Question: Post by January 2 5 Comment by January 2 8 . Help each other out on the Q&A board. This company YPSI trailer is planning

Post by January Comment by January Help each other out on the Q&A board.

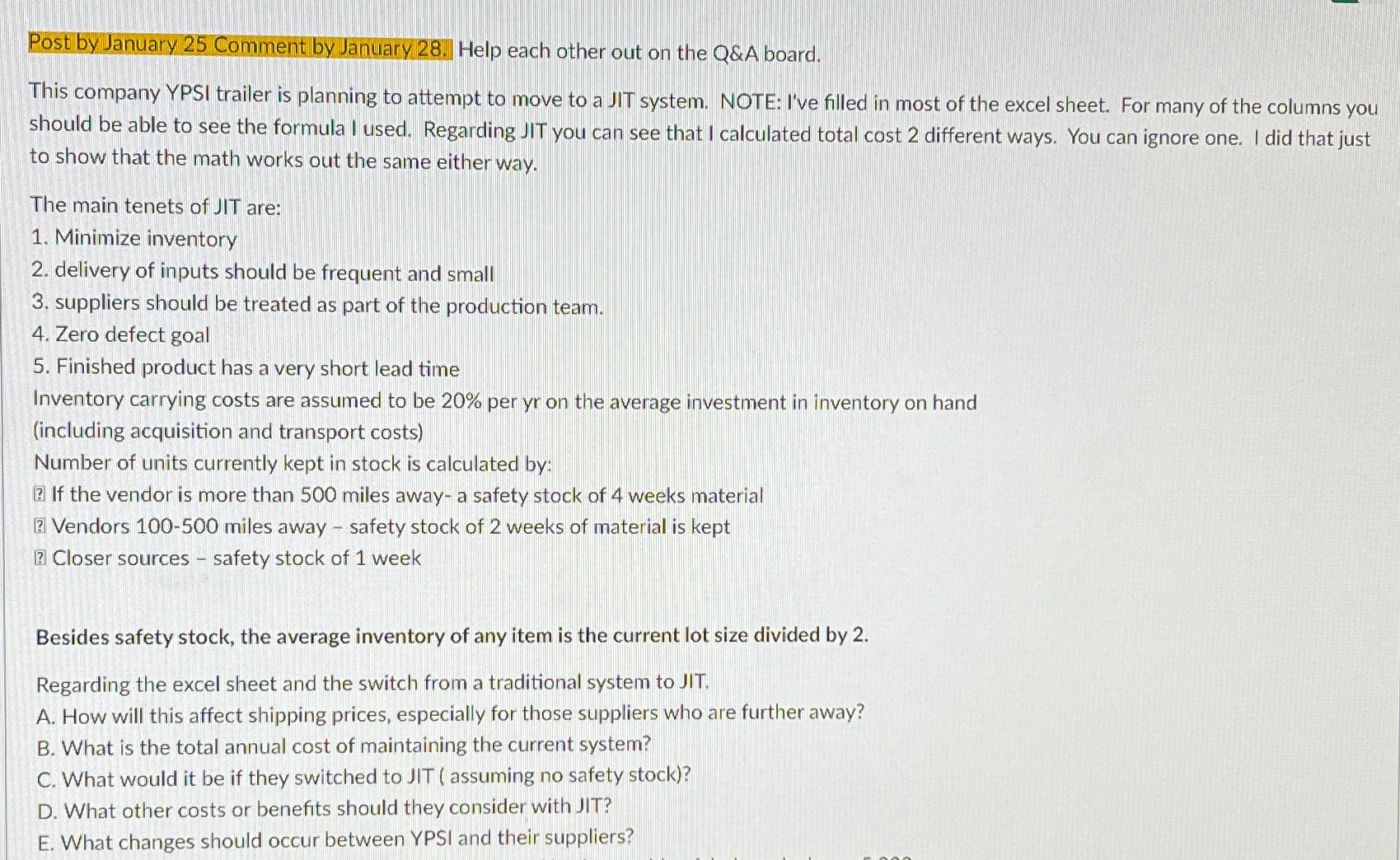

This company YPSI trailer is planning to attempt to move to a JIT system. NOTE: I've filled in most of the excel sheet. For many of the columns you should be able to see the formula I used. Regarding JIT you can see that I calculated total cost different ways. You can ignore one. I did that just to show that the math works out the same either way.

The main tenets of JIT are:

Minimize inventory

delivery of inputs should be frequent and small

suppliers should be treated as part of the production team.

Zero defect goal

Finished product has a very short lead time

Inventory carrying costs are assumed to be per yr on the average investment in inventory on hand including acquisition and transport costs

Number of units currently kept in stock is calculated by:

If the vendor is more than miles away a safety stock of weeks material

Vendors miles away safety stock of weeks of material is kept

Closer sources safety stock of week

Besides safety stock, the average inventory of any item is the current lot size divided by

Regarding the excel sheet and the switch from a traditional system to JIT.

A How will this affect shipping prices, especially for those suppliers who are further away?

B What is the total annual cost of maintaining the current system?

C What would it be if they switched to JIT assuming no safety stock

D What other costs or benefits should they consider with JIT?

E What changes should occur between YPSI and their suppliers?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock