Question: Please work problem 2. Problem 1. Your job is to design a sieve tray column to distill a mixture of dichloromethane, chloroform, and carbon tetrachlonide.

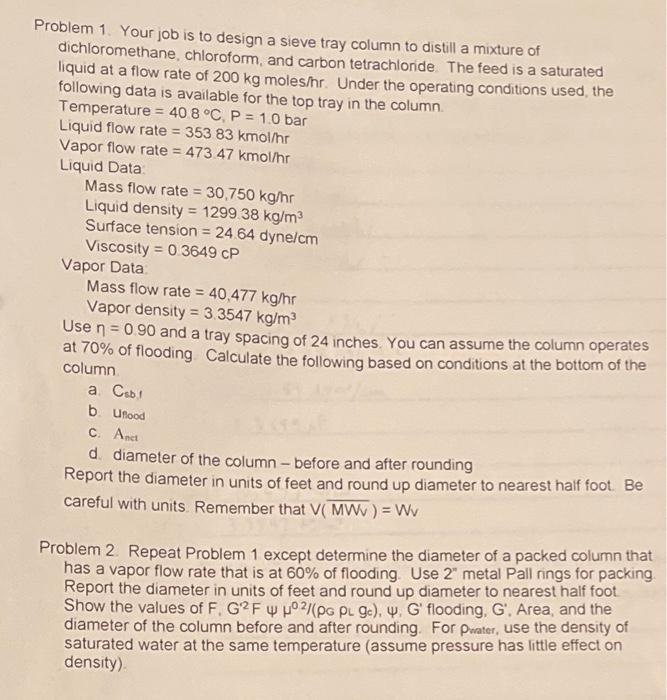

Problem 1. Your job is to design a sieve tray column to distill a mixture of dichloromethane, chloroform, and carbon tetrachlonide. The feed is a saturated liquid at a flow rate of 200kg moles /hr. Under the operating conditions used, the following data is available for the top tray in the column. Temperature =40.8C,P=1.0 bar Liquid flow rate =35383kmol/hr Vapor flow rate =473.47kmol/hr Liquid Data: Mass flow rate =30,750kg/hr Liquid density =1299.38kg/m3 Surface tension =24.64dyne/cm Viscosity =03649cP Vapor Data: Mass flow rate =40,477kg/hr Vapor density =3.3547kg/m3 Use =0.90 and a tray spacing of 24 inches. You can assume the column operates at 70% of flooding Calculate the following based on conditions at the bottom of the column. a. Cibl1 b. Usood c. Anat d. diameter of the column - before and after rounding Report the diameter in units of feet and round up diameter to nearest half foot. Be careful with units. Remember that V(MWV)=Wv Problem 2. Repeat Problem 1 except determine the diameter of a packed column that has a vapor flow rate that is at 60% of flooding. Use 2n metal Pall rings for packing. Report the diameter in units of feet and round up diameter to nearest half foot. Show the values of F,G2F02/(oLgc),,G flooding, G'. Area, and the diameter of the column before and after rounding. For prater, use the density of saturated water at the same temperature (assume pressure has little effect on density)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts