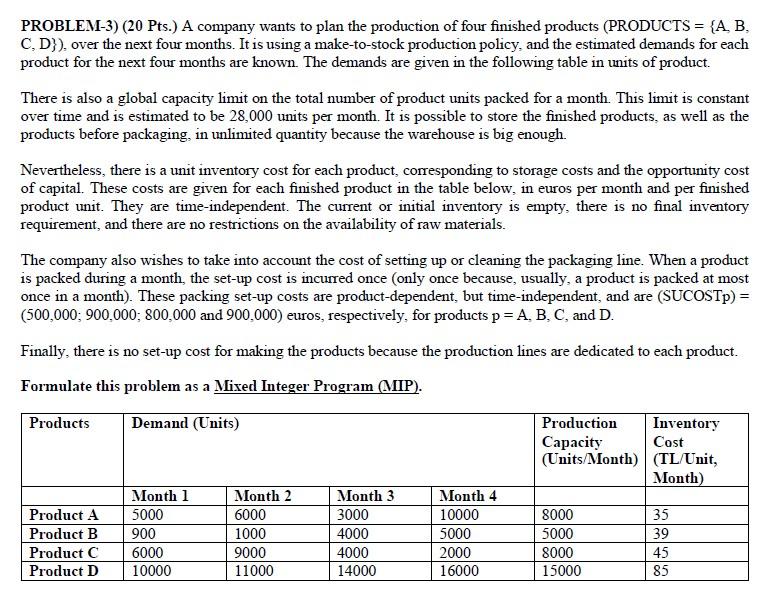

PROBLEM-3) (20 Pts.) A company wants to plan the production of four finished products (PRODUCTS = {A, B. C, D}), over the next four months. It is using a make-to-stock production policy, and the estimated demands for each product for the next four months are known. The demands are given in the following table in units of product. There is also a global capacity limit on the total number of product units packed for a month. This limit is constant over time and is estimated to be 28,000 units per month. It is possible to store the finished products, as well as the products before packaging, in unlimited quantity because the warehouse is big enough. Nevertheless, there is a unit inventory cost for each product, corresponding to storage costs and the opportunity cost of capital. These costs are given for each finished product in the table below, in euros per month and per finished product unit. They are time-independent. The current or initial inventory is empty, there is no final inventory requirement, and there are no restrictions on the availability of raw materials. The company also wishes to take into account the cost of setting up or cleaning the packaging line. When a product is packed during a month, the set-up cost is incurred once (only once because, usually, a product is packed at most once in a month). These packing set-up costs are product-dependent, but time-independent, and are (SUCOSTp) = (500,000; 900,000; 800,000 and 900,000) euros, respectively, for products p = A. B, C, and D. Finally, there is no set-up cost for making the products because the production lines are dedicated to each product. Formulate this problem as a Mixed Integer Program (MIP). Products Demand (Units) Production Inventory Cost Capacity (Units/Month) (TL/Unit, Month) Month 1 Month 2 Month 3 Product A 5000 6000 3000 8000 35 Product B 900 1000 4000 5000 39 Product C 6000 9000 4000 8000 45 Product D 10000 11000 14000 15000 85 Month 4 10000 5000 2000 16000

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts