Question: please work out task 3 and 4 with full working out. Fenton Ltd Fenton Ltd is a manufacturing organisation supplying specialised engineered products to a

please work out task 3 and 4 with full working out.

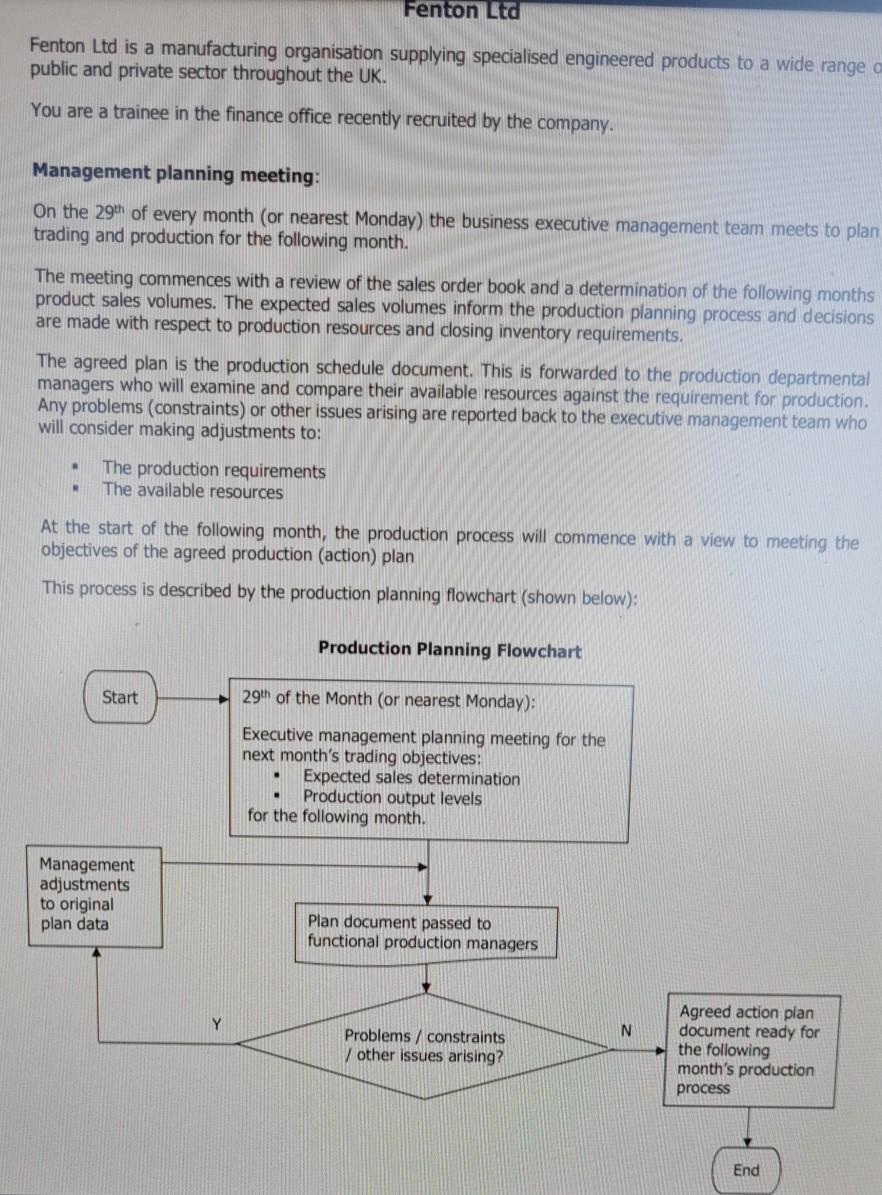

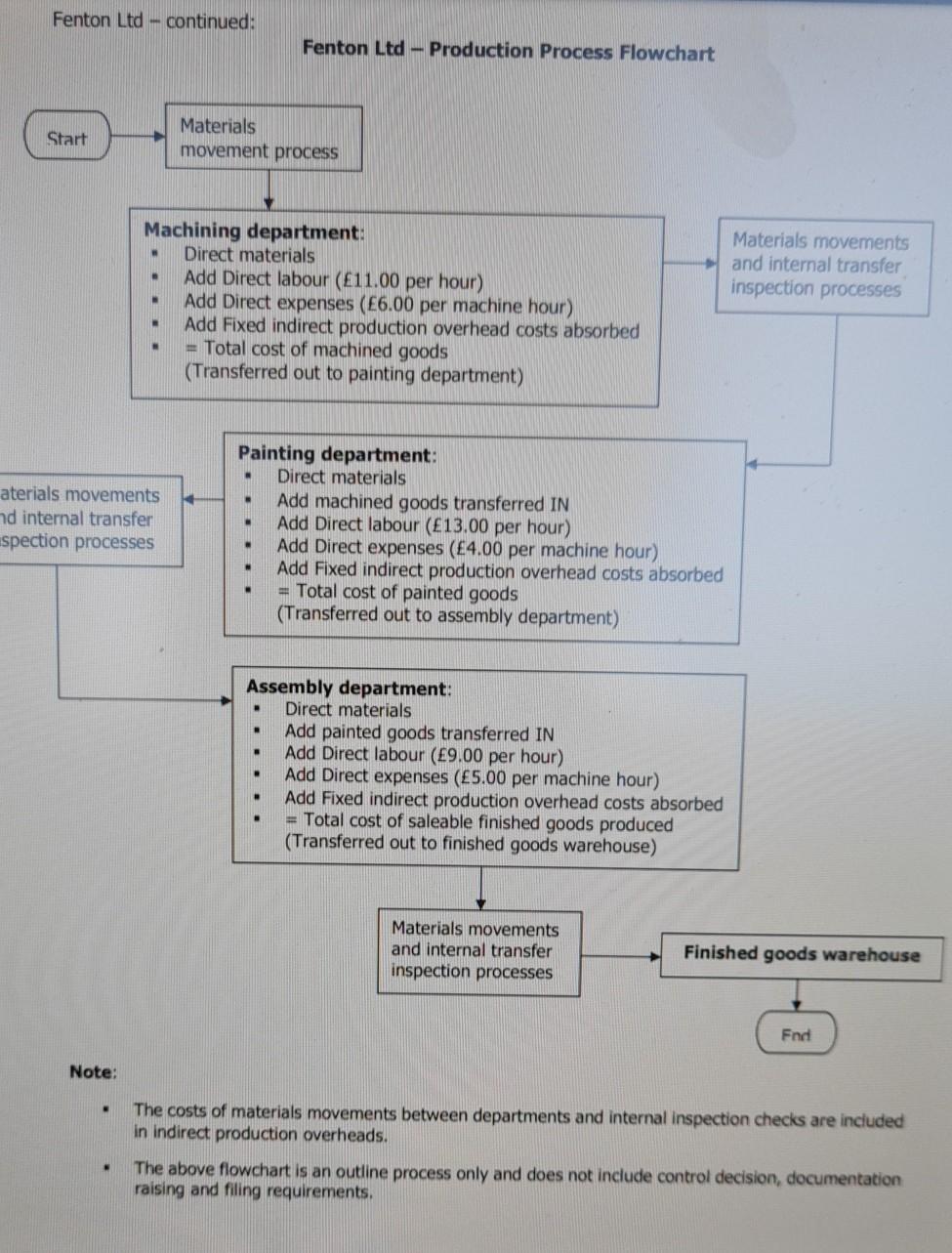

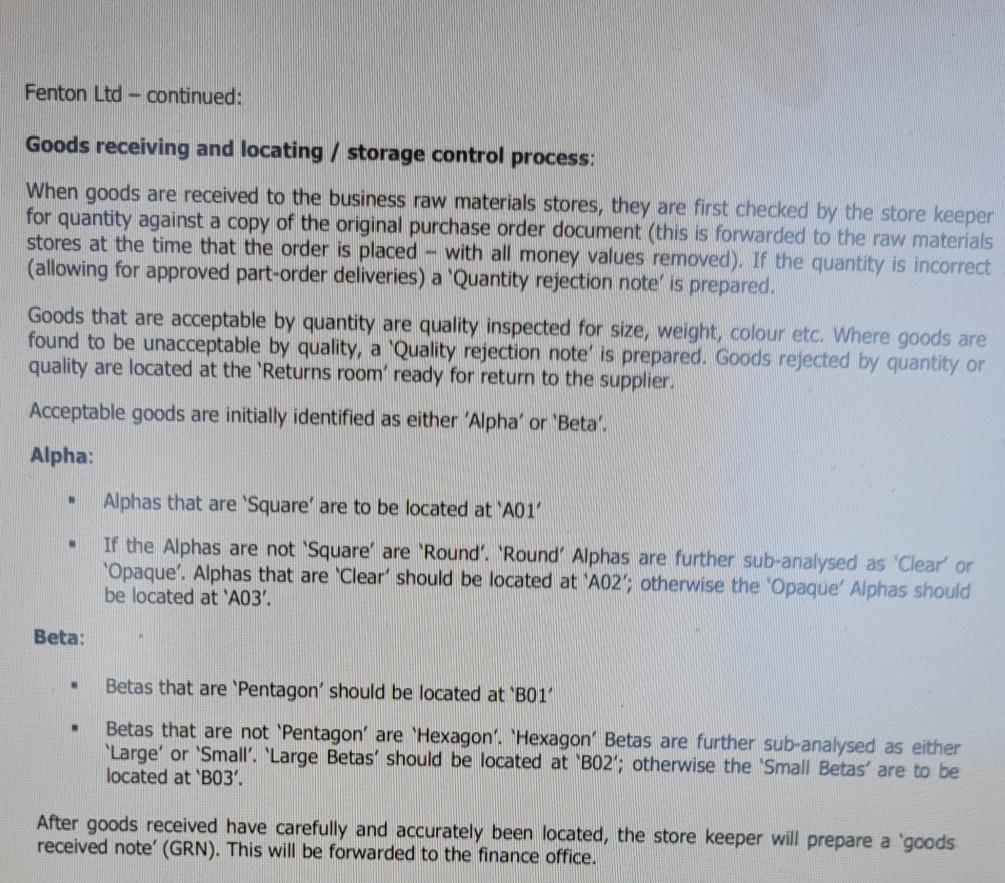

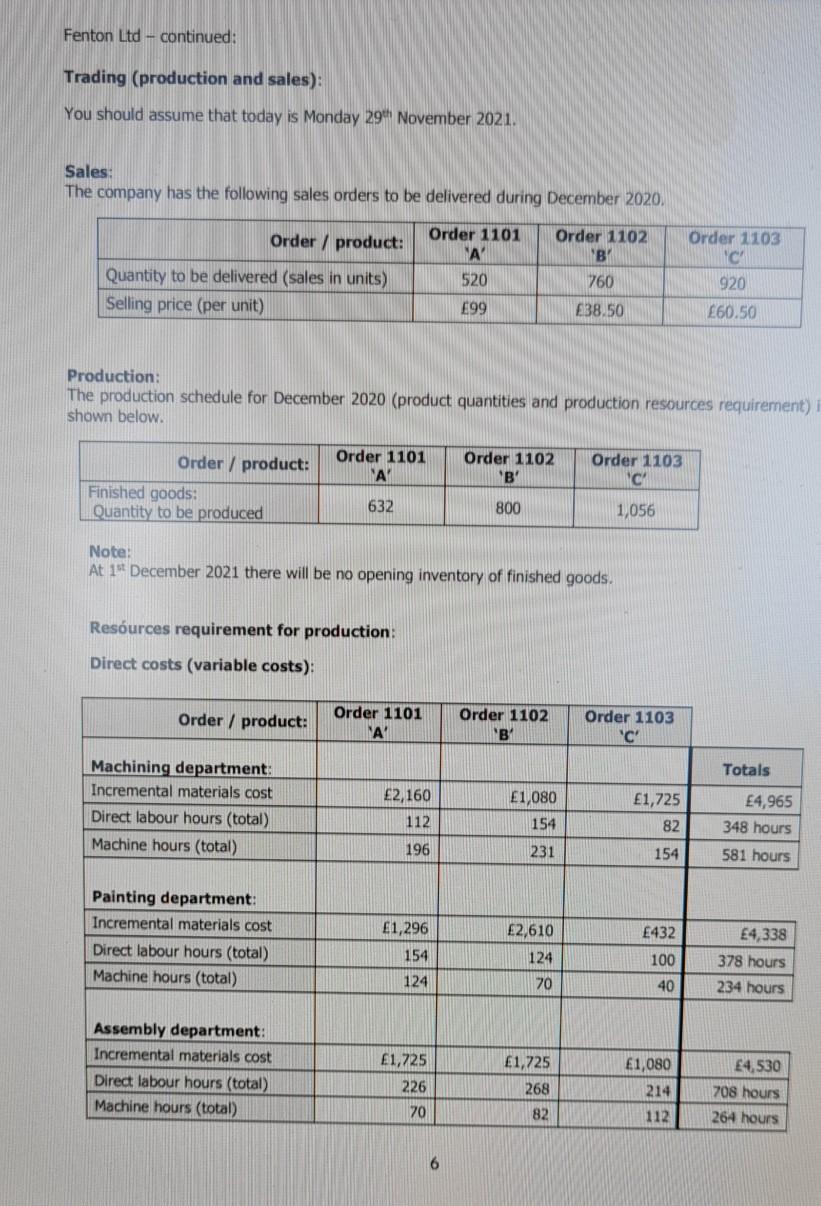

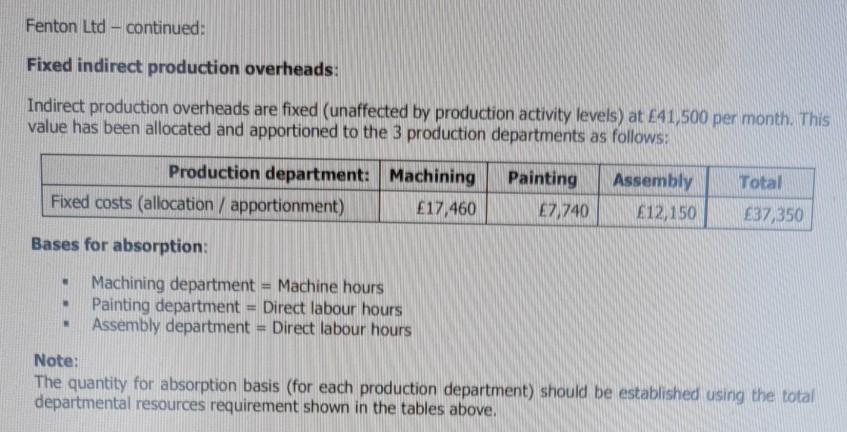

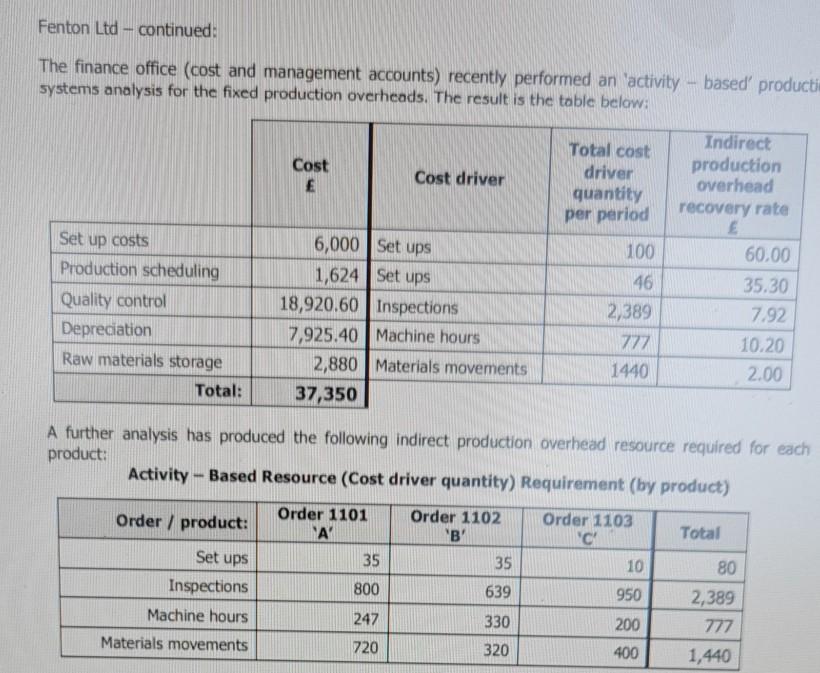

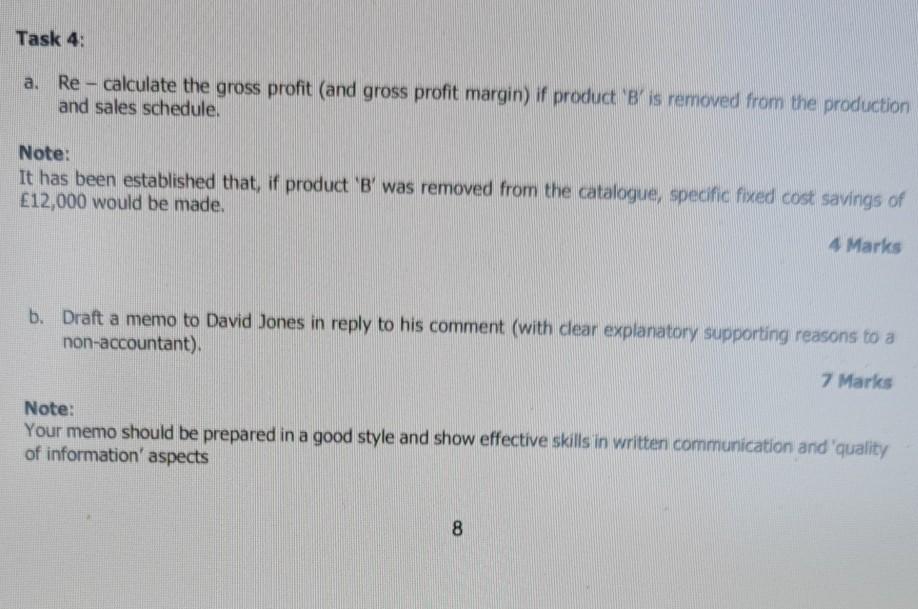

Fenton Ltd Fenton Ltd is a manufacturing organisation supplying specialised engineered products to a wide range o a public and private sector throughout the UK. You are a trainee in the finance office recently recruited by the company. Management planning meeting: On the 29th of every month (or nearest Monday) the business executive management team meets to plan trading and production for the following month. The meeting commences with a review of the sales order book and a determination of the following months product sales volumes. The expected sales volumes inform the production planning process and decisions are made with respect to production resources and closing inventory requirements. The agreed plan is the production schedule document. This is forwarded to the production departmental managers who will examine and compare their available resources against the requirement for production. Any problems (constraints) or other issues arising are reported back to the executive management team who will consider making adjustments to: The production requirements The available resources At the start of the following month, the production process will commence with a view to meeting the objectives of the agreed production (action) plan This process is described by the production planning flowchart (shown below): Production Planning Flowchart Start 29th of the Month (or nearest Monday); Executive management planning meeting for the next month's trading objectives: Expected sales determination Production output levels for the following month. . Management adjustments to original plan data Plan document passed to functional production managers Y N Problems / constraints V other issues arising? Agreed action plan document ready for the following month's production process End Fenton Ltd - continued: Fenton Ltd - Production Process Flowchart Start Materials movement process Machining department: Direct materials Add Direct labour (11.00 per hour) Add Direct expenses (E6.00 per machine hour) Add Fixed indirect production overhead costs absorbed = Total cost of machined goods (Transferred out to painting department) Materials movements and internal transfer inspection processes aterials movements nd internal transfer spection processes . Painting department: Direct materials Add machined goods transferred IN Add Direct labour (13.00 per hour) Add Direct expenses (4.00 per machine hour) Add Fixed indirect production overhead costs absorbed = Total cost of painted goods (Transferred out to assembly department) . Assembly department: Direct materials Add painted goods transferred IN Add Direct labour (9.00 per hour) Add Direct expenses (5.00 per machine hour) Add Fixed indirect production overhead costs absorbed = Total cost of saleable finished goods produced (Transferred out to finished goods warehouse) Materials movements and internal transfer inspection processes Finished goods warehouse Fnd Note: . The costs of materials movements between departments and internal inspection checks are included in indirect production overheads. The above flowchart is an outline process only and does not include control decision, documentation raising and filing requirements, . Fenton Ltd - continued: Goods receiving and locating / storage control process: When goods are received to the business raw materials stores, they are first checked by the store keeper for quantity against a copy of the original purchase order document (this is forwarded to the raw materials stores at the time that the order is placed - with all money values removed). If the quantity is incorrect (allowing for approved part-order deliveries) a 'Quantity rejection note' is prepared. Goods that are acceptable by quantity are quality inspected for size, weight, colour etc. Where goods are found to be unacceptable by quality, a 'Quality rejection note' is prepared. Goods rejected by quantity or quality are located at the 'Returns room' ready for return to the supplier. Acceptable goods are initially identified as either Alpha' or 'Beta'. Alpha: Alphas that are 'Square' are to be located at A01 If the Alphas are not Square' are 'Round'. "Round' Alphas are further sub-analysed as 'Clear' or Opaque'. Alphas that are "Clear' should be located at 'AO2', otherwise the "Opaque' Alphas should be located at 'A03. Beta: Betas that are 'Pentagon' should be located at 'B01 3 Betas that are not 'Pentagon' are 'Hexagon'. Hexagon' Betas are further sub-analysed as either "Large' or 'Small'. 'Large Betas' should be located at 'BO2'; otherwise the 'Small Betas' are to be located at 'B03. After goods received have carefully and accurately been located, the store keeper will prepare a 'goods received note' (GRN). This will be forwarded to the finance office. Fenton Ltd - continued: Trading (production and sales): You should assume that today is Monday 29th November 2021. Sales: The company has the following sales orders to be delivered during December 2020, Order product: Order 1101 NA 520 Order 1102 B 760 38.50 Order 1103 C 920 Quantity to be delivered (sales in units) Selling price (per unit) E99 60.50 Production: The production schedule for December 2020 (product quantities and production resources requirement) shown below. Order 1101 A Order 1102 'B' er / product: Finished goods: Quantity to be produced Order 1103 CA 632 800 1,056 Note: At 14 December 2021 there will be no opening inventory of finished goods. Resources requirement for production: Direct costs (variable costs) Order / product: Order 1101 A Order 1102 B Order 1103 'C' Totals Machining department: Incremental materials cost Direct labour hours (total) Machine hours (total) 2,160 112 1,080 154 1,725 4,965 348 hours 82 196 231 154 581 hours Painting department: Incremental materials cost Direct labour hours (total) Machine hours (total) E2,610 E432 1,296 154 124 100 40 4,338 378 hours 234 hours 124 70 Assembly department: Incremental materials cost Direct labour hours (total) Machine hours (total) 1,080 1,725 226 70 1,725 268 82 4,530 708 hours 214 112 264 hours 6 Fenton Ltd - continued: Fixed indirect production overheads: Indirect production overheads are fixed (unaffected by production activity levels) at 41,500 per month. This value has been allocated and apportioned to the 3 production departments as follows: Production department: Machining Fixed costs (allocation / apportionment) E17,460 Painting 7,740 Assembly 12,150 Total 37,350 Bases for absorption: Machining department = Machine hours Painting department = Direct labour hours Assembly department = Direct labour hours Note: The quantity for absorption basis (for each production department) should be established using the total departmental resources requirement shown in the tables above, Fenton Ltd - continued: The finance office (cost and management accounts) recently performed an 'activity based product systems analysis for the fixed production overheads. The result is the table below: Cost E Cost driver Total cost driver quantity per period Indirect production overhead recovery rate Set up costs Production scheduling Quality control Depreciation Raw materials storage Total: 6,000 Set ups 1,624 Set ups 18,920.60 Inspections 7,925.40 Machine hours 2,880 Materials movements 37,350 100 46 2,389 777 1440 60.00 35.30 7.92 10.20 2.00 A further analysis has produced the following indirect production overhead resource required for each product: Activity - Based Resource (Cost driver quantity) Requirement (by product) Order 1101 Order / product: Order 1102 Order 1103 AP Total 'B' CH 35 10 80 Inspections 800 639 950 2,389 Machine hours 247 330 200 777 Materials movements 720 320 400 1,440 Set ups 35 Task 4: a. Re - calculate the gross profit (and gross profit margin) if product 'B' is removed from the production and sales schedule. Note: It has been established that, if product 'B' was removed from the catalogue, specific fixed cost savings of 12,000 would be made. Marks b. Draft a memo to David Jones in reply to his comment (with clear explanatory supporting reasons to a non-accountant) 7 Marks Note: Your memo should be prepared in a good style and show effective skills in written communication and quality of information' aspects 8 Fenton Ltd Fenton Ltd is a manufacturing organisation supplying specialised engineered products to a wide range o a public and private sector throughout the UK. You are a trainee in the finance office recently recruited by the company. Management planning meeting: On the 29th of every month (or nearest Monday) the business executive management team meets to plan trading and production for the following month. The meeting commences with a review of the sales order book and a determination of the following months product sales volumes. The expected sales volumes inform the production planning process and decisions are made with respect to production resources and closing inventory requirements. The agreed plan is the production schedule document. This is forwarded to the production departmental managers who will examine and compare their available resources against the requirement for production. Any problems (constraints) or other issues arising are reported back to the executive management team who will consider making adjustments to: The production requirements The available resources At the start of the following month, the production process will commence with a view to meeting the objectives of the agreed production (action) plan This process is described by the production planning flowchart (shown below): Production Planning Flowchart Start 29th of the Month (or nearest Monday); Executive management planning meeting for the next month's trading objectives: Expected sales determination Production output levels for the following month. . Management adjustments to original plan data Plan document passed to functional production managers Y N Problems / constraints V other issues arising? Agreed action plan document ready for the following month's production process End Fenton Ltd - continued: Fenton Ltd - Production Process Flowchart Start Materials movement process Machining department: Direct materials Add Direct labour (11.00 per hour) Add Direct expenses (E6.00 per machine hour) Add Fixed indirect production overhead costs absorbed = Total cost of machined goods (Transferred out to painting department) Materials movements and internal transfer inspection processes aterials movements nd internal transfer spection processes . Painting department: Direct materials Add machined goods transferred IN Add Direct labour (13.00 per hour) Add Direct expenses (4.00 per machine hour) Add Fixed indirect production overhead costs absorbed = Total cost of painted goods (Transferred out to assembly department) . Assembly department: Direct materials Add painted goods transferred IN Add Direct labour (9.00 per hour) Add Direct expenses (5.00 per machine hour) Add Fixed indirect production overhead costs absorbed = Total cost of saleable finished goods produced (Transferred out to finished goods warehouse) Materials movements and internal transfer inspection processes Finished goods warehouse Fnd Note: . The costs of materials movements between departments and internal inspection checks are included in indirect production overheads. The above flowchart is an outline process only and does not include control decision, documentation raising and filing requirements, . Fenton Ltd - continued: Goods receiving and locating / storage control process: When goods are received to the business raw materials stores, they are first checked by the store keeper for quantity against a copy of the original purchase order document (this is forwarded to the raw materials stores at the time that the order is placed - with all money values removed). If the quantity is incorrect (allowing for approved part-order deliveries) a 'Quantity rejection note' is prepared. Goods that are acceptable by quantity are quality inspected for size, weight, colour etc. Where goods are found to be unacceptable by quality, a 'Quality rejection note' is prepared. Goods rejected by quantity or quality are located at the 'Returns room' ready for return to the supplier. Acceptable goods are initially identified as either Alpha' or 'Beta'. Alpha: Alphas that are 'Square' are to be located at A01 If the Alphas are not Square' are 'Round'. "Round' Alphas are further sub-analysed as 'Clear' or Opaque'. Alphas that are "Clear' should be located at 'AO2', otherwise the "Opaque' Alphas should be located at 'A03. Beta: Betas that are 'Pentagon' should be located at 'B01 3 Betas that are not 'Pentagon' are 'Hexagon'. Hexagon' Betas are further sub-analysed as either "Large' or 'Small'. 'Large Betas' should be located at 'BO2'; otherwise the 'Small Betas' are to be located at 'B03. After goods received have carefully and accurately been located, the store keeper will prepare a 'goods received note' (GRN). This will be forwarded to the finance office. Fenton Ltd - continued: Trading (production and sales): You should assume that today is Monday 29th November 2021. Sales: The company has the following sales orders to be delivered during December 2020, Order product: Order 1101 NA 520 Order 1102 B 760 38.50 Order 1103 C 920 Quantity to be delivered (sales in units) Selling price (per unit) E99 60.50 Production: The production schedule for December 2020 (product quantities and production resources requirement) shown below. Order 1101 A Order 1102 'B' er / product: Finished goods: Quantity to be produced Order 1103 CA 632 800 1,056 Note: At 14 December 2021 there will be no opening inventory of finished goods. Resources requirement for production: Direct costs (variable costs) Order / product: Order 1101 A Order 1102 B Order 1103 'C' Totals Machining department: Incremental materials cost Direct labour hours (total) Machine hours (total) 2,160 112 1,080 154 1,725 4,965 348 hours 82 196 231 154 581 hours Painting department: Incremental materials cost Direct labour hours (total) Machine hours (total) E2,610 E432 1,296 154 124 100 40 4,338 378 hours 234 hours 124 70 Assembly department: Incremental materials cost Direct labour hours (total) Machine hours (total) 1,080 1,725 226 70 1,725 268 82 4,530 708 hours 214 112 264 hours 6 Fenton Ltd - continued: Fixed indirect production overheads: Indirect production overheads are fixed (unaffected by production activity levels) at 41,500 per month. This value has been allocated and apportioned to the 3 production departments as follows: Production department: Machining Fixed costs (allocation / apportionment) E17,460 Painting 7,740 Assembly 12,150 Total 37,350 Bases for absorption: Machining department = Machine hours Painting department = Direct labour hours Assembly department = Direct labour hours Note: The quantity for absorption basis (for each production department) should be established using the total departmental resources requirement shown in the tables above, Fenton Ltd - continued: The finance office (cost and management accounts) recently performed an 'activity based product systems analysis for the fixed production overheads. The result is the table below: Cost E Cost driver Total cost driver quantity per period Indirect production overhead recovery rate Set up costs Production scheduling Quality control Depreciation Raw materials storage Total: 6,000 Set ups 1,624 Set ups 18,920.60 Inspections 7,925.40 Machine hours 2,880 Materials movements 37,350 100 46 2,389 777 1440 60.00 35.30 7.92 10.20 2.00 A further analysis has produced the following indirect production overhead resource required for each product: Activity - Based Resource (Cost driver quantity) Requirement (by product) Order 1101 Order / product: Order 1102 Order 1103 AP Total 'B' CH 35 10 80 Inspections 800 639 950 2,389 Machine hours 247 330 200 777 Materials movements 720 320 400 1,440 Set ups 35 Task 4: a. Re - calculate the gross profit (and gross profit margin) if product 'B' is removed from the production and sales schedule. Note: It has been established that, if product 'B' was removed from the catalogue, specific fixed cost savings of 12,000 would be made. Marks b. Draft a memo to David Jones in reply to his comment (with clear explanatory supporting reasons to a non-accountant) 7 Marks Note: Your memo should be prepared in a good style and show effective skills in written communication and quality of information' aspects 8

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts