Question: PMT 3306: Quality anagement Systems CASE PROBLEM 3.1 Quality Control at Rainwater Brewery carbonated and the beer ages for about a week with the Bob

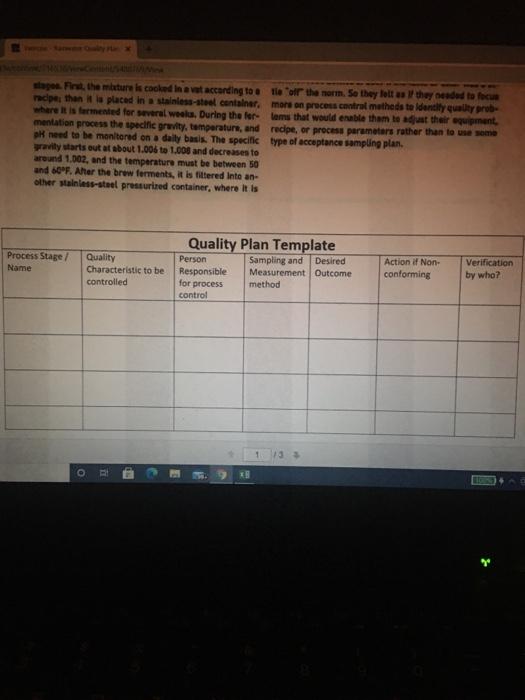

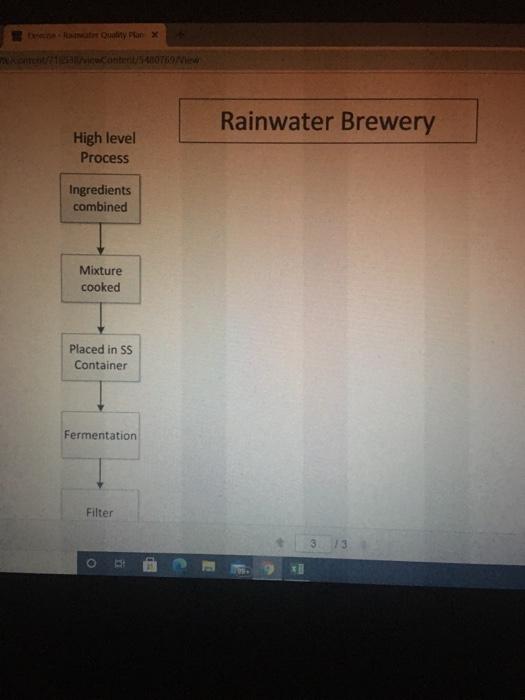

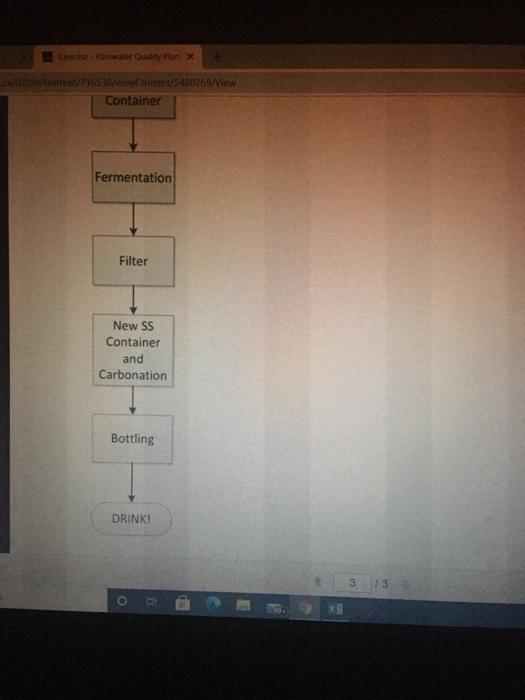

PMT 3306: Quality anagement Systems CASE PROBLEM 3.1 Quality Control at Rainwater Brewery carbonated and the beer ages for about a week with the Bob Raines and Megan Waters own and operate the Rain temperature monitored, after which it is bottled and is water Brewery, a micro-brewery that grew out of their ready for distribution. Megan and Bob brow a batch of shared hobby of making home-brew. The brewery is lo- beer each day, which will result in about 1000 bottles for cated in Whitesville, the home of State University where distribution after the approximately three-week termen- Bob and Megan went to college. tation and aging process. Whitesville has a number of bars and restaurants that In the process of setting up their brewery, Megan and are patronized by students at State and the local resident Bob agreed they had already developed a proven product population. In fact, Whitesville has the highest per capita with a taste that was appealing, so the most important beer consumption in the state. In setting up their small factor in the success of their new venture would be main- brewery, Bob and Megan decided that they would target taining high quality. Thus, they spent a lot of time dis- their sales toward individuals who would pick up their or- cussing what kind of quality control techniques they ders directly from the brewery and toward restaurants should employ. They agreed that the chance of brewing a and bars, where they would deliver orders on a daily or "bad" er "spoiled."batch of beer was extremely remote weekly basis. plus they could not financially afford to reject a whole The brewery process essentially occurs in three batch of 1000 bottles of beer if the taste or coler was a lit- stages. First, the mixture is cooked in a vat according to a tle of the norm. So they felt as if they needed to focus recipe then it is placed in a stainless steel container, more on process control methods to identity quality prob 1 133 O G E M po First, the mature is cooked in a vt according to the for the norm. Se they felt as they needed to focus nape, then les placed in a stainless steel container, more on process control methods te Identity quality prob where it is fermented for several weelu. During the fer lams that would enable them te adjust their equipment mentation process the specific gravity, temperature, and recipe, or process parameters rather than to use some pH need to be monitored on a daily basis. The specific type of acceptance sampling plan. ravily starts out at about 1.006 to 1.000 and decreases to around 1.002, and the temperature must be between 50 and 66F. Aher the brow ferments, it is fittered into an- other stainless steel pressurized container, where it is Process Stage / Name Quality Characteristic to be controlled Quality Plan Template Person Sampling and Desired Responsible Measurement Outcome for process method control Action if Non- conforming Verification by who? 133 21 ContentTRON Rainwater Brewery High level Process Ingredients combined Mixture cooked Placed in SS Container Fermentation Filter o more-Rainwater Qualy Planx wetent/71653B/ViewCont/5480761/View Container Fermentation Filter New SS Container and Carbonation Bottling DRINK! 3 PMT 3306: Quality anagement Systems CASE PROBLEM 3.1 Quality Control at Rainwater Brewery carbonated and the beer ages for about a week with the Bob Raines and Megan Waters own and operate the Rain temperature monitored, after which it is bottled and is water Brewery, a micro-brewery that grew out of their ready for distribution. Megan and Bob brow a batch of shared hobby of making home-brew. The brewery is lo- beer each day, which will result in about 1000 bottles for cated in Whitesville, the home of State University where distribution after the approximately three-week termen- Bob and Megan went to college. tation and aging process. Whitesville has a number of bars and restaurants that In the process of setting up their brewery, Megan and are patronized by students at State and the local resident Bob agreed they had already developed a proven product population. In fact, Whitesville has the highest per capita with a taste that was appealing, so the most important beer consumption in the state. In setting up their small factor in the success of their new venture would be main- brewery, Bob and Megan decided that they would target taining high quality. Thus, they spent a lot of time dis- their sales toward individuals who would pick up their or- cussing what kind of quality control techniques they ders directly from the brewery and toward restaurants should employ. They agreed that the chance of brewing a and bars, where they would deliver orders on a daily or "bad" er "spoiled."batch of beer was extremely remote weekly basis. plus they could not financially afford to reject a whole The brewery process essentially occurs in three batch of 1000 bottles of beer if the taste or coler was a lit- stages. First, the mixture is cooked in a vat according to a tle of the norm. So they felt as if they needed to focus recipe then it is placed in a stainless steel container, more on process control methods to identity quality prob 1 133 O G E M po First, the mature is cooked in a vt according to the for the norm. Se they felt as they needed to focus nape, then les placed in a stainless steel container, more on process control methods te Identity quality prob where it is fermented for several weelu. During the fer lams that would enable them te adjust their equipment mentation process the specific gravity, temperature, and recipe, or process parameters rather than to use some pH need to be monitored on a daily basis. The specific type of acceptance sampling plan. ravily starts out at about 1.006 to 1.000 and decreases to around 1.002, and the temperature must be between 50 and 66F. Aher the brow ferments, it is fittered into an- other stainless steel pressurized container, where it is Process Stage / Name Quality Characteristic to be controlled Quality Plan Template Person Sampling and Desired Responsible Measurement Outcome for process method control Action if Non- conforming Verification by who? 133 21 ContentTRON Rainwater Brewery High level Process Ingredients combined Mixture cooked Placed in SS Container Fermentation Filter o more-Rainwater Qualy Planx wetent/71653B/ViewCont/5480761/View Container Fermentation Filter New SS Container and Carbonation Bottling DRINK! 3