Question: Problem #2: Warehouse Consider an online retailer that operates a 100,000 square foot warehouse. The warehouse is automated such that robots fetch items from

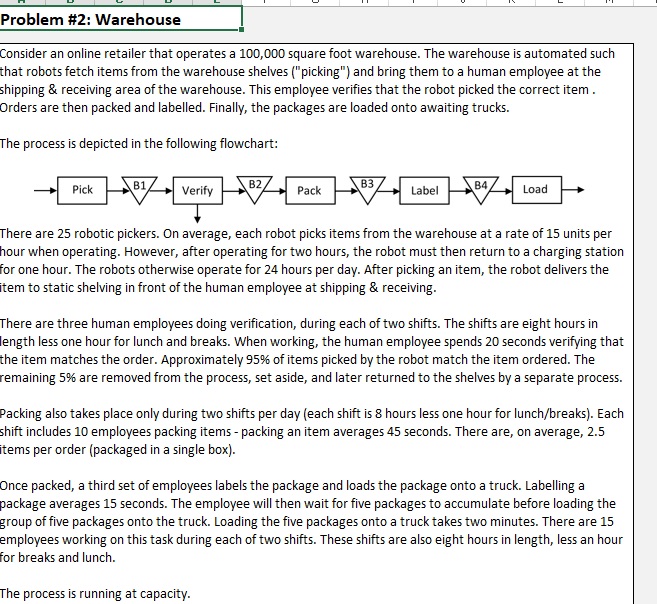

Problem #2: Warehouse Consider an online retailer that operates a 100,000 square foot warehouse. The warehouse is automated such that robots fetch items from the warehouse shelves ("picking") and bring them to a human employee at the shipping & receiving area of the warehouse. This employee verifies that the robot picked the correct item. Orders are then packed and labelled. Finally, the packages are loaded onto awaiting trucks. The process is depicted in the following flowchart: Pick B1 Verify B2 B3 B4, Pack Label Load There are 25 robotic pickers. On average, each robot picks items from the warehouse at a rate of 15 units per hour when operating. However, after operating for two hours, the robot must then return to a charging station for one hour. The robots otherwise operate for 24 hours per day. After picking an item, the robot delivers the item to static shelving in front of the human employee at shipping & receiving. There are three human employees doing verification, during each of two shifts. The shifts are eight hours in length less one hour for lunch and breaks. When working, the human employee spends 20 seconds verifying that the item matches the order. Approximately 95% of items picked by the robot match the item ordered. The remaining 5% are removed from the process, set aside, and later returned to the shelves by a separate process. Packing also takes place only during two shifts per day (each shift is 8 hours less one hour for lunch/breaks). Each shift includes 10 employees packing items - packing an item averages 45 seconds. There are, on average, 2.5 items per order (packaged in a single box). Once packed, a third set of employees labels the package and loads the package onto a truck. Labelling a package averages 15 seconds. The employee will then wait for five packages to accumulate before loading the group of five packages onto the truck. Loading the five packages onto a truck takes two minutes. There are 15 employees working on this task during each of two shifts. These shifts are also eight hours in length, less an hour for breaks and lunch. The process is running at capacity. a) What is the capacity of this system in items/day. units per day b) Suppose that the second shift of humans leaves the warehouse at midnight and the robot pickers continue working. How many items are sitting in the buffer B1 by the time the first shift of humans return on the next day at 8:00 AM? units c) What is the average inventory level in the buffer preceding verification over the course of an entire 24-hr day? units d) On average, how long does an item spend waiting in the buffer preceding verification, in hours? hours e) What is the average flowtime of an item (including both rejected items and items that verified and continue through the system to completion)? hours f) What is the utilization of the human employees doing packing? %

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts