Question: please use this reference: Introduction to Materials Management by J.R. Tony Arnold, S. N. Chapman, Lloyd M.C., Sixth Edition, 2008 Prepare a comprehensive materials requirement

please use this reference:

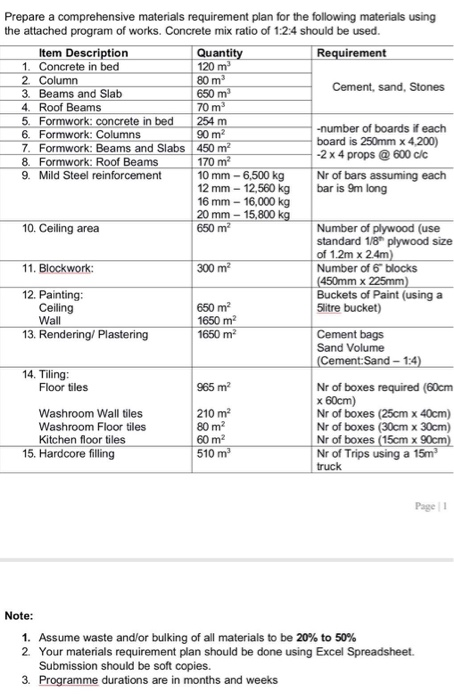

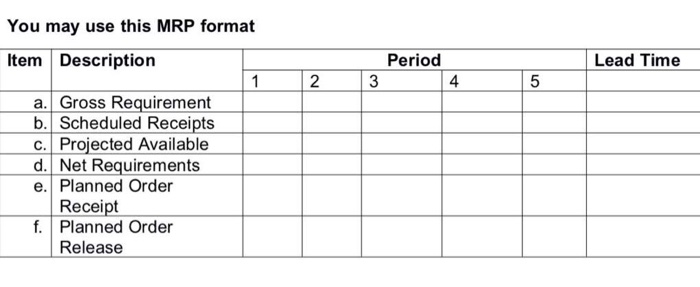

Prepare a comprehensive materials requirement plan for the following materials using the attached program of works. Concrete mix ratio of 1:2:4 should be used. Item Description Quantity Requirement 1. Concrete in bed 120 m 2 Column 80 m Cement, sand, Stones 3. Beams and Slab 650 m 4. Roof Beams 70 m 5. Formwork: concrete in bed 254 m 6. Formwork: Columns -number of boards if each 90 m board is 250mm x 4.200) 7. Formwork: Beams and Slabs 450 m 2 x 4 props @ 600 cc 8. Formwork: Roof Beams 170 m 9. Mild Steel reinforcement 10 mm -6,500 kg Nr of bars assuming each 12 mm - 12,560 kg bar is 9m long 16 mm - 16,000 kg 20 mm - 15,800 kg 10. Ceiling area 650 m Number of plywood (use standard 1/8" plywood size of 1.2m x 2.4m) 11. Blockwork: 300 m Number of 6 blocks (450mm x 225mm) 12. Painting: Buckets of Paint (using a Ceiling 650 m 5litre bucket) Wall 1650 m 13. Rendering/ Plastering 1650 m Cement bags Sand Volume (Cement:Sand - 1:4) 14. Tiling: Floor tiles 965 m Nr of boxes required (60cm x 60cm) Washroom Wall tiles 210 m Nr of boxes (25cm x 40cm) Washroom Floor tiles 80 m2 Nr of boxes (30cm x 30cm) Kitchen floor tiles 60 m2 Nr of boxes (15cm x 90cm) 15. Hardcore filling 510 m Nr of Trips using a 15m truck Page 1 Note: 1. Assume waste and/or bulking of all materials to be 20% to 50% 2. Your materials requirement plan should be done using Excel Spreadsheet. Submission should be soft copies. 3. Programme durations are in months and weeks You may use this MRP format Item Description Period Lead Time 1 3 4 5 N a. Gross Requirement b. Scheduled Receipts c. Projected Available d. Net Requirements e. Planned Order Receipt f. Planned Order Release Prepare a comprehensive materials requirement plan for the following materials using the attached program of works. Concrete mix ratio of 1:2:4 should be used. Item Description Quantity Requirement 1. Concrete in bed 120 m 2 Column 80 m Cement, sand, Stones 3. Beams and Slab 650 m 4. Roof Beams 70 m 5. Formwork: concrete in bed 254 m 6. Formwork: Columns -number of boards if each 90 m board is 250mm x 4.200) 7. Formwork: Beams and Slabs 450 m 2 x 4 props @ 600 cc 8. Formwork: Roof Beams 170 m 9. Mild Steel reinforcement 10 mm -6,500 kg Nr of bars assuming each 12 mm - 12,560 kg bar is 9m long 16 mm - 16,000 kg 20 mm - 15,800 kg 10. Ceiling area 650 m Number of plywood (use standard 1/8" plywood size of 1.2m x 2.4m) 11. Blockwork: 300 m Number of 6 blocks (450mm x 225mm) 12. Painting: Buckets of Paint (using a Ceiling 650 m 5litre bucket) Wall 1650 m 13. Rendering/ Plastering 1650 m Cement bags Sand Volume (Cement:Sand - 1:4) 14. Tiling: Floor tiles 965 m Nr of boxes required (60cm x 60cm) Washroom Wall tiles 210 m Nr of boxes (25cm x 40cm) Washroom Floor tiles 80 m2 Nr of boxes (30cm x 30cm) Kitchen floor tiles 60 m2 Nr of boxes (15cm x 90cm) 15. Hardcore filling 510 m Nr of Trips using a 15m truck Page 1 Note: 1. Assume waste and/or bulking of all materials to be 20% to 50% 2. Your materials requirement plan should be done using Excel Spreadsheet. Submission should be soft copies. 3. Programme durations are in months and weeks You may use this MRP format Item Description Period Lead Time 1 3 4 5 N a. Gross Requirement b. Scheduled Receipts c. Projected Available d. Net Requirements e. Planned Order Receipt f. Planned Order Release Introduction to Materials Management by J.R. Tony Arnold, S. N. Chapman, Lloyd M.C., Sixth Edition, 2008

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock