Question: Problem: A 20 station automatic assembly line operates 350 days per year on a two-shift basis. The line is stopped upon demand for machine repair

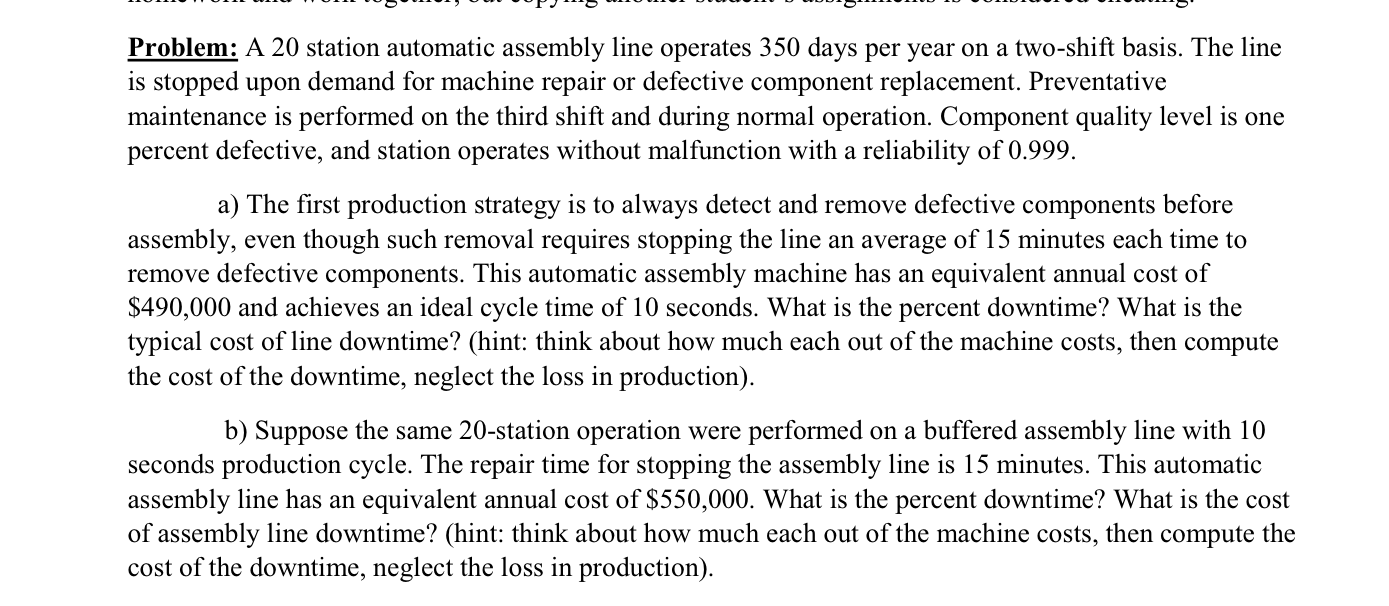

Problem: A 20 station automatic assembly line operates 350 days per year on a two-shift basis. The line is stopped upon demand for machine repair or defective component replacement. Preventative maintenance is performed on the third shift and during normal operation. Component quality level is one percent defective, and station operates without malfunction with a reliability of 0.999 . a) The first production strategy is to always detect and remove defective components before assembly, even though such removal requires stopping the line an average of 15 minutes each time to remove defective components. This automatic assembly machine has an equivalent annual cost of $490,000 and achieves an ideal cycle time of 10 seconds. What is the percent downtime? What is the typical cost of line downtime? (hint: think about how much each out of the machine costs, then compute the cost of the downtime, neglect the loss in production). b) Suppose the same 20-station operation were performed on a buffered assembly line with 10 seconds production cycle. The repair time for stopping the assembly line is 15 minutes. This automatic assembly line has an equivalent annual cost of $550,000. What is the percent downtime? What is the cost of assembly line downtime? (hint: think about how much each out of the machine costs, then compute the cost of the downtime, neglect the loss in production)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts