Question: Problem #2 (problem #18 in chapter 3) Davison Electronics manufactures two LCD television monitors, identified as model A and model B. Each model has its

Problem #2 (problem #18 in chapter 3)

Davison Electronics manufactures two LCD television monitors, identified as model A and model B. Each model has its lowest possible production cost when produced on Davisons new production line. However, the new production line does not have the capacity to handle the total production of both models. As a result, at least some of the production must be routed to a higher-cost, old production line. The following table shows the minimum production requirements for next month, the production line capacities in units per month, and the production cost per unit for each production line:

| Production Cost per Unit | Minimum Production Requirements | ||

| Model | New Line | Old Line | |

| A | $30 | $50 | 50,000 |

| B | $25 | $40 | 70,000 |

| Production Line Capacity | 80,000 | 60,000 | |

Let

AN = Units of model A produced on the new production line

AO = Units of model A produced on the old production line

BN = Units of model B produced on the new production line

BO = Units of model B produced on the old production line

To determine the minimum cost production plan, the company developed the following LP: Min 30AN + 50AO + 25BN + 40BO

s.t.

(Minimum production for model A) AN + AO 50,000

(Minimum production for model B) BN + BO 70,000

(Capacity of New Product Line) AN + BN 80,000

(Capacity of Old Product Line) AO + BO 60,000

(Non-negativity) AN, AO BN, BO > 0

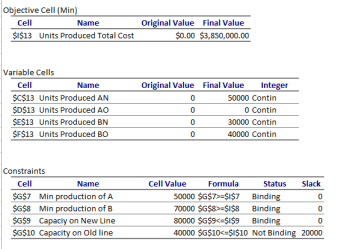

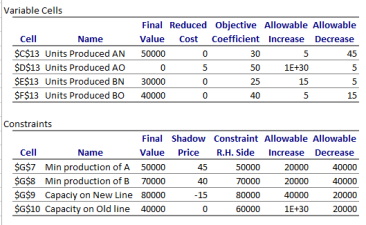

The Excel output (answer and sensitivity reports) are shown below.

Use the above answer and sensitivity reports to answer the following questions

(a) What is the optimal solution, and what is the total production cost associated with this solution?

(b) Which constraints are binding? Explain.

(c) The production manager noted that the only constraint with a negative shadow price is the constraint on the capacity of the new production line. The managers interpretation of the shadow price was that a one-unit increase in the right-hand side of this constraint would actually increase the total production cost by $15 per unit. Do you agree with this interpretation? Would an increase in capacity for the new production line be desirable? Explain.

(d) Would you recommend increasing the capacity of the old production line? Explain.

(e) Suppose that the minimum production requirement for model B is reduced from 70,000 units to 60,000 units. What effect would this change have on the total production cost? Explain

Objective Cell (Min) Cell Name $1$13 Units Produced Total Cost Original Value Final Value $0.00 $3,850,000.00 Variable Cells Cell Name $C$13 Units Produced AN $D$13 Units Produced AO $E$13 Units Produced BN $F$13 Units Produced BO Original Value Final Value Integer 0 50000 Contin 0 O Contin 0 30000 Contin 0 40000 Contin Constraints Cell Name $G$7 Min production of A $G$8 Min production of B $G$9 Capacly on New Line $6$10 Capacity on Old line Cell Value Formula Status Slack 50000 $G$7>=$i$7 Binding 0 70000 $G$8>=$1$8 Binding 0 80000 $G$9$1$9 Binding 0 40000 $G$10$$10 Not Binding 20000 Variable Cells Cell Name $C$13 Units Produced AN $D$13 Units Produced AO $E$13 Units Produced BN $F$13 Units Produced BO Final Reduced Objective Allowable Allowable Value Cost Coefficient Increase Decrease 50000 0 30 5 45 0 5 50 1E+30 5 30000 0 0 25 15 5 40000 0 40 5 15 Constraints Final Shadow Constraint Allowable Allowable Cell Name Value Price R.H. Side Increase Decrease $G$7 Min production of A 50000 45 50000 20000 40000 $G$8 Min production of B 70000 70000 20000 40000 $G$9 Capacly on New Line 80000 -15 80000 40000 20000 $G$10 Capacity on Old line 40000 0 60000 1E+30 20000 40Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts