Question: Please write the code for Access to solve this questions no need to write how to create the tables they are created with the data

Please write the code for Access to solve this questions

no need to write how to create the tables they are created with the data with the same names mentioned above each table.

(MACHINE , PART , PROCESS_PLAN , SCHEDULE )

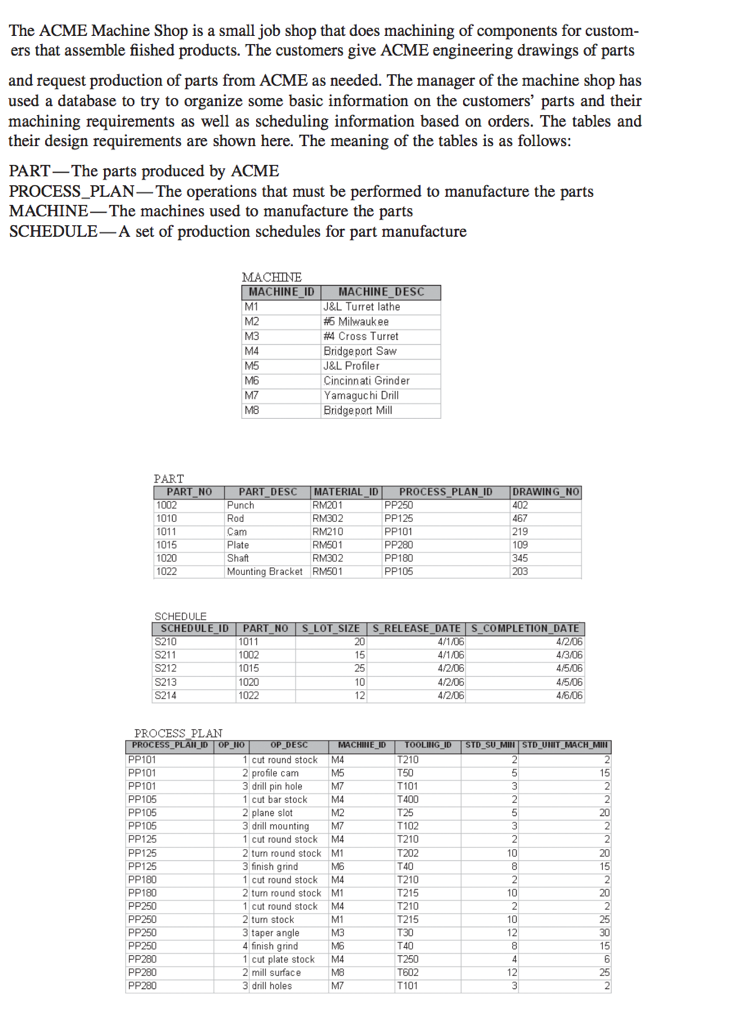

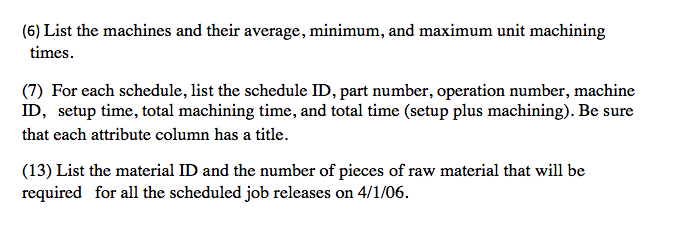

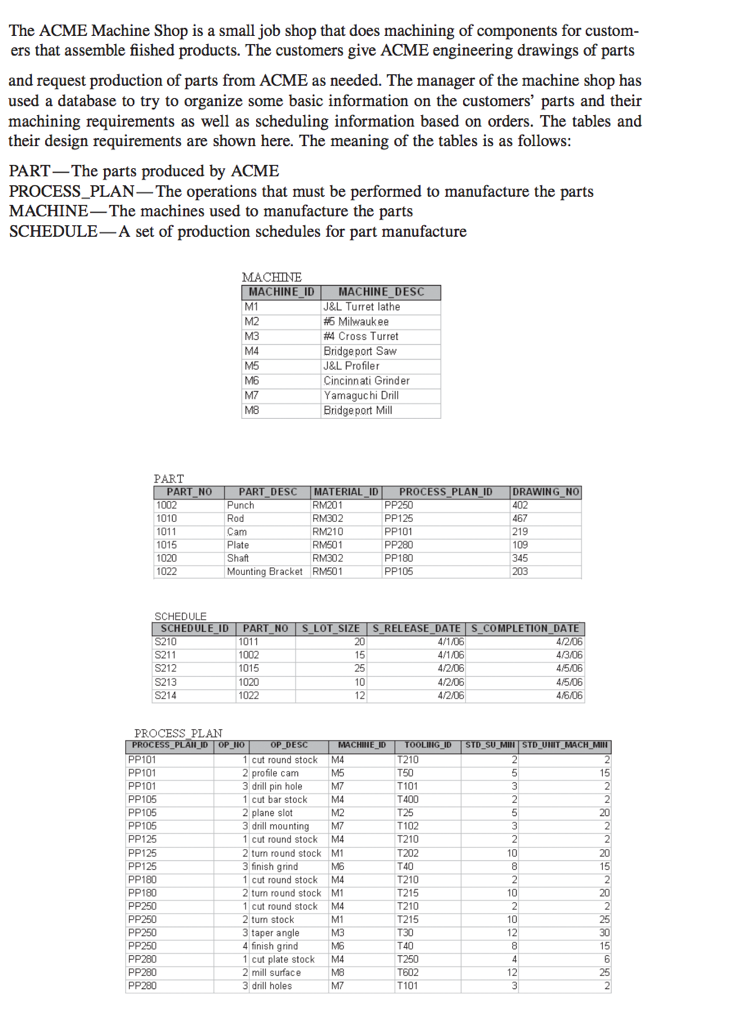

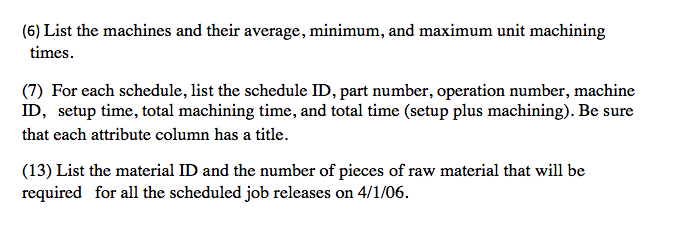

The ACME Machine Shop is a small job shop that does machining of components for custom- ers that assemble fiished products. The customers give ACME engineering drawings of parts and request production of parts from ACME as needed. The manager of the machine shop has used a database to try to organize some basic information on the customers' parts and their machining requirements as well as scheduling information based on orders. The tables and their design requirements are shown here. The meaning of the tables is as follows: PART The parts produced by ACME PROCESS_PLAN The operations that must be performed to manufacture the parts MACHINE- The machines used to manufacture the parts SCHEDULEA set of production schedules for part manufacture MACHINE MACHINE_ID MACHINE_DESC M1 J&L Turret lathe M2 #6 Milwaukee M3 #4 Cross Turret M4 Bridgeport Saw M5 J&L Profiler M6 Cincinnati Grinder M7 Yamaguchi Drill M8 Bridgeport Mill PART PART_NO PART DESC MATERIAL_ID PROCESS PLAN ID 1002 Punch RM201 PP250 1010 Rod RM302 PP125 1011 Cam RM210 PP101 1015 Plate RM501 PP280 1020 Shaft RM302 PP180 1022 Mounting Bracket RM501 PP105 DRAWING NO 402 467 219 109 345 203 SCHEDULE SCHEDULE_ID PART_NO S_LOT_SIZE S_RELEASE_DATE S_COMPLETION_DATE S210 1011 20 4/1/06 4/2/06 S211 1002 15 4/1/06 4/3/06 S212 1015 25 4/2/06 4/5/06 S213 1020 10 4/2/06 45/06 S214 1022 12 4/2/06 4/6/06 PROCESS PLAN PROCESS_PLANI_ID OP_110 OP_DESC MACHITE_ID PP101 1 cut round stock M4 PP101 2 profile cam M5 PP101 3 drill pin hole MY PP105 1 cut bar stock M4 PP105 2 plane slot M2 PP105 3 drill mounting M7 PP125 1 cut round stock M4 PP125 2 tum round stock M1 PP125 3 finish grind M6 PP180 1 cut round stock M4 PP180 2 tum round stock M1 PP250 1 cut round stock M4 PP250 2 turn stock M1 PP250 3 taper angle M3 PP250 4 finish grind PP280 1 cut plate stock M4 PP280 2 mill surface MB PP280 3 drill holes M7 TOOLILIG_ID T210 T50 T101 T400 T25 T102 T210 T202 T40 T210 T215 T210 T215 T30 T40 T250 T602 T101 STD_SU_MUSTD_UNIT_MACH_MIN 2 2 5 15 3 3 2 2 2 5 20 3 2 2 2 10 20 8 15 2 2 10 20 2 2 10 25 12 30 8 15 4 6 12 25 3 2 (6) List the machines and their average, minimum, and maximum unit machining times. (7) For each schedule, list the schedule ID, part number, operation number, machine ID, setup time, total machining time, and total time (setup plus machining). Be sure that each attribute column has a title. (13) List the material ID and the number of pieces of raw material that will be required for all the scheduled job releases on 4/1/06