Question: Please to use the case below to answer the following questions thoroughly. 1)Determine and state the major issue/ issues 2)Suggest options which could possibly lead

Please to use the case below to answer the following questions thoroughly.

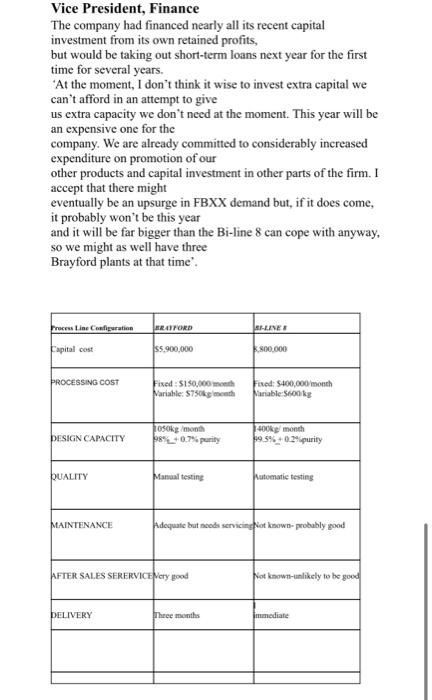

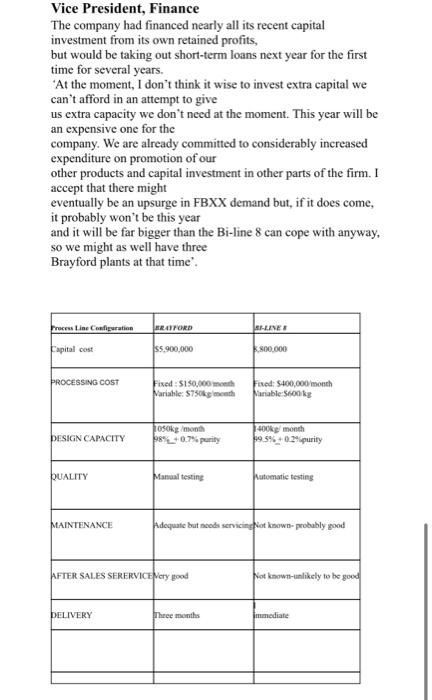

Freeman Biotest Inc CASE 2 Freeman Biotest was one of the largest independent companies supplying the food processing industry. Its initial success had come with a food preservative, used mainly for meat-based products and marketed under the name of "FBXX'. Other products were subsequently developed in the food colouring and food container coating fields, so that now FBXX accounted for only 25 per cent of total company sales, which now were slightly over $100 million. The decision The problem over which there was such controversy related to the replacement of one of the process lines used to manufacture FBXX. Currently two such process lines were used, both had been designed and installed by Brayford Corp., a process equipment manufacturer. It was the older of the two Brayford lines which was giving trouble. High breakdown figures, with erratic quality levels, meant that output level requirements were only just being reached. The problem was: should the company replace the ageing Brayford line with a new Brayford line, or should it commission another process line, the "Bi-line 8'line, which would be manufactured by a relatively new company, Bi-Line Inc. VP for Technology had drawn up a comparison of the two units, shown in Table 4.7. The body considering the problem was the newly formed Management Committee. The committee consisted of the VP for Technology and the Marketing VP who had been with the firm since its beginning, together with the VPs for Operations and Finance, both of whom had joined the company only six months before. What follows is a condensed version of the information presented by each manager to the committee, together with their attitudes to the decision. VP, Marketing Currently the market for this type of preservative had reached a size of some $50 million, of which Freeman Biotest supplied approximately 48 per cent. There had, of late, been significant changes in the market - in particular many of the users of preservatives were now able to buy products similar to FBXX. The result had been the evolution of a much more price-sensitive market than had previously been the case. Further market projections were somewhat uncertain. It was clear that the total market would not shrink (in volume terms) and best estimates suggested a market of perhaps $60 million within the next three or four years (at current prices). Although the food preservative market had advanced by a series of technical innovations, 'real' changes in the basic product were now few and far between. FBXX was sold in either solid powder or liquid form, depending on the particular needs of the customer. Prices tended to be related to the weight of chemical used, however. Thus, for example, currently the average market price was approximately $1,050 per kg. There were, of course, wide variations depending on order size, etc. 'At the moment I am mainly interested in getting the right quantity and quality of FBXX each month. I'm worried that unless we get a reliable new process line quickly, we will have problems. The Bi-line 8 line could be working in a few weeks, giving better quality too. Furthermore, if demand does increase, the Bi-line 8 will give us the extra capacity'. The Vice President for Technology The major part of the VP for Technology's budget was devoted to modifying basic FBXX so that it could be used for more acidic food products such as fruit. This was not proving easy and as yet nothing had come of the research, although the Chief Chemist remained optimistic. If we succeed in modifying FBXX, the market opportunities will be doubled overnight and we will need the extra capacity. I know we would be taking a risk by going for the Bi-line 8 machine, but our company has grown by gambling on our research findings, and we must continue to show faith. Also the Bi-line 8 technology uses principles which will be in all similar technologies in the future. We have to start learning how to exploit them sooner or later'. Vice President, Operations The FBXX Division was self-contained as a production unit, located at the smaller of the company's two sites. Production requirements for FBXX were currently at a steady rate of around 1900 kg per month. The technicians who staffed the FBXX lines were the only technicians in Freeman Biotest who did all their own minor repairs and full quality control. The reason for this was largely historical, since when the firm started, the product was experimental and qualified technicians were needed to operate the plant. Four of the six had been with the firm almost from its beginning It's all right for some of my colleagues to talk about a big expansion of FBXX sales; they don't have to cope with all the problems if it doesn't happen. The fixed costs of the Bi-line 8 unit are nearly three times those of the Brayford. Just think what that will do to my budget at low volumes of output. As I understand it, there is absolutely no evidence to show a large upswing in FBXX. No, the whole idea (of the Bi-line 8 plant) is just too risky. Not only is there the risk. I don't think it is generally understood what the consequences of the Bi-line 8 would mean. We would need twice the variety of spares for a start. But what really worries me is the staff's reaction. As fully qualified technicians they regard themselves as the elite of the firm; so they should, they are paid practically the same as I am! If we get the Bi-line 8 plant all their most interesting work, like the testing and the maintenance, will disappear or be greatly reduced. They will finish up as highly paid process workers'. Vice President, Finance The company had financed nearly all its recent capital investment from its own retained profits, but would be taking out short-term loans next year for the first time for several years. 'At the moment, I don't think it wise to invest extra capital we can't afford in an attempt to give us extra capacity we don't need at the moment. This year will be an expensive one for the company. We are already committed to considerably increased expenditure on promotion of our other products and capital investment in other parts of the firm. I accept that there might eventually be an upsurge in FBXX demand but, if it does come, it probably won't be this year and it will be far bigger than the Bi-line 8 can cope with anyway. so we might as well have three Brayford plants at that time". Process Line Configuration Capital cost PROCESSING COST DESIGN CAPACITY QUALITY MAINTENANCE BRATFORD DELIVERY $5,900,000 Fixed: $150,000 month Variable: $750kg month 1050kg/month 98%+0.7% purity Manual testing AFTER SALES SERERVICE Very good S-LINE & Three months .800,000 Fixed: $400,000/month Nariable:$600 kg 400kg/month 99.5%+0.2%purity Adequate but needs servicingNot known-probably good Automatic testing Not known-unlikely to be good immediate

1)Determine and state the major issue/ issues

2)Suggest options which could possibly lead to a solution/amelioration of the stated issues.

3) Recommendations and the rationale from options as per the case.

4)Recommendations and their rationale outside of the ambit of the information given above. It is expected that in this section the student will impose his knowledge of the subject on devising solutions which were not already proposed or implied within the case.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock