Question: Plz answer Q 24 and 25 Question 24 Not yet answered Marked out of 1.50 Flag question A manufacturer is designing a product layout for

Plz answer Q 24 and 25

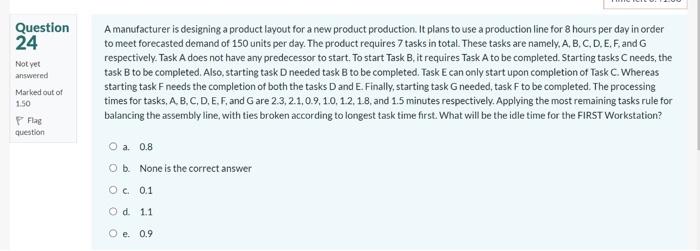

Question 24 Not yet answered Marked out of 1.50 Flag question A manufacturer is designing a product layout for a new product production. It plans to use a production line for 8 hours per day in order to meet forecasted demand of 150 units per day. The product requires 7 tasks in total. These tasks are namely, A, B, C, D, E, F, and G respectively. Task A does not have any predecessor to start. To start Task B, it requires Task A to be completed. Starting tasks C needs, the task B to be completed. Also, starting task Dneeded task B to be completed. Task E can only start upon completion of Task C. Whereas starting task F needs the completion of both the tasks D and E. Finally, starting task G needed task F to be completed. The processing times for tasks, A, B, C, D, E, F, and Gare 2.3, 2.1,0.9, 1.0, 1.2, 1.8, and 1.5 minutes respectively. Applying the most remaining tasks rule for balancing the assembly line, with ties broken according to longest task time first. What will be the idle time for the FIRST Workstation? O a 0.8 Ob None is the correct answer OC 0.1 Od 1.1 Oe. 0.9 Time left Question 25 Maximum cycle time is the sum of all task times when the tasks are running in parallel (all at the same time). O a FALSE O b. TRUE Not yet answered Marked out of 0.25 P Flag

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock