Question: Prepare a BOM , also a Master production. the third pic has the question, rest have the needed information for reference Company Background Jane and

Prepare a BOM , also a Master production. the third pic has the question, rest have the needed information for reference

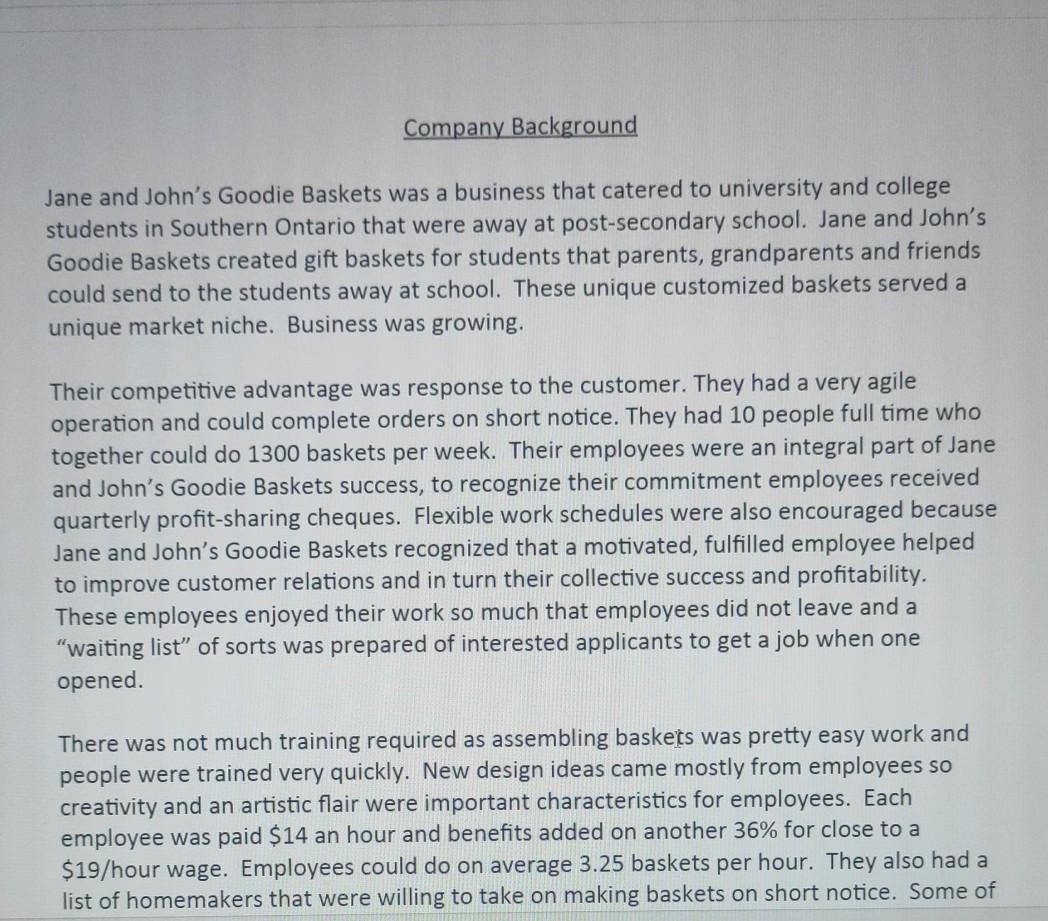

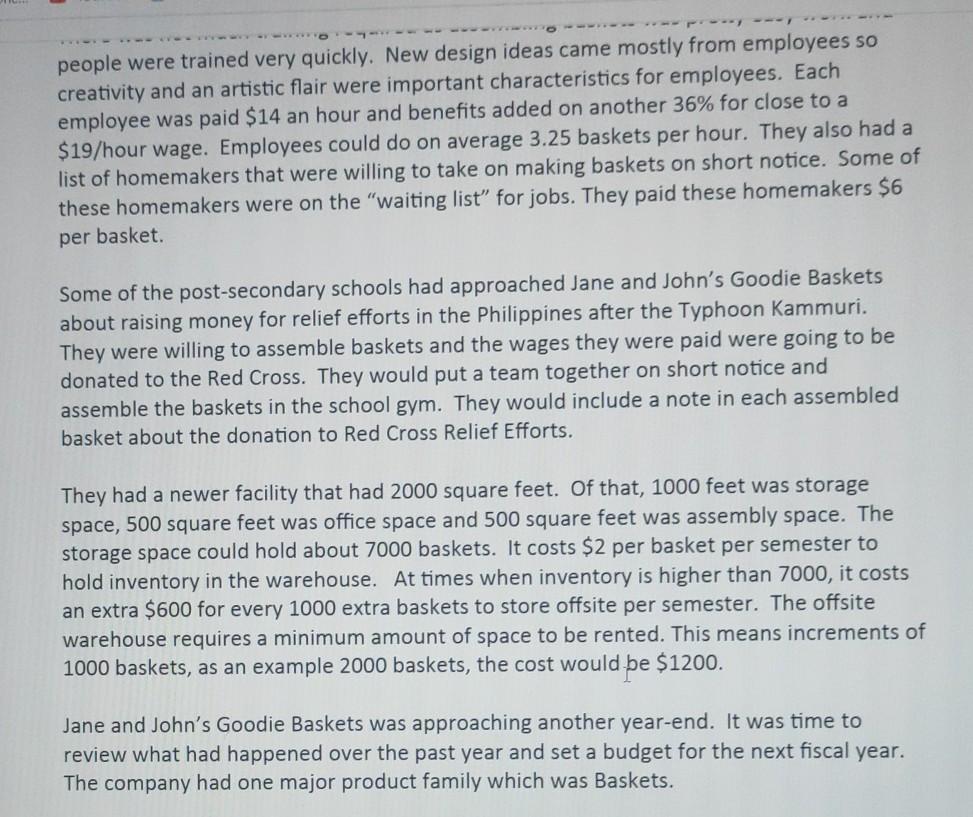

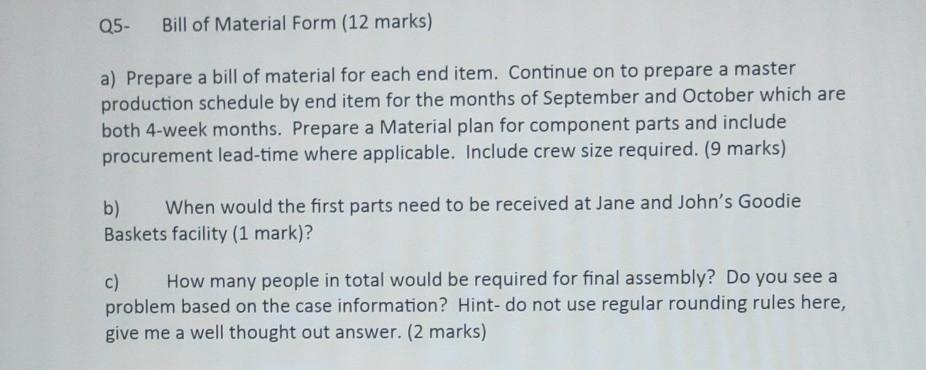

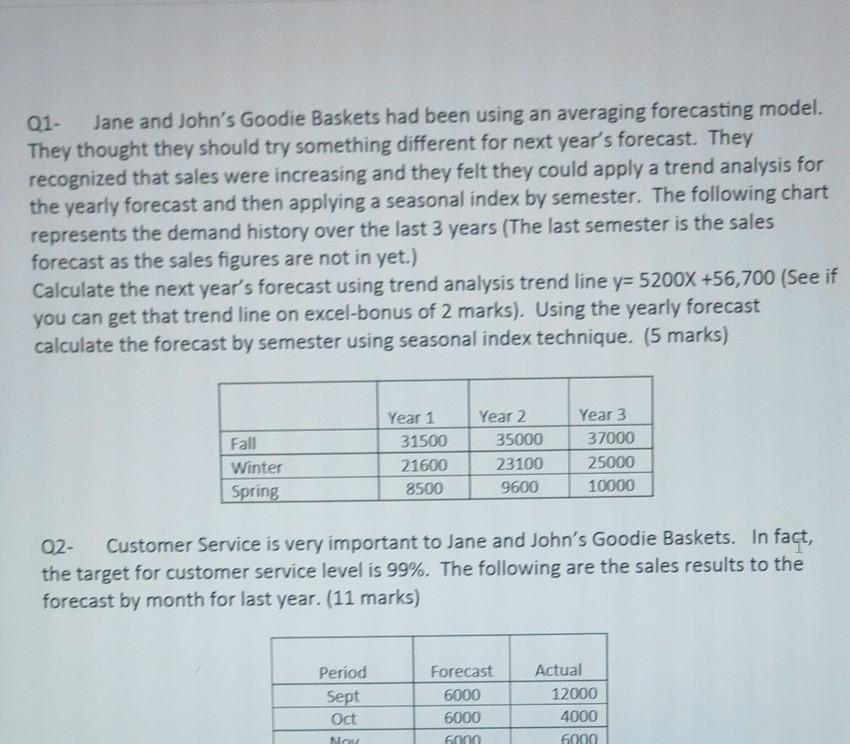

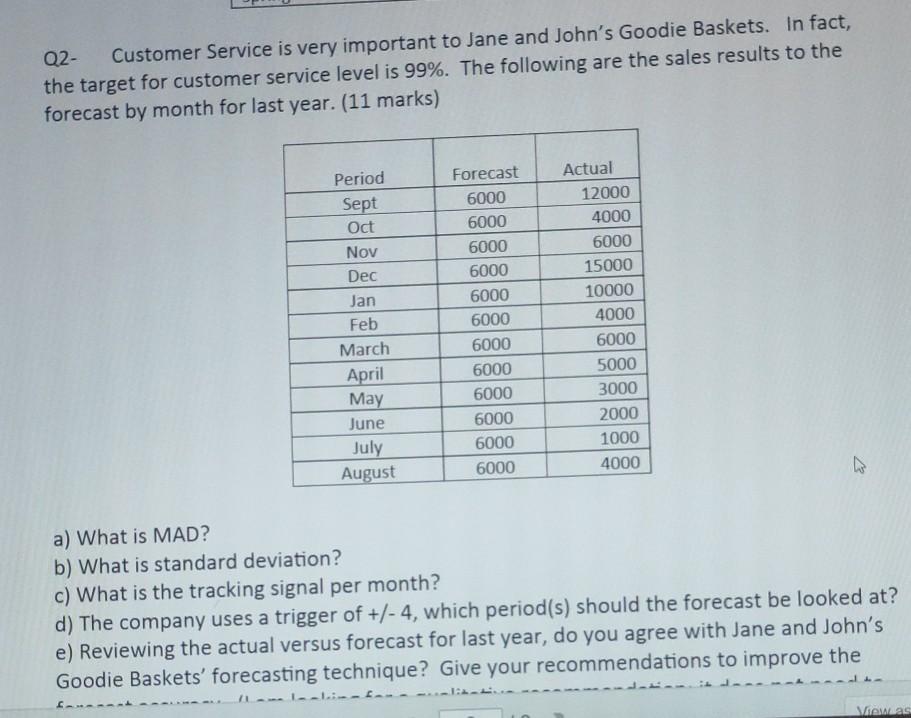

Company Background Jane and John's Goodie Baskets was a business that catered to university and college students in Southern Ontario that were away at post-secondary school. Jane and John's Goodie Baskets created gift baskets for students that parents, grandparents and friends could send to the students away at school. These unique customized baskets served a unique market niche. Business was growing. Their competitive advantage was response to the customer. They had a very agile operation and could complete orders on short notice. They had 10 people full time who together could do 1300 baskets per week. Their employees were an integral part of Jane and John's Goodie Baskets success, to recognize their commitment employees received quarterly profit-sharing cheques. Flexible work schedules were also encouraged because Jane and John's Goodie Baskets recognized that a motivated, fulfilled employee helped to improve customer relations and in turn their collective success and profitability. These employees enjoyed their work so much that employees did not leave and a "waiting list of sorts was prepared of interested applicants to get a job when one opened. There was not much training required as assembling baskets was pretty easy work and people were trained very quickly. New design ideas came mostly from employees so creativity and an artistic flair were important characteristics for employees. Each employee was paid $14 an hour and benefits added on another 36% for close to a $19/hour wage. Employees could do on average 3.25 baskets per hour. They also had a list of homemakers that were willing to take on making baskets on short notice. Some of ---- people were trained very quickly. New design ideas came mostly from employees so creativity and an artistic flair were important characteristics for employees. Each employee was paid $14 an hour and benefits added on another 36% for close to a $19/hour wage. Employees could do on average 3.25 baskets per hour. They also had a list of homemakers that were willing to take on making baskets on short notice. Some of these homemakers were on the "waiting list" for jobs. They paid these homemakers $6 per basket. Some of the post-secondary schools had approached Jane and John's Goodie Baskets about raising money for relief efforts in the Philippines after the Typhoon Kammuri. They were willing to assemble baskets and the wages they were paid were going to be donated to the Red Cross. They would put a team together on short notice and assemble the baskets in the school gym. They would include a note in each assembled basket about the donation to Red Cross Relief Efforts. They had a newer facility that had 2000 square feet. Of that, 1000 feet was storage space, 500 square feet was office space and 500 square feet was assembly space. The storage space could hold about 7000 baskets. It costs $2 per basket per semester to hold inventory in the warehouse. At times when inventory is higher than 7000, it costs an extra $600 for every 1000 extra baskets to store offsite per semester. The offsite warehouse requires a minimum amount of space to be rented. This means increments of 1000 baskets, as an example 2000 baskets, the cost would be $1200. Jane and John's Goodie Baskets was approaching another year-end. It was time to review what had happened over the past year and set a budget for the next fiscal year. The company had one major product family which was Baskets. Q5- Bill of Material Form (12 marks) a) Prepare a bill of material for each end item. Continue on to prepare a master production schedule by end item for the months of September and October which are both 4-week months. Prepare a Material plan for component parts and include procurement lead-time where applicable. Include crew size required. (9 marks) b) When would the first parts need to be received at Jane and John's Goodie Baskets facility (1 mark)? c) How many people in total would be required for final assembly? Do you see a problem based on the case information? Hint- do not use regular rounding rules here, give me a well thought out answer. (2 marks) 01- Jane and John's Goodie Baskets had been using an averaging forecasting model. They thought they should try something different for next year's forecast. They recognized that sales were increasing and they felt they could apply a trend analysis for the yearly forecast and then applying a seasonal index by semester. The following chart represents the demand history over the last 3 years (The last semester is the sales forecast as the sales figures are not in yet.) Calculate the next year's forecast using trend analysis trend line y= 5200X +56,700 (See if you can get that trend line on excel-bonus of 2 marks). Using the yearly forecast calculate the forecast by semester using seasonal index technique. (5 marks) Fall Winter Spring Year 1 31500 21600 8500 Year 2 35000 23100 9600 Year 3 37000 25000 10000 02- Customer Service is very important to Jane and John's Goodie Baskets. In fact, the target for customer service level is 99%. The following are the sales results to the forecast by month for last year. (11 marks) Period Sept Oct Forecast 6000 6000 Actual 12000 4000 6000 ann Q2- Customer Service is very important to Jane and John's Goodie Baskets. In fact, the target for customer service level is 99%. The following are the sales results to the forecast by month for last year. (11 marks) Period Sept Oct Nov Dec Jan Feb March April May June July August Forecast 6000 6000 6000 6000 6000 6000 6000 6000 6000 6000 6000 6000 Actual 12000 4000 6000 15000 10000 4000 6000 5000 3000 2000 1000 4000 a) What is MAD? b) What is standard deviation? c) What is the tracking signal per month? d) The company uses a trigger of +/- 4, which period(s) should the forecast be looked at? e) Reviewing the actual versus forecast for last year, do you agree with Jane and John's Goodie Baskets' forecasting technique? Give your recommendations to improve the Las YouTube Maps !!: Apps d) The company uses a trigger of +/- 4, which period(s) should the forecast be looked at? e) Reviewing the actual versus forecast for last year, do you agree with Jane and John's Goodie Baskets' forecasting technique? Give your recommendations to improve the forecast accuracy. (I am looking for a qualitative recommendation; it does not need to be supported by a revised quantitative forecast.) f) is the error random or bias? g) For Jane and John's Goodie Baskets to maintain their customer service goal above, how much safety stock should they maintain? What are the issues with carrying this level of safety stock given the product they are building? Page 3 of 8 Q3- Jane and John's Goodie Baskets has always used a level production strategy to keep their 10 employees busy throughout the year. There are 50 weeks per year, 17 weeks in Fall and Winter and 16 weeks in Spring Semester. Use the sales forecast you created in Q1 to drive this production plan. (20 marks) a) What is the level production plan # by week, there is no opening inventory or projected closing inventory. (2 marks) ane YouTube Maps !!! Apps crearea in QI to drive this production pian. (zu marks) a) What is the level production plan # by week, there is no opening inventory or projected closing inventory. (2 marks) b) Prepare the following three different production plans and the related costs for Jane and John's Goodie Baskets. Discuss the advantages and disadvantages of all options presented and your final recommendation. Use information presented in the case as part of your analysis. Both quantitative and qualitative analysis should accompany this question. (18 marks) i. Level plan Chase plan Create an alternative plan different than level and chase. Q4- The company sells three basket types currently with the following distribution of sales: 1) Exam Care Package equates to 50% of sales 2) We Miss You equates to 30% of sales 3) Let Them Down Gently (Break up) equates to 20% of sales Disaggregate the level production plan calculated in 3 a) into Master Production Schedule quantities for each end item by week. (Does not have to be in the traditional MPS format just the number and how you got it). (3 marks) **Note- we know there are problems with a level strategy, but that is what we are going to go forward with to complete the project. Company Background Jane and John's Goodie Baskets was a business that catered to university and college students in Southern Ontario that were away at post-secondary school. Jane and John's Goodie Baskets created gift baskets for students that parents, grandparents and friends could send to the students away at school. These unique customized baskets served a unique market niche. Business was growing. Their competitive advantage was response to the customer. They had a very agile operation and could complete orders on short notice. They had 10 people full time who together could do 1300 baskets per week. Their employees were an integral part of Jane and John's Goodie Baskets success, to recognize their commitment employees received quarterly profit-sharing cheques. Flexible work schedules were also encouraged because Jane and John's Goodie Baskets recognized that a motivated, fulfilled employee helped to improve customer relations and in turn their collective success and profitability. These employees enjoyed their work so much that employees did not leave and a "waiting list of sorts was prepared of interested applicants to get a job when one opened. There was not much training required as assembling baskets was pretty easy work and people were trained very quickly. New design ideas came mostly from employees so creativity and an artistic flair were important characteristics for employees. Each employee was paid $14 an hour and benefits added on another 36% for close to a $19/hour wage. Employees could do on average 3.25 baskets per hour. They also had a list of homemakers that were willing to take on making baskets on short notice. Some of ---- people were trained very quickly. New design ideas came mostly from employees so creativity and an artistic flair were important characteristics for employees. Each employee was paid $14 an hour and benefits added on another 36% for close to a $19/hour wage. Employees could do on average 3.25 baskets per hour. They also had a list of homemakers that were willing to take on making baskets on short notice. Some of these homemakers were on the "waiting list" for jobs. They paid these homemakers $6 per basket. Some of the post-secondary schools had approached Jane and John's Goodie Baskets about raising money for relief efforts in the Philippines after the Typhoon Kammuri. They were willing to assemble baskets and the wages they were paid were going to be donated to the Red Cross. They would put a team together on short notice and assemble the baskets in the school gym. They would include a note in each assembled basket about the donation to Red Cross Relief Efforts. They had a newer facility that had 2000 square feet. Of that, 1000 feet was storage space, 500 square feet was office space and 500 square feet was assembly space. The storage space could hold about 7000 baskets. It costs $2 per basket per semester to hold inventory in the warehouse. At times when inventory is higher than 7000, it costs an extra $600 for every 1000 extra baskets to store offsite per semester. The offsite warehouse requires a minimum amount of space to be rented. This means increments of 1000 baskets, as an example 2000 baskets, the cost would be $1200. Jane and John's Goodie Baskets was approaching another year-end. It was time to review what had happened over the past year and set a budget for the next fiscal year. The company had one major product family which was Baskets. Q5- Bill of Material Form (12 marks) a) Prepare a bill of material for each end item. Continue on to prepare a master production schedule by end item for the months of September and October which are both 4-week months. Prepare a Material plan for component parts and include procurement lead-time where applicable. Include crew size required. (9 marks) b) When would the first parts need to be received at Jane and John's Goodie Baskets facility (1 mark)? c) How many people in total would be required for final assembly? Do you see a problem based on the case information? Hint- do not use regular rounding rules here, give me a well thought out answer. (2 marks) 01- Jane and John's Goodie Baskets had been using an averaging forecasting model. They thought they should try something different for next year's forecast. They recognized that sales were increasing and they felt they could apply a trend analysis for the yearly forecast and then applying a seasonal index by semester. The following chart represents the demand history over the last 3 years (The last semester is the sales forecast as the sales figures are not in yet.) Calculate the next year's forecast using trend analysis trend line y= 5200X +56,700 (See if you can get that trend line on excel-bonus of 2 marks). Using the yearly forecast calculate the forecast by semester using seasonal index technique. (5 marks) Fall Winter Spring Year 1 31500 21600 8500 Year 2 35000 23100 9600 Year 3 37000 25000 10000 02- Customer Service is very important to Jane and John's Goodie Baskets. In fact, the target for customer service level is 99%. The following are the sales results to the forecast by month for last year. (11 marks) Period Sept Oct Forecast 6000 6000 Actual 12000 4000 6000 ann Q2- Customer Service is very important to Jane and John's Goodie Baskets. In fact, the target for customer service level is 99%. The following are the sales results to the forecast by month for last year. (11 marks) Period Sept Oct Nov Dec Jan Feb March April May June July August Forecast 6000 6000 6000 6000 6000 6000 6000 6000 6000 6000 6000 6000 Actual 12000 4000 6000 15000 10000 4000 6000 5000 3000 2000 1000 4000 a) What is MAD? b) What is standard deviation? c) What is the tracking signal per month? d) The company uses a trigger of +/- 4, which period(s) should the forecast be looked at? e) Reviewing the actual versus forecast for last year, do you agree with Jane and John's Goodie Baskets' forecasting technique? Give your recommendations to improve the Las YouTube Maps !!: Apps d) The company uses a trigger of +/- 4, which period(s) should the forecast be looked at? e) Reviewing the actual versus forecast for last year, do you agree with Jane and John's Goodie Baskets' forecasting technique? Give your recommendations to improve the forecast accuracy. (I am looking for a qualitative recommendation; it does not need to be supported by a revised quantitative forecast.) f) is the error random or bias? g) For Jane and John's Goodie Baskets to maintain their customer service goal above, how much safety stock should they maintain? What are the issues with carrying this level of safety stock given the product they are building? Page 3 of 8 Q3- Jane and John's Goodie Baskets has always used a level production strategy to keep their 10 employees busy throughout the year. There are 50 weeks per year, 17 weeks in Fall and Winter and 16 weeks in Spring Semester. Use the sales forecast you created in Q1 to drive this production plan. (20 marks) a) What is the level production plan # by week, there is no opening inventory or projected closing inventory. (2 marks) ane YouTube Maps !!! Apps crearea in QI to drive this production pian. (zu marks) a) What is the level production plan # by week, there is no opening inventory or projected closing inventory. (2 marks) b) Prepare the following three different production plans and the related costs for Jane and John's Goodie Baskets. Discuss the advantages and disadvantages of all options presented and your final recommendation. Use information presented in the case as part of your analysis. Both quantitative and qualitative analysis should accompany this question. (18 marks) i. Level plan Chase plan Create an alternative plan different than level and chase. Q4- The company sells three basket types currently with the following distribution of sales: 1) Exam Care Package equates to 50% of sales 2) We Miss You equates to 30% of sales 3) Let Them Down Gently (Break up) equates to 20% of sales Disaggregate the level production plan calculated in 3 a) into Master Production Schedule quantities for each end item by week. (Does not have to be in the traditional MPS format just the number and how you got it). (3 marks) **Note- we know there are problems with a level strategy, but that is what we are going to go forward with to complete the project

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts