Question: Problem 1 : Emma's Precision Tooling has a contract for 1 2 0 , 0 0 0 units of a specialized component. Emma Thompson, the

Problem :

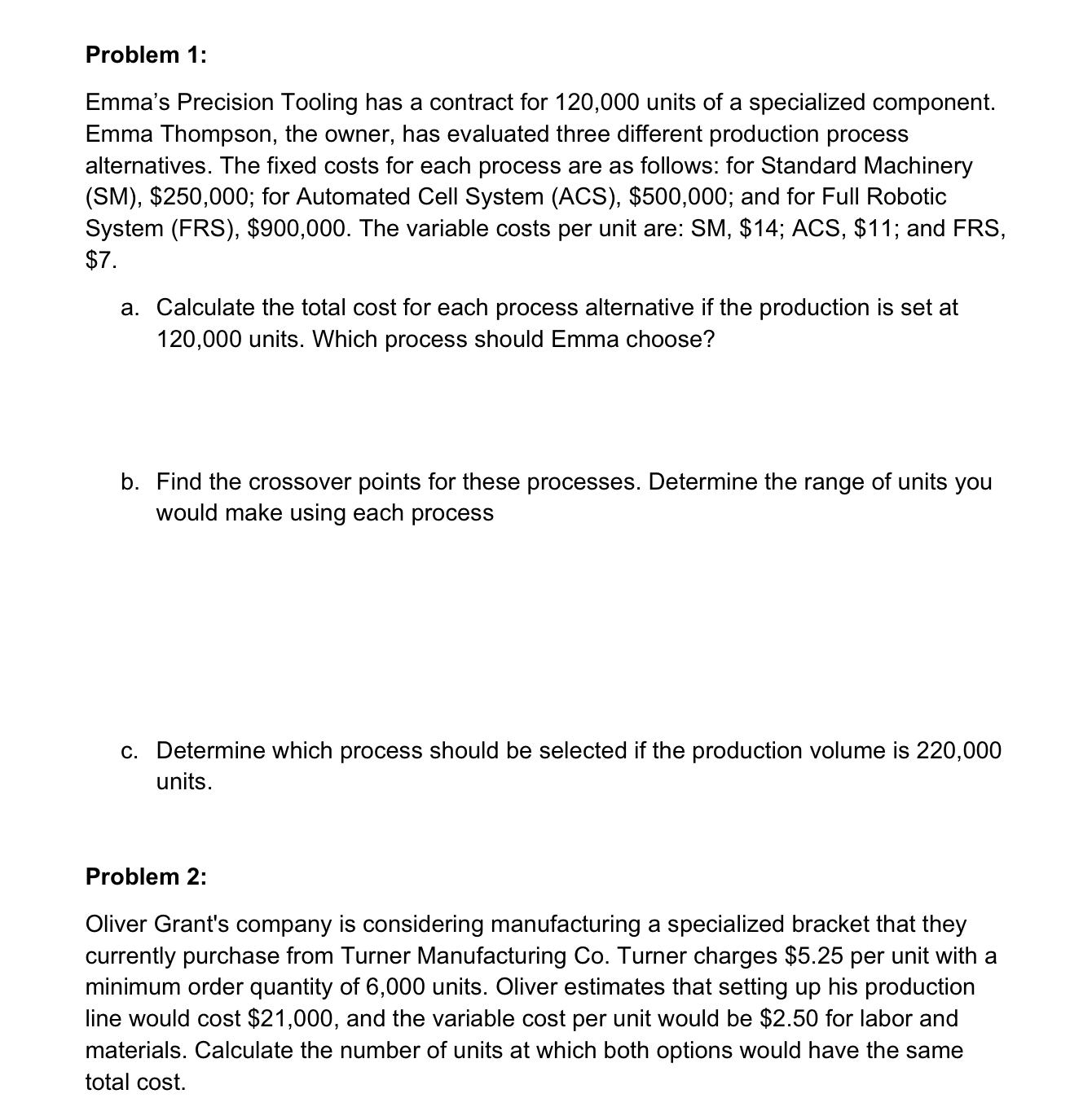

Emma's Precision Tooling has a contract for units of a specialized component. Emma Thompson, the owner, has evaluated three different production process alternatives. The fixed costs for each process are as follows: for Standard Machinery SM $; for Automated Cell System ACS $; and for Full Robotic System FRS $ The variable costs per unit are: SM $; ACS, $; and FRS $

a Calculate the total cost for each process alternative if the production is set at units. Which process should Emma choose?

b Find the crossover points for these processes. Determine the range of units you would make using each process

c Determine which process should be selected if the production volume is units.

Problem :

Oliver Grant's company is considering manufacturing a specialized bracket that they currently purchase from Turner Manufacturing Co Turner charges $ per unit with a minimum order quantity of units. Oliver estimates that setting up his production line would cost $ and the variable cost per unit would be $ for labor and materials. Calculate the number of units at which both options would have the same total cost.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock