Question: Please use excel to answer and the formulas to get the values CASE STUDY Kloss Planters and Harvesters Kevin Cho, general manager at Kloss Planters

Please use excel to answer and the formulas to get the values

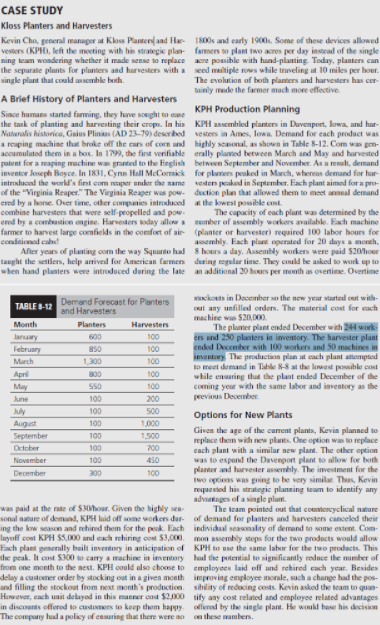

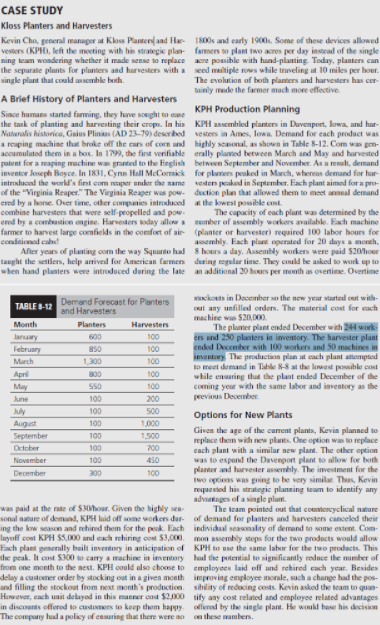

CASE STUDY Kloss Planters and Harvesters Kevin Cho, general manager at Kloss Planters and Hare 1800s and early 1900s. Some of these devices allowed vesters (KPD), left the meeting with his strategic plan- farmers to plant two acres per day instead of the single ning team wondering whether it made sense to replace are possible with hand-planting. Today, planters can the separate plants for planters and harvesters with a seed multiple rows while in veling at 10 miles per hour. single plant that could assemble both The evolution of both planters and harvesters hascer tainly made the farmer much more effective A Brief History of Planters and Harvesters Since humans started farming, they have sought to use KPH Production Planning the task of planting and harvesting their crops. In his KPH assembled planters in Duvemport, low, and har Naturalis historica, Gaius Plinis (AD 23-79) described resters in Ames, lowa. Demand for each product was a reaping machine that broke off the cars of corn and highly seasonal, as shown in Table 8-12. Com was gen- accumulated them in a box. In 1799, the first verifiable enally planted between March and May and harvested patent for a reaping machine was granted to the faglish between September and November. As a result, demand inventor Joseph Boyce. In 1831. Cyrus Hall McCork for plantes peaked in March, whereas demand for har introduced the world's fint com per under the same vesterpaked in September. Each plant aimed for a pro- of the Virginia Reaper." The Virginia Reaper was pow. duction plan that allowed them to meet al dentand ered by a horse. Over time, other companies introduced at the lowest possible cost. combine harvesters that were self-propelled and pow. The capacity of cach plant was determined by the ered by a combustion engine. Harvesters today allow a number of assembly workers available. Each machine farmer to harvest large comfields in the comfort of air planter or harvester) required 100 labor hours for conditioned caha! sembly. Each plant operated for 20 days a month, After years of plasting com the way Squanto ad 8 hours a day. Assembly workers were paid $20/hour taught the settlers, help arrived for American farmers during regular time. They could be asked to work up to when and planters were introduced during the late an additional 20 hours per month as overtime. Overtime TABLE 8-12 Demand Forecast for Planters ockouts in December so the new year started out with and Harvesters ut any unfilled orders. The material cost for each machine was $20,000 Month Planters Harvesters The planter plantended December with 2 work January 600 100 ers and 250 planters in inventory. The harvester plant February 850 100 ended December with 100 workers and 50 machines in March 1300 100 inventory. The production plan at each plant attempted to meet demand in Table 8-8 at the lowest possible cost April 800 100 while ensuring that the plant ended December of the May 550 100 coming your with the same labor and investory as the June 100 200 previous December July 100 500 Options for New Plants August 100 1.000 September 100 Given the age of the current plants, Kevin planned to 1.500 replace them with new plants. One option was to replace October 100 700 each plant with a similar new plant. The other option November 100 450 was to expand the Davenport plant to allow for both December 300 100 planter and harvester assembly. The investment for the Two piens was going to be very similar Thus, Kevin requested his strategic planning team to identify any advantages of a single plant was paid at the rate of 30 hour. Given the highly sea The team pointed out that countercyclical nature sonal nature of demand, KPH Inidoff some workers dur- of demand for planters and harvesters canceled their ing the low season and rehired them for the peak. Each individual seasonality of demand to some extent. Com layoff cost KPH $5,000 and each rehiring cost $3,000, mon assembly steps for the two products would allow Fach plant generally built inventory in anticipation of KPH to use the same labor for the two products. This the peak. It cost $300 to carry a machine in inventory to the potential to significantly reduce the number of from one month to the best. KPH could also choose to employees laid off and retired each year. Besides delay a customer order by stocking out in a given month improving employee morale, such a change had the pos- and filling the stockout from next month's productionsibility of reducing costs. Kevin asked the team to quan However, each unit delayed in this marron $2.000 tify any cost related and employee related advantages in discounts offered to customers to keep them happy ofered by the single plan. He would have his decision The company had a policy of ensuring that there were no ce these numbers