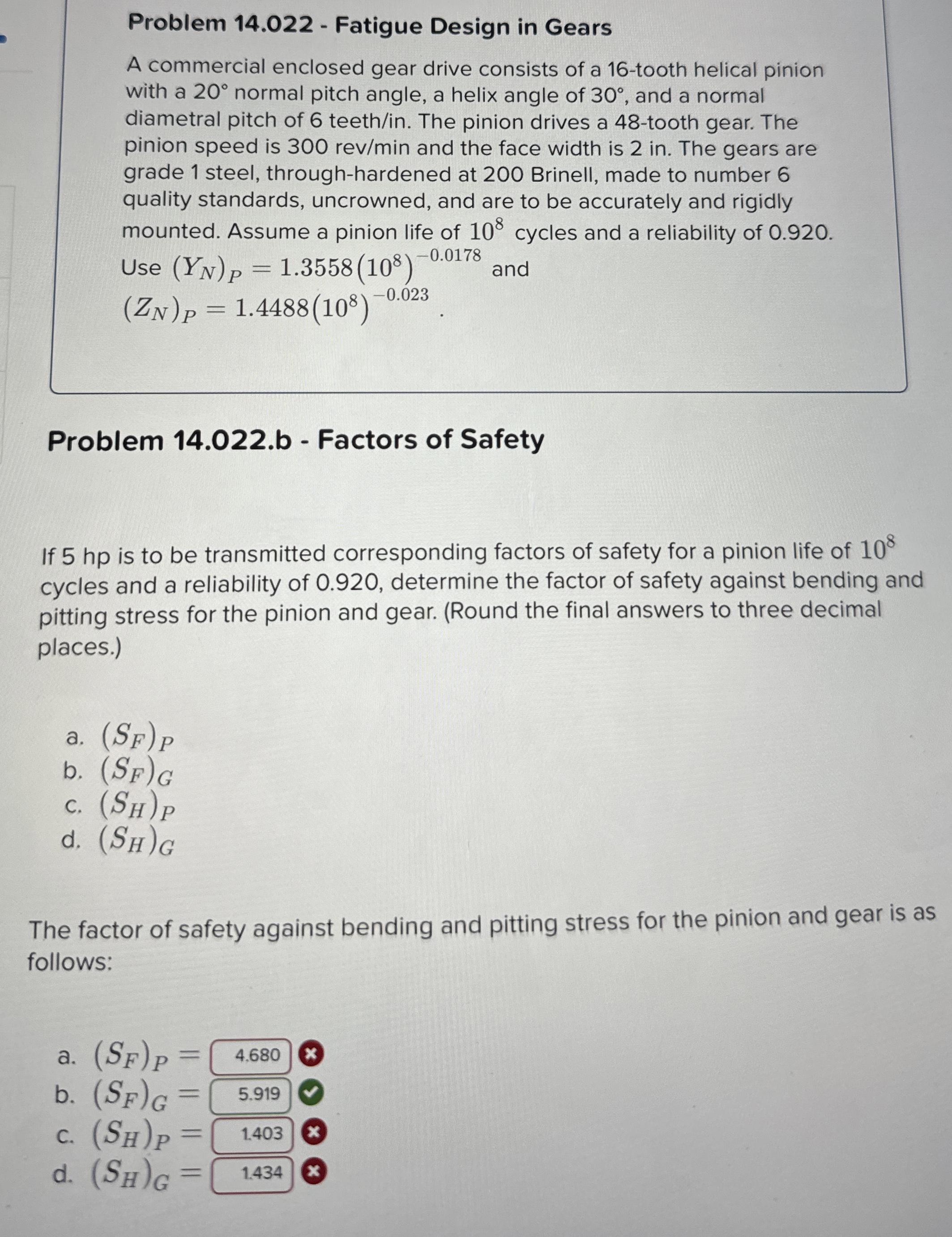

Question: Problem 1 4 . 0 2 2 - Fatigue Design in Gears A commercial enclosed gear drive consists of a 1 6 - tooth helical

Problem Fatigue Design in Gears

A commercial enclosed gear drive consists of a tooth helical pinion

with a normal pitch angle, a helix angle of and a normal

diametral pitch of teeth The pinion drives a tooth gear. The

pinion speed is and the face width is in The gears are

grade steel, throughhardened at Brinell, made to number

quality standards, uncrowned, and are to be accurately and rigidly

mounted. Assume a pinion life of cycles and a reliability of

Use and

Problem b Factors of Safety

If hp is to be transmitted corresponding factors of safety for a pinion life of

cycles and a reliability of determine the factor of safety against bending and

pitting stress for the pinion and gear. Round the final answers to three decimal

places.

a

b

c

d

The factor of safety against bending and pitting stress for the pinion and gear is as

follows:

a

b

c

d

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock