Question: Problem Statement: Design of a Gearbox for a Conveyor System Your team is tasked with designing a gearbox for an industrial conveyor system. The conveyor

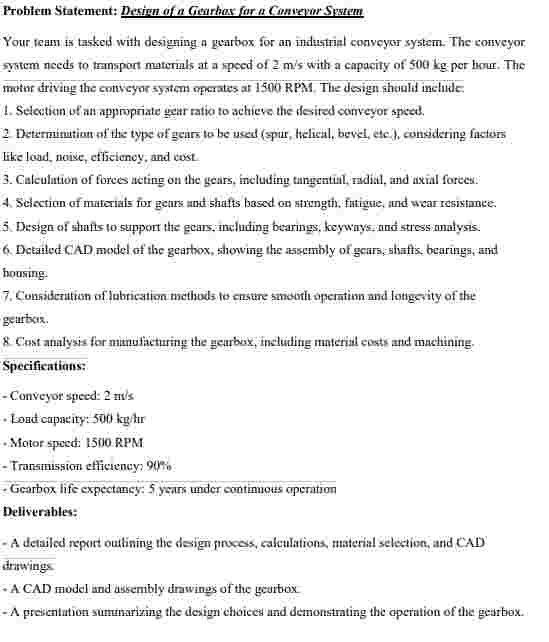

Problem Statement: Design of a Gearbox for a Conveyor System

Your team is tasked with designing a gearbox for an industrial conveyor system. The conveyor system needs to transport materials at a speed of ms with a capacity of kg per hour. The motor driving the conveyor system operates at RPM The design should include:

Selection of an appropriate gear ratio to achieve the desired conveyor speed.

Determination of the type of gears to be used spur helical, bevel, etc. considering factors like load, noise, efficiency, and cost.

Calculation of forces acting on the gears, including tangential radial, and axial forces.

Selection of materials for gears and shafts based on strength, fatigue, and wear resistance.

Design of shafts to support the gears, including bearings, keyways, and stress analysis.

Detailed CAD model of the gearbox, showing the assembly of gears, shafts, bearings, and housing.

Consideration of lubrication methods to ensure smooth operation and longevity of the gearbox.

Cost analysis for manufacturing the gearbox, including material costs and machining.

Specifications:

Conveyor speed: ms

Load capacity: kghr

Motor speed: RPM

Transmission efficiency:

Gearbox life expectancy: years under continuous operation Deliverables:

A detailed report outlining the design process, calculations, material selection, and CAD drawings.

A CAD model and assembly drawings of the gearbox.

A presentation summarizing the design choices and demonstrating the operation of the gearbox

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock