Question: PROBLEM #2 (JIT in inventory control and delivery to customers) A JIT and Industrial Engineering team have set a target to eliminate waist in storage

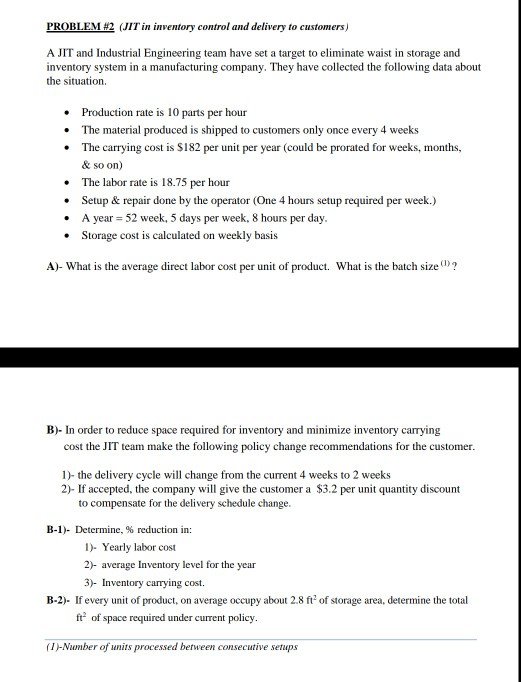

PROBLEM #2 (JIT in inventory control and delivery to customers) A JIT and Industrial Engineering team have set a target to eliminate waist in storage and inventory system in a manufacturing company. They have collected the following data about the situation .Production rate is 10 parts per hour The material produced is shipped to customers only once every 4 weeks The carrying cost is $182 per unit per year (could be prorated for weeks, months, & so on) The labor rate is 18.75 per hour Setup & repair done by the operator (One 4 hours setup required per week.) A year 52 week, 5 days per week, 8 hours per day Storage cost is calculated on weekly basis . . A)- What is the average direct labor cost per unit of product. What is the batch size? B)- In order to reduce space required for inventory and minimize inventory carrying cost the JIT team make the following policy change recommendations for the customer. 1) the delivery cycle will change from the current 4 weeks to 2 weeks 2)- If accepted, the company will give the customer a $3.2 per unit quantity discount to compensate for the delivery schedule change. B-1)-Determine, % reduction in: 1)- Yearly labor cost 2)- average Inventory level for the year 3) Inventory carrying cost. If every unit of product, on average occupy about 2.8 ft2 of storage area, determine the total ft2 of B-2). space required under current policy ( 1 )-Number of units processed between consecutive setups

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts