Question: pls help me answer a and b asap. Question 3 (a) Figure Q3.1 shows a spray drying system used to produce instant milk powders. Feed

pls help me answer a and b asap.

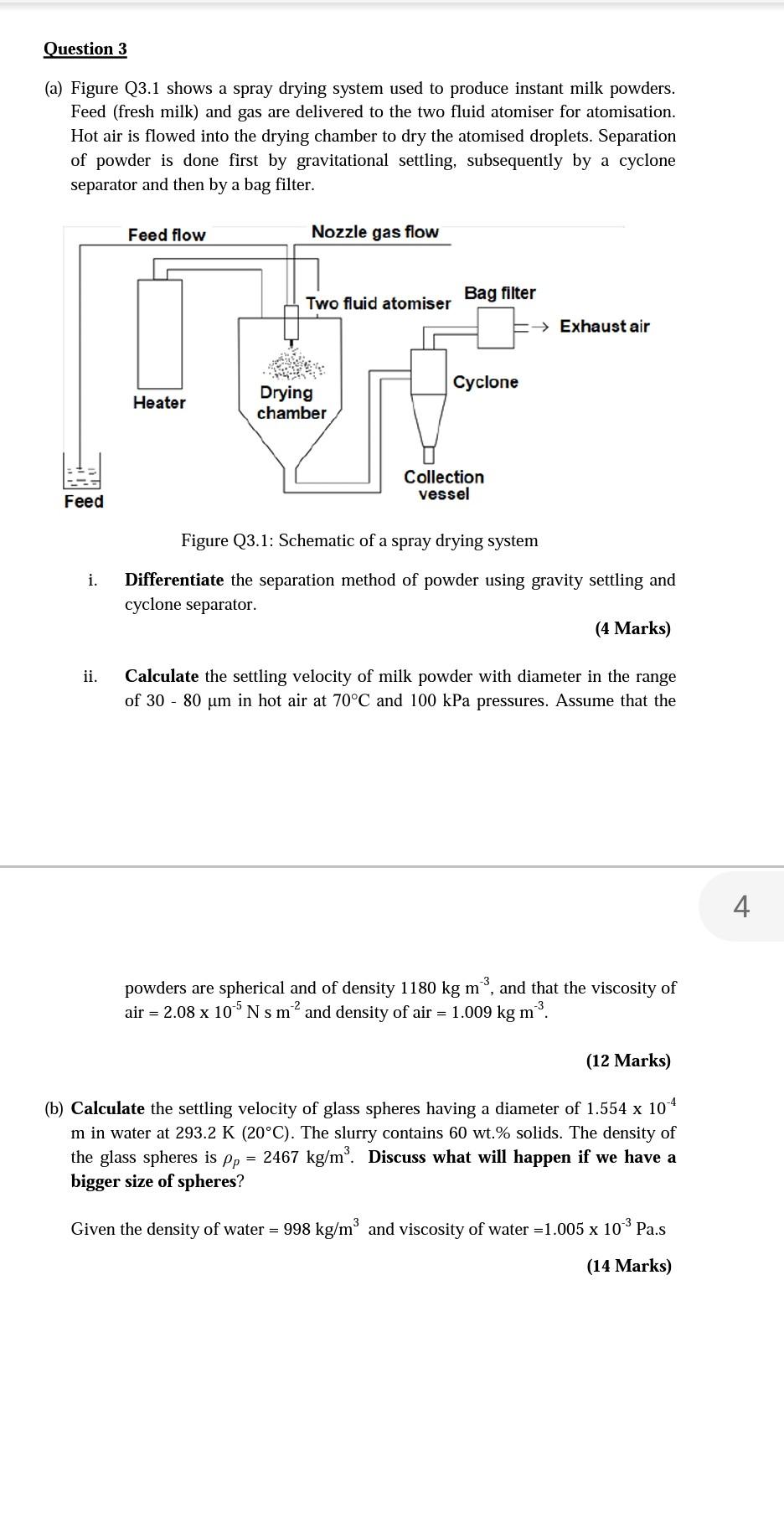

Question 3 (a) Figure Q3.1 shows a spray drying system used to produce instant milk powders. Feed (fresh milk) and gas are delivered to the two fluid atomiser for atomisation. Hot air is flowed into the drying chamber to dry the atomised droplets. Separation of powder is done first by gravitational settling, subsequently by a cyclone separator and then by a bag filter. Feed flow Nozzle gas flow Two fluid atomiser Bag filter > Exhaust air Cyclone Heater Drying chamber Collection vessel Feed Figure Q3.1: Schematic of a spray drying system i. Differentiate the separation method of powder using gravity settling and cyclone separator. (4 Marks) ii. Calculate the settling velocity of milk powder with diameter in the range of 30 - 80 um in hot air at 70C and 100 kPa pressures. Assume that the 4 powders are spherical and of density 1180 kg m and that the viscosity of air = 2.08 x 10"Nsm and density of air = 1.009 kg m?. (12 Marks) (b) Calculate the settling velocity of glass spheres having a diameter of 1.554 x 104 m in water at 293.2 K (20C). The slurry contains 60 wt.% solids. The density of the glass spheres is pp = 2467 kg/m Discuss what will happen if we have a bigger size of spheres? Given the density of water = 998 kg/m and viscosity of water =1.005 x 10-3 Pa.s (14 Marks)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts