Question: Prepare Kaizen step-based improvement plan Map for exm103 Operation (OPN)4 Operator 1 Cycle time (C/T) Line 1 1.5 min Operation (OPN) 1 Operator 1 Cycle

- Prepare Kaizen step-based improvement plan Map for exm103

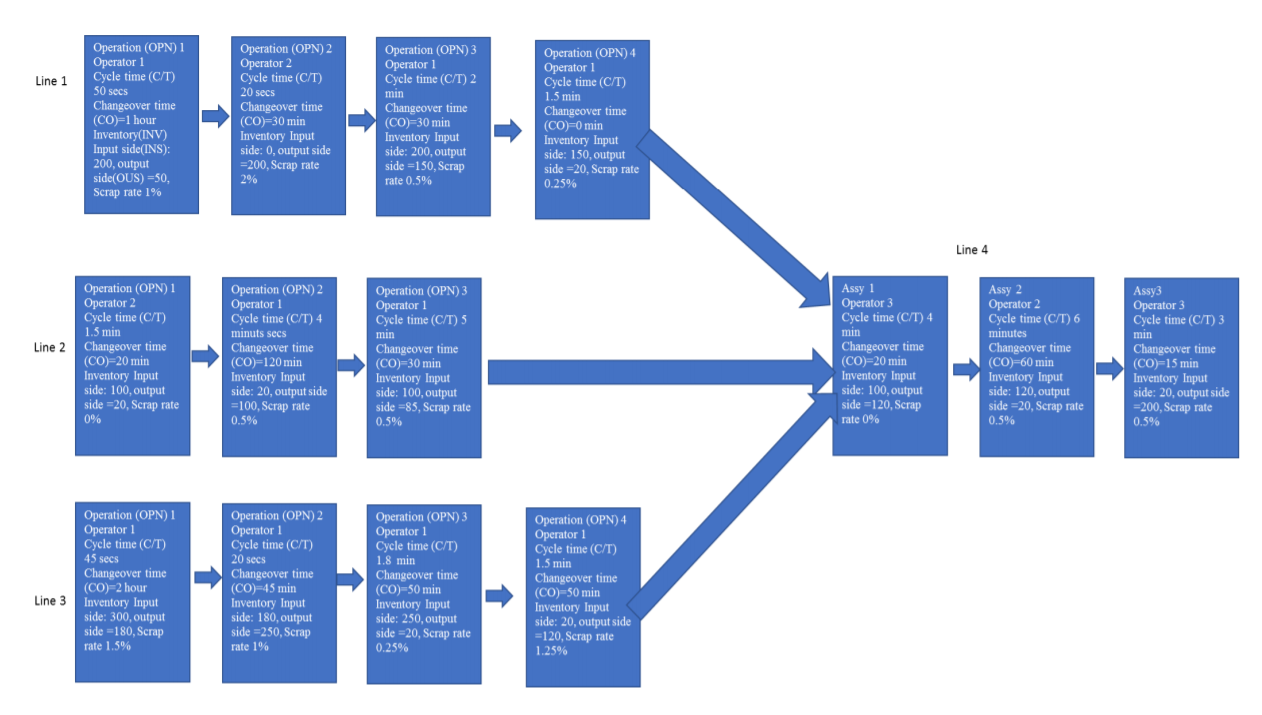

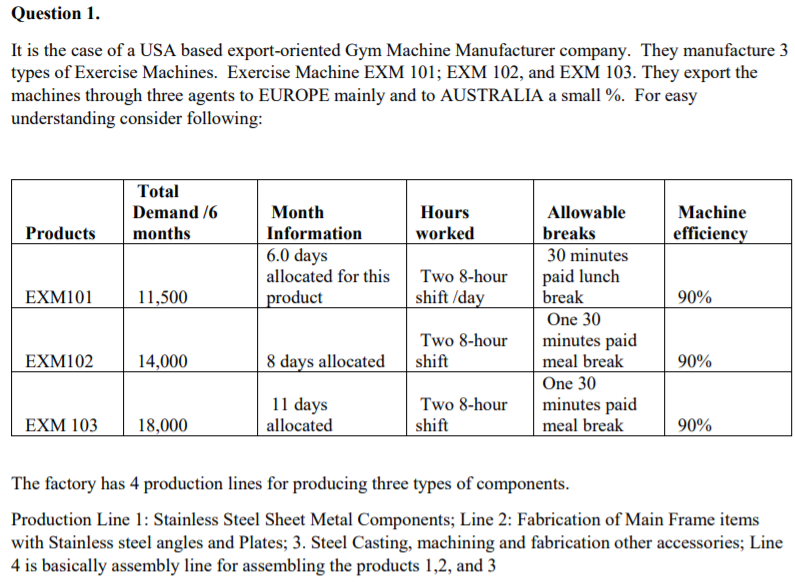

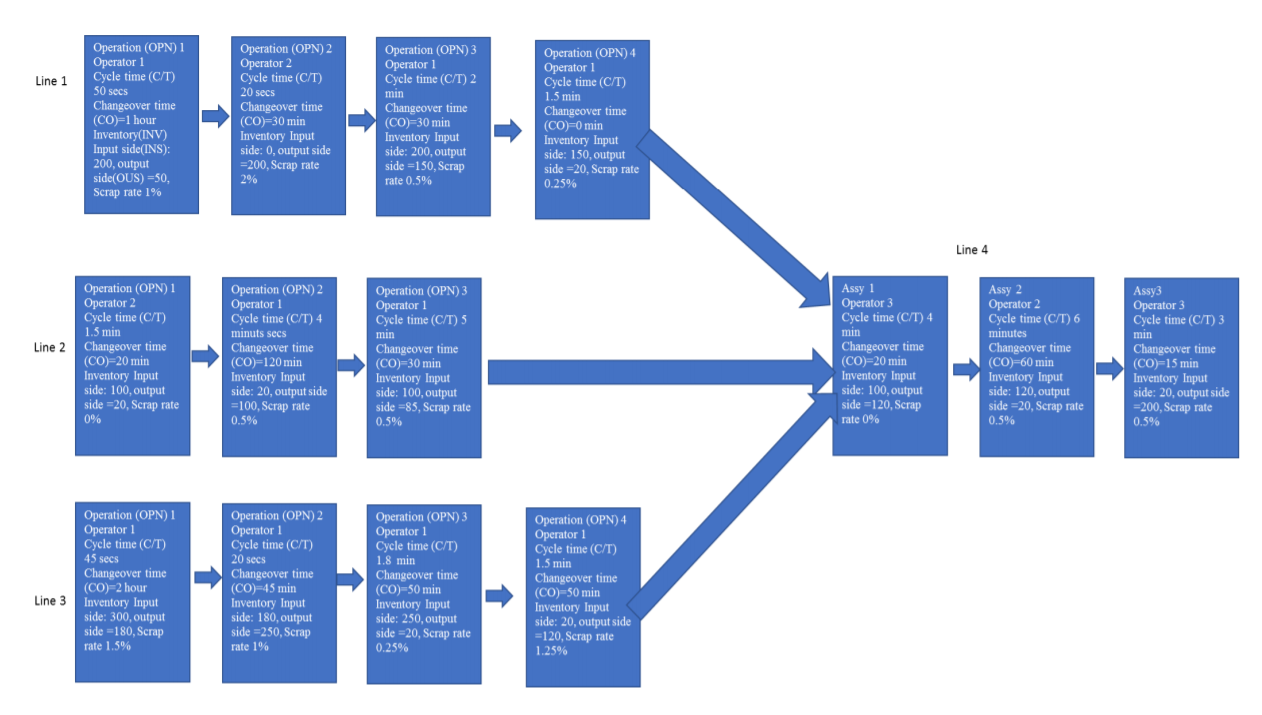

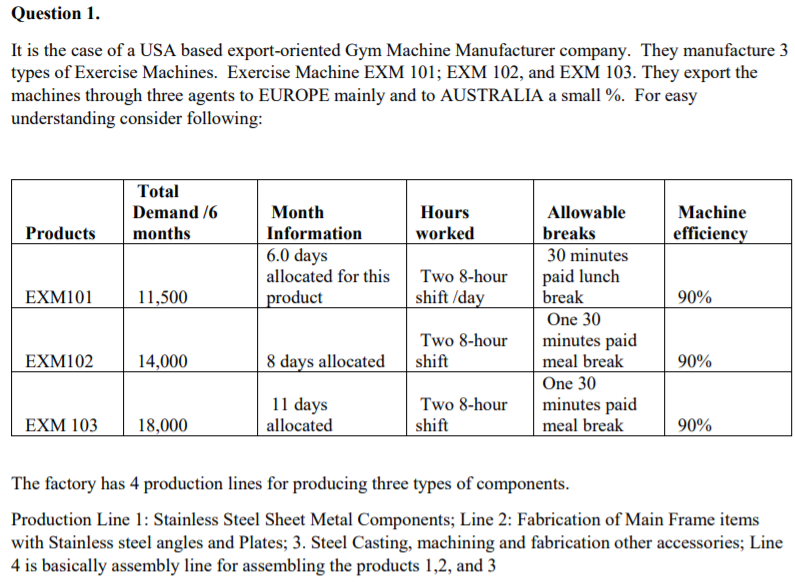

Operation (OPN)4 Operator 1 Cycle time (C/T) Line 1 1.5 min Operation (OPN) 1 Operator 1 Cycle time (C/T) 50 secs Changeover time (CO)=1 hour Inventory(INV) Input side(INS): 200, output side(OUS) =50, Scrap rate 1% Operation (OPN) 2 Operator 2 Cycle time (C/T) 20 secs Changeover time (CO)=30 min Inventory Input side: 0, output side =200, Scrap rate 2% Operation (OPN)3 Operator 1 Cycle time (C/T)2 min Changeover time (CO)=30 min Inventory Input side: 200, output side =150, Scrap rate 0.5% Changeover time (CO)=0 min Inventory Input side: 150, output side =20, Scrap rate 0.25% Line 4 Line 2 Operation (OPN) 1 Operator 2 Cycle time (C/T) 1.5 min Changeover time (CO)=20 min Inventory Input side: 100, output side = 20, Scrap rate 0% Operation (OPN) 2 Operator 1 Cycle time (C/T) 4 minuts secs Changeover time (CO)=120 min Inventory Input side: 20, output side =100, Scrap rate 0.5% Operation (OPN) 3 Operator 1 Cycle time (C/T) 5 min Changeover time (CO)=30 min Inventory Input side: 100, output side =85, Scrap rate 0.5% Assy 1 Operator 3 Cycle time (C/T) 4 min Changeover time (CO)=20 min Inventory Input side: 100, output side =120, Scrap rate 0% Assy 2 Operator 2 Cycle time (C/T) 6 minutes Changeover time (CO)=60 min Inventory Input side: 120, output side =20, Scrap rate 0.5% Assy3 Operator 3 Cycle time (C/T) 3 min Changeover time (CO)=15 min Inventory Input side: 20, output side =200, Scrap rate 0.5% Operation (OPN) 1 Operator 1 Cycle time (C/T) 45 secs Changeover time (CO)=2 hour Inventory Input side: 300, output side =180, Scrap rate 1.5% Operation (OPN) 2 Operator 1 Cycle time (C/T) 20 secs Changeover time (CO)=45 min Inventory Input side: 180, output side =250, Scrap Operation (OPN) 3 Operator 1 Cycle time (C/T) 1.8 min Changeover time (CO)50 min Inventory Input side: 250, output side =20, Scrap rate 0.25% Operation (OPN)4 Operator 1 Cycle time (C/T) 1.5 min Changeover time (CO)=50 min Inventory Input side: 20, output side =120, Scrap rate 1.25% Line 3 rate 1% Question 1. It is the case of a USA based export-oriented Gym Machine Manufacturer company. They manufacture 3 types of Exercise Machines. Exercise Machine EXM 101; EXM 102, and EXM 103. They export the machines through three agents to EUROPE mainly and to AUSTRALIA a small %. For easy understanding consider following: Total Demand /6 months Hours worked Machine efficiency Products Month Information 6.0 days allocated for this product EXM101 11,500 Two 8-hour shift /day 90% Allowable breaks 30 minutes paid lunch break One 30 minutes paid meal break One 30 minutes paid meal break EXM102 14,000 Two 8-hour shift 8 days allocated 90% 11 days allocated Two 8-hour shift EXM 103 18,000 90% The factory has 4 production lines for producing three types of components. Production Line 1: Stainless Steel Sheet Metal Components; Line 2: Fabrication of Main Frame items with Stainless steel angles and Plates; 3. Steel Casting, machining and fabrication other accessories; Line 4 is basically assembly line for assembling the products 1,2, and 3 Operation (OPN)4 Operator 1 Cycle time (C/T) Line 1 1.5 min Operation (OPN) 1 Operator 1 Cycle time (C/T) 50 secs Changeover time (CO)=1 hour Inventory(INV) Input side(INS): 200, output side(OUS) =50, Scrap rate 1% Operation (OPN) 2 Operator 2 Cycle time (C/T) 20 secs Changeover time (CO)=30 min Inventory Input side: 0, output side =200, Scrap rate 2% Operation (OPN)3 Operator 1 Cycle time (C/T)2 min Changeover time (CO)=30 min Inventory Input side: 200, output side =150, Scrap rate 0.5% Changeover time (CO)=0 min Inventory Input side: 150, output side =20, Scrap rate 0.25% Line 4 Line 2 Operation (OPN) 1 Operator 2 Cycle time (C/T) 1.5 min Changeover time (CO)=20 min Inventory Input side: 100, output side = 20, Scrap rate 0% Operation (OPN) 2 Operator 1 Cycle time (C/T) 4 minuts secs Changeover time (CO)=120 min Inventory Input side: 20, output side =100, Scrap rate 0.5% Operation (OPN) 3 Operator 1 Cycle time (C/T) 5 min Changeover time (CO)=30 min Inventory Input side: 100, output side =85, Scrap rate 0.5% Assy 1 Operator 3 Cycle time (C/T) 4 min Changeover time (CO)=20 min Inventory Input side: 100, output side =120, Scrap rate 0% Assy 2 Operator 2 Cycle time (C/T) 6 minutes Changeover time (CO)=60 min Inventory Input side: 120, output side =20, Scrap rate 0.5% Assy3 Operator 3 Cycle time (C/T) 3 min Changeover time (CO)=15 min Inventory Input side: 20, output side =200, Scrap rate 0.5% Operation (OPN) 1 Operator 1 Cycle time (C/T) 45 secs Changeover time (CO)=2 hour Inventory Input side: 300, output side =180, Scrap rate 1.5% Operation (OPN) 2 Operator 1 Cycle time (C/T) 20 secs Changeover time (CO)=45 min Inventory Input side: 180, output side =250, Scrap Operation (OPN) 3 Operator 1 Cycle time (C/T) 1.8 min Changeover time (CO)50 min Inventory Input side: 250, output side =20, Scrap rate 0.25% Operation (OPN)4 Operator 1 Cycle time (C/T) 1.5 min Changeover time (CO)=50 min Inventory Input side: 20, output side =120, Scrap rate 1.25% Line 3 rate 1% Question 1. It is the case of a USA based export-oriented Gym Machine Manufacturer company. They manufacture 3 types of Exercise Machines. Exercise Machine EXM 101; EXM 102, and EXM 103. They export the machines through three agents to EUROPE mainly and to AUSTRALIA a small %. For easy understanding consider following: Total Demand /6 months Hours worked Machine efficiency Products Month Information 6.0 days allocated for this product EXM101 11,500 Two 8-hour shift /day 90% Allowable breaks 30 minutes paid lunch break One 30 minutes paid meal break One 30 minutes paid meal break EXM102 14,000 Two 8-hour shift 8 days allocated 90% 11 days allocated Two 8-hour shift EXM 103 18,000 90% The factory has 4 production lines for producing three types of components. Production Line 1: Stainless Steel Sheet Metal Components; Line 2: Fabrication of Main Frame items with Stainless steel angles and Plates; 3. Steel Casting, machining and fabrication other accessories; Line 4 is basically assembly line for assembling the products 1,2, and 3