Question: Problem 3: Maintenance Shop Operation Q40 marks! You operate a maintenance shop that repairs aircraft engine compressors for a large airline. The number of compressors

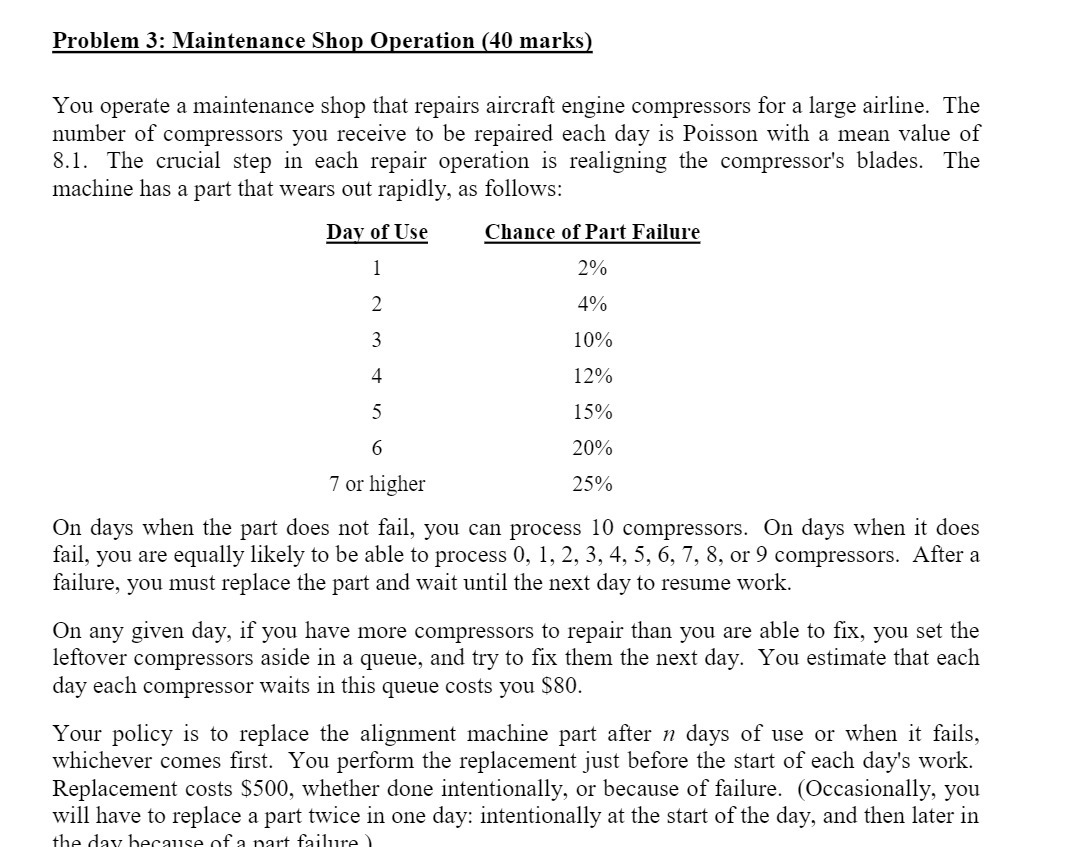

Problem 3: Maintenance Shop Operation Q40 marks! You operate a maintenance shop that repairs aircraft engine compressors for a large airline. The number of compressors you receive to be repaired each day is Poisson with a mean value of 8.1. The crucial step in each repair operation is realigning the compressor's blades. The machine has a part that wears out rapidly, as follows: Day of Use Chance of Part Failure 1 2% 2 4% 3 10% 4 12% 5 15% 6 20% 7 or higher 25% On days when the part does not fail, you can process 10 compressors. On days when it does fail, you are equally likely to be able to process 0, l, 2, 3, 4, 5, 6, 7, 8, or 9 compressors. After a failure, you must replace the part and wait until the next day to resume work. On any given day, if you have more compressors to repair than you are able to fix, you set the leftover compressors aside in a queue, and try to fix them the next day. You estimate that each day each compressor waits in this queue costs you $80. Your policy is to replace the alignment machine part after 3? days of use or when it fails, whichever comes first. You perform the replacement just before the start of each day's work. Replacement costs $500, whether done intentionally, or because of failure. (Occasionally, you will have to replace a part twice in one day: intentionally at the start of the day, and then later in flat: tint: lpr'nnop rue-a nnrt Fail'nrp l

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts