Question: Problem 6 ( 2 5 points ) In a dairy plant, milk at 4 C is pasteurized continuously at 7 2 C at a rate

Problem points

In a dairy plant, milk at is pasteurized continuously at at a rate of liters per minute for hours per day and days a year. The milk is heated to the pasteurizing temperature by hot process water generated by a natural gas fired boiler. The pasteurized milk is then cooled from back to by chilled water.

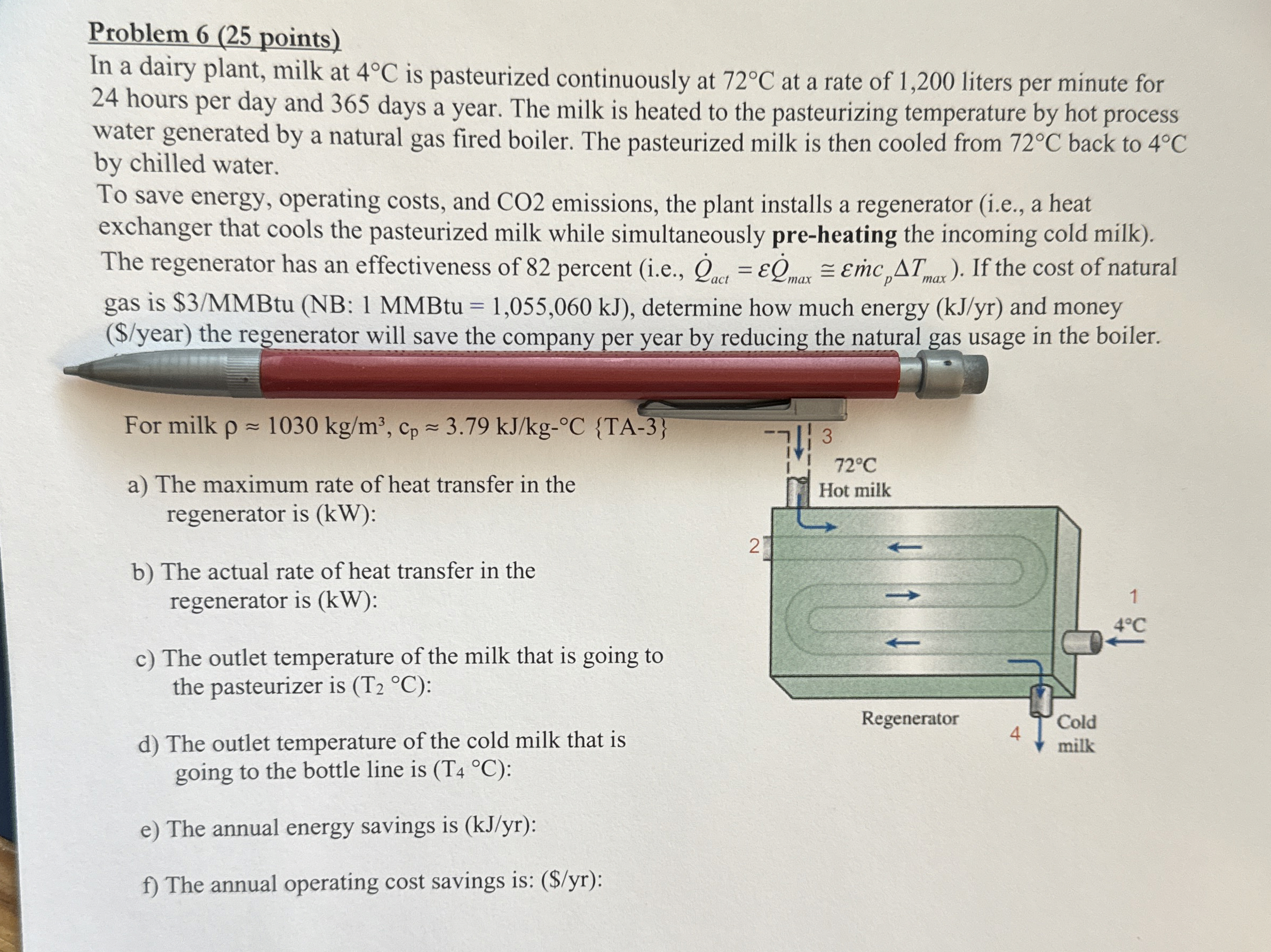

To save energy, operating costs, and CO emissions, the plant installs a regenerator ie a heat exchanger that cools the pasteurized milk while simultaneously preheating the incoming cold milk The regenerator has an effectiveness of percent ie~ If the cost of natural gas is determine how much energy and money $year the regenerator will save the company per year by reducing the natural gas usage in the boiler.

For milk ~~~~

a The maximum rate of heat transfer in the regenerator is :

b The actual rate of heat transfer in the regenerator is :

c The outlet temperature of the milk that is going to the pasteurizer is :

d The outlet temperature of the cold milk that is going to the bottle line is :

e The annual energy savings is :

f The annual operating cost savings is: :

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock