Question: ** Plese show all work, formulas, and calculations. Please setup the table and provide as text based or work/excel file with table setup (the table

** Plese show all work, formulas, and calculations. Please setup the table and provide as text based or work/excel file with table setup (the table below may be copied as a template for answer). This is a multiple step/answer question so all answers are needed.

Material handling truck routing:

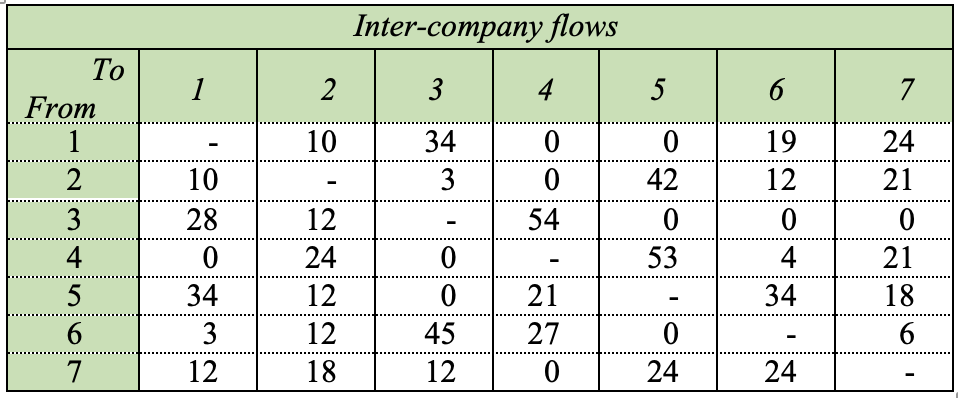

An 18-wheeler is used to move work-in-process (WIP) among the pickup and delivery depot locations. The following table contains inter-location moves per 8-hour shift. The inter-location flow rates are assumed constant through the 8-hour shift.

(Text version below)

| To From | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 1 | - | 10 | 0 | 0 | 0 | 19 | 24 |

| 2 | 10 | - | 3 | 0 | 42 | 12 | 21 |

| 3 | 28 | 12 | - | 20 | 0 | 0 | 0 |

| 4 | 0 | 24 | 0 | - | 19 | 4 | 21 |

| 5 | 0 | 12 | 0 | 21 | - | 34 | 18 |

| 6 | 3 | 12 | 45 | 27 | 0 | - | 6 |

| 7 | 12 | 18 | 12 | 0 | 24 | 24 | - |

A) Determine the most frequent cyclic route (with the number of cyclic moves) for the 18-wheeler to minimize empty travel. Choose the first available destination if there is a tie.

B) What is the resulting move-matrix?

C) What percent of the total moves is completed by each route?

Inter-company flows 1 2 3 4 5 6 7 10 34 3 - To From 1 2 3 4 5 6 7 0 0 54 0 42 0 53 - 10 28 0 34 3 12 19 12 0 4 34 12 24 12 12 18 1 24 21 0 21 18 6 0 0 45 12 21 27 0 0 24 24Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts