Question: Please type the answer by computer, so i can see it clearly, thank you!!! GIANT is a bicycle manufacturer that offers its products to stores

Please type the answer by computer, so i can see it clearly, thank you!!!

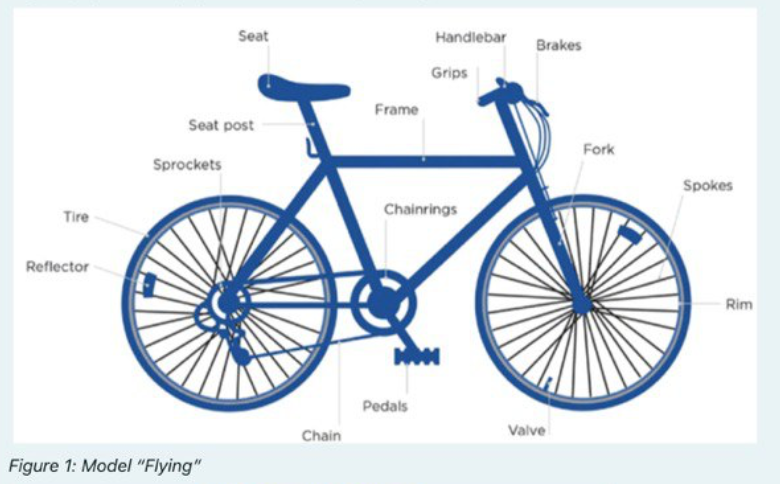

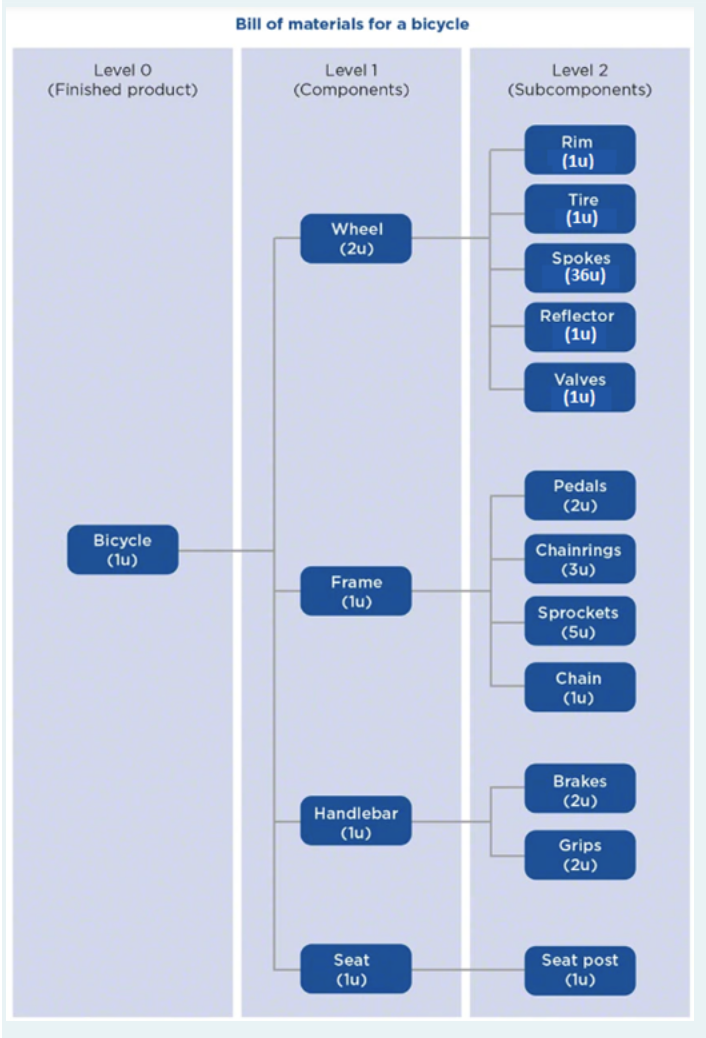

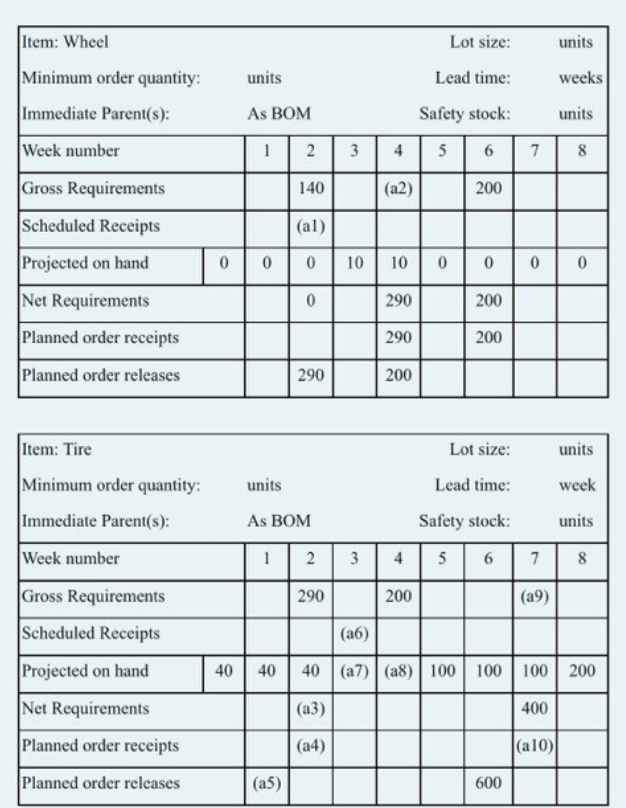

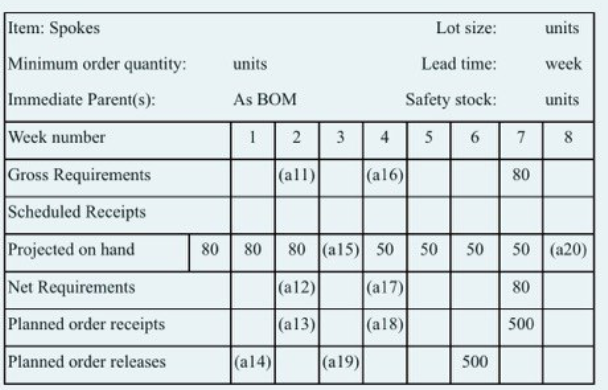

GIANT is a bicycle manufacturer that offers its products to stores in China and Hong Kong. One of the most popular bicycle models is "Flying" (Figure 1), which is built according to the bill of materials (BOM) diagram (Figure 2) shown below. The quantity is also displayed at each component, as seen below. Wheel (2u) denotes that two units are required to produce one bicycle (1u), while Tire (1u) denotes that one unit is required to produce one wheel.

Figure 2: BOM of model Flying

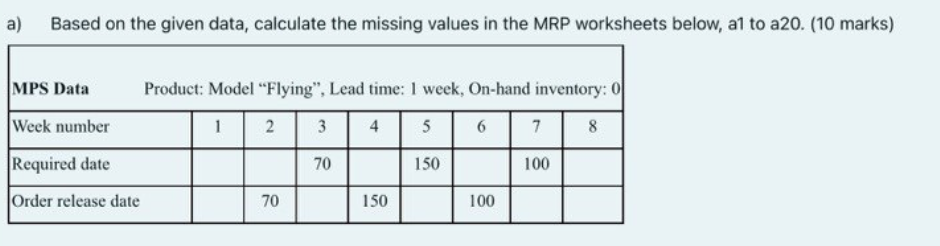

70 units of model Flying are needed in week 3, 150 units in week 5, and 100 units in week 7. The lead time for assembly of Model Flying is one week and there is no on-hand inventory.

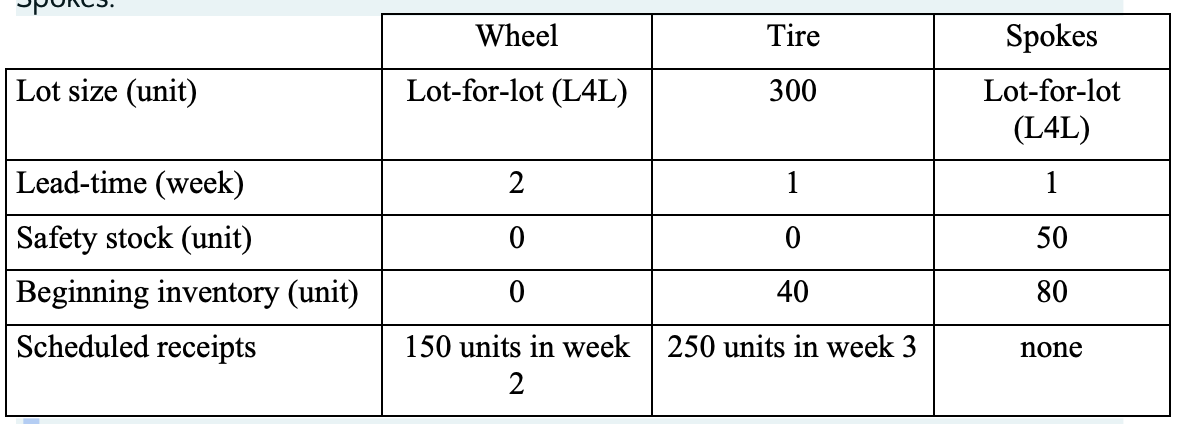

Additional information regarding the major components Wheel, Tire, and Spokes can be found in the table below.

Tires are sold to a retailer who requires 500 units in week 7, while for Spokes are also sold to a retailer who requires 50 units in week 2, 100 units in week 4 and 80 units in week 7. The minimum production quantity of Spokes is 500 units.

Question:

1(b)

Calculate the total expenses (consider the setup cost + holding cost only) of Wheel, Tire, and Spokes based on the projected order released and inventory level (referred to as Projected on Hand) over an 8-week period if the Holding cost is $2/unit/week and the Setup cost is $400. Your holding cost calculation should exclude the first week's inventory units.

Because of bad economic environment under COVID-19, the retailer has asked GIANT for discounts on the price of model Flying. After negotiation, GIANT offered the following discount schedule for the retailer:

| Quantity ordered per order | Discount on unit price |

| Less than 120 units | 0% |

| 120 199 units | 10% |

| 200 units or above | 20% |

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts