Question: Problem 5 ( 1 0 pts ) In the final inspection of a clock radio production, the Quality Control and Improvement Team tallied the number

Problem pts

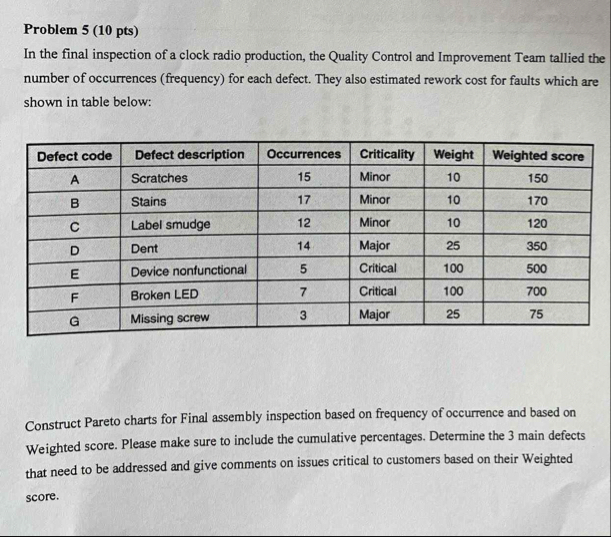

In the final inspection of a clock radio production, the Quality Control and Improvement Team tallied the number of occurrences frequency for each defect. They also estimated rework cost for faults which are shown in table below:

tableDefect code,Defect description,Occurrences,Criticality,Weight,Weighted scoreAScratches,Minor,BStains,Minor,CLabel smudge,Minor,DDent,Major,EDevice nonfunctional,Critical,FBroken LED,Critical,GMissing screw,Major,

Construct Pareto charts for Final assembly inspection based on frequency of occurrence and based on Weighted score. Please make sure to include the cumulative percentages. Determine the main defects that need to be addressed and give comments on issues critical to customers based on their Weighted score.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock