Question: Students will complete case study 7-2 Caledon Concrete Mixers (from textbook) including: 1. Executive Summary 2. Problem Statement 3. Problem Analysis 4. Alternatives 5. Recommended

Students will complete case study 7-2 Caledon Concrete Mixers (from textbook) including:

Students will complete case study 7-2 Caledon Concrete Mixers (from textbook) including:

1. Executive Summary

2. Problem Statement

3. Problem Analysis

4. Alternatives

5. Recommended Solution (including justification)

6. Implementation Plan

7. Conclusion

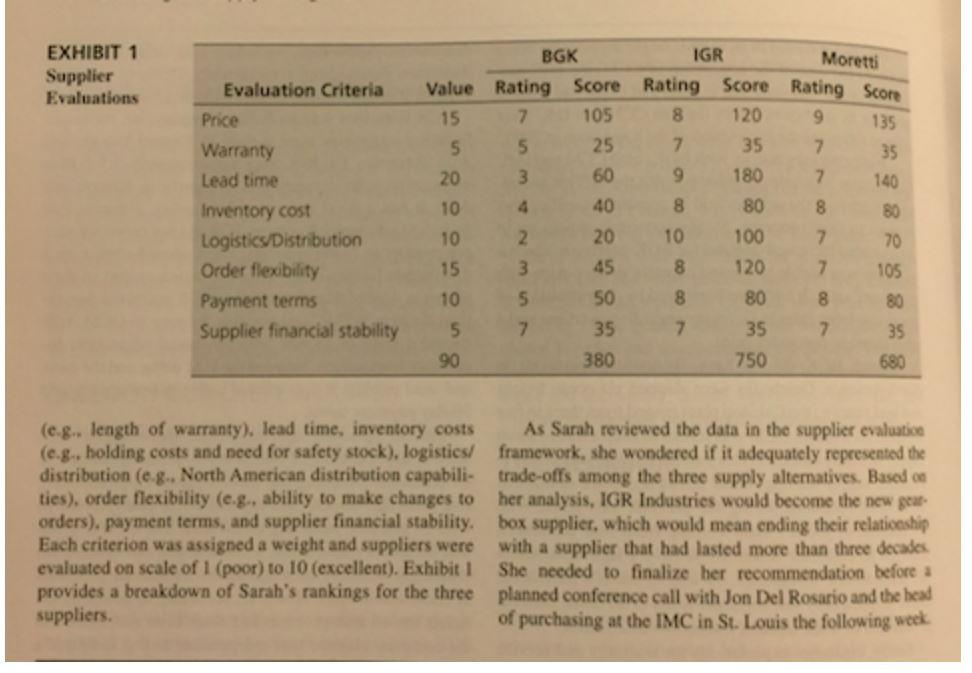

Case 7-2 Caledon Concrete Mixers was in supply, where combining purchases between the two operations for some products had yielded significant savings Jon Del Rosario, purchasing manager in the corporate par chasing group in Chicago, was responsible for coordinating purchasing between the Caledon and St. Louis plants. As Sarah Jenkins, materials manager at Caledon Concrete Mixers, ended her conference call with Jon Del Rosario from corporate purchasing, she wondered what recommen- dations she should make regarding the selection of a gearbox supplier. The corporate purchasing group in Chicago was advocating switching to a new supplier, but Sarah remained concerned about the risks of ending a long-term supply ar- rangement with a key supplier. It was now December the 3rd and she wanted to make a final recommendation before the plant shut down for the annual Christmas holiday break. Sarah Jenkins was responsible for materials manage ment at CCM. An MBA graduate from the Ivey Business School, Sarah had worked at CCM for more than 20 years Reporting to the general manager, her responsibilities in cluded logistics and transportation, purchasing, inventory control, and production planning. Her counterparts in fi- nance and accounting, quality, operations, sales, HR, and engineering rounded out the senior management team. CALEDON CONCRETE MIXERS THE GEARBOX Located north of Toronto, Canada, in Caledon, Ontario, Caledon Concrete Mixers (CCM) was a manufacturer of truck-mounted concrete mixers. Founded in 1910, the company employed 140 people in its 150,000 square foot plant, including 100 unionized hourly workers, and had annual sales of approximately $25 million. Nearly 40 per- cent of company sales were exported, mainly to the United States. While the concrete mixer truck was in operation, it was necessary to continuously rotate the load to prepare the concrete and avoid consolidation. The gearbox was locat ed at the bottom of the large mixing drum and was used to transmit torque from the hydraulic motor drive shaft, which rotated the drum. The gearbox also permitted the operator to adjust the speed and direction of the rotation. CCM had a strong reputation for quality and service in the industry. It operated as a private business until 2003, when it was purchased by Illinois Machinery Corporation (IMC). IMC was a global manufacturer and marketer of access equipment, specialty vehicles, and truck bodies for the defense, concrete placement, refuse hauling, and fire and emergency markets. Annual revenues in the most current fiscal year were $9 billion and IMC had approxi- mately 18,000 employees. The gearbox was one of approximately 150 compo nents that CCM used for the assembly of their concrete mixers. The gearbox used by CCM came in two varia- tions, depending on the model of the concrete mixer. Each gearbox cost approximately $3,600 and volumes at CCM ranged from 950 to 1.100 units per year. CURRENT SUPPLY ARRANGEMENT Concrete mixer transport trucks were designed to mix concrete and haul it to the construction site. Customers typically specified the truck model, which was ordered from the original equipment manufacturer. CCM fitted the vehicle with the concrete mixing equipment, which includ- ed a large drum and discharge system. Systems were cus- tomized based on vehicle size (e.g., 2-6 axles), discharge system (front or rear), and capacity (maximum capacity to carry 14 cubic yards of payload). CCM and the St. Louis operation both used BGK GmbH as the single source for gearboxes. BGK was a large diver- sified German manufacturing company with annual rev produced gearboxes for industrial applications in a wide enues of 12 billion euros. The division that supplied CCM range of industries, such as material handling equipment. IMC had an operation in St. Louis that manufactured a quality and reliability, although its products were typically energy, and mining. The company had a reputation for high more expensive than those of their competitors. similar product line to CCM under a different brand name, with annual revenues approximately double the Canadian plant. Although IMC operated under a decentralized model, CCM and the St. Louis operation cooperated in areas of engi- neering, purchasing, and sales, while operating autonomously with separate leadership teams. One key area for synergies The relationship with CCM and BGK dated back more than 30 years. BGK offered a standard one-year warranty on experienced any notable quality problems and customers its gearboxes, but Sarah was not aware that CCM had ever were generally satisfied with performance of the product. Chapter 7 Quality 195 IMC had also used BGK as their single supplier for many distribution capabilities, including lead times and North years. At the time of the acquisition of CCM, the IMC por chasing group was surprised to leam that CCM had a better price for its gearboxes Prices for both CCM and IMC were aligned following the completion of the acquisition in 2003. American warehousing arrangements. Delivery would be FOB the London and St. Louis facilities Despite the long history with BGK, both CCM and IMC had become increasingly unhappy with the service and re- sponsiveness of the supplier and its apparent unwillingness to react to their concerns. Strong economic expansion in Asia created increased demand for BGK gearboxes and the company was unable to expand capacity to keep pace with increasing sales. It had been hampered by a combination of restrictive labor rules in Germany regarding overtime and a steel shortage two years prior. IGR Industries was an Italian company, but its mana facturing operations were mainly in Eastern Europe and Asia Revenues for 1GR were approximately 1.5 billion euros, with sales concentrated primarily in Europe and Asia. It had a good reputation for quality, claiming that ply product to North America, but proposed setting up a its failure rate was 10 percent. IGR did distribution facility in the Missouri region as part of their currently sup proposal. Under this arrangement. IGR promised just-in- time delivery to IMC and two-day delivery to CCM. IGR currency fluctuations, between the US dollar and the euro, quoted a price of $3,400, with an annual adjustment for and steel pricing. It also offered a five-year warranty and 30-day payment terms Second, BGK did not have distribution operations in North America. Gearboxes were shipped via ocean freight and lead times to the Caledon plant ranged from three to five months. As a result, CCM was forced to keep a three-month supply of safety stock inventory on hand. Even with this pre-sales of approximately 1 billion euros. It had operations in Moretti SpA was also an Italian manufacturer with castion, supply shortages had threatened plant shutdowns on several occasions during the previous two years. With 50 percent of CCM's sales coming from four customers. changes in customer orders could have a significant effect on demand and inventories. To add to Sarah's frustration, BGK shipped only full container loads of 50 units, whereas production in some months was as low as 20 units Lastly, customer expectations for warranty and service were increasing, yet BGK was unwilling to extend its war- tasty coverage without an increase in price. The supplier referenced its quality data, which boasted the lowest fail- we rate in the industry at 0.5 percent. However, as margins on CCM's products shrank and customer demands grew, Sarah and her peers in the purchasing organization at IMC had become frustrated by the lack of responsiveness from their supplier and decided to test the marketplace. 18 countries, including the United States. Approximately five years ago Moretti had experienced a quality problem with its gearbox, involving an oil leak. The oil leak prob- lem became a major issoe, as contractors had become in- creasingly sensitive to potential environmental problems at construction sites. However, according to company of ficials the oil leak problem had since been addressed and the company claimed that independent testing indicated a defect rate of 1.5 percent of its product after three years of operation. Moretti quoted a price of $3.200, with an an- nual adjustment for currency fluctuations between the U.S. dollar and the euro. The company also offered a five-year warranty and a consignment inventory arrangement. Under the consignment inventory system, Moretti would own the inventory at CCM and IMC until the gearboxes were as sembled into the vehicle, at which point an invoice would be issued, with a 30-day payment term. SUPPLY OPTIONS BGK's proposal was to extend the current supply an rangement, included a price of $3,600 that was sub- The decision was made in September to solicit RFQs for led the RFQ process and identified five potential suppliers, be combined gearbox volumes of CCM and IMC. Sarah ndading BGK, two of which were not invited to partici- ject to annual adjustments and a standard one-year war ranty. Lennart Wagner, the sales representative for BGK indicated that the company was not prepared to set up a North American distribution facility. He to that BGK was the world leader in gearboxes, and the high Asa The two new firms asked to participate were Moretti quality of their product should represent a significant sell- Sind IGR Industries. ing feature of CCM's concrete mixers. The RFQ specified a five-year contract for 100 percent e of 2800 to 3300 units per year. Each supplier was CCM and IMC, representing an annual vol- THE SUPPLIER SELECTION DECISION sabev Wong for the term of the contract, warranty terms, and quotes in U.S. funds that included stable Sarah had developed a supplier evaluation framework that ranked each supplier in eight areas: price, warranty EXHIBIT 1 Supplier Evaluations Evaluation Criteria BGK IGR Moretti Value Rating Score Rating Score Rating Score 15 7 105 8 120 9 135 5 5 25 7 35 7 20 3 60 9 180 10 4 40 8 80 10 2 20 10 100 15 3 45 8 120 7 10 5 50 8 80 8 5 7 35 7 35 7 35 380 750 680 As Sarah reviewed the data in the supplier evaluation framework, she wondered if it adequately represented the trade-offs among the three supply alternatives. Based on her analysis, IGR Industries would become the new gear- box supplier, which would mean ending their relationship with a supplier that had lasted more than three decades. She needed to finalize her recommendation before a planned conference call with Jon Del Rosario and the head of purchasing at the IMC in St. Louis the following week. Price Warranty Lead time Inventory cost Logistics/Distribution Order flexibility Payment terms Supplier financial stability 90 (e.g., length of warranty), lead time, inventory costs (e.g., holding costs and need for safety stock), logistics/ distribution (e.g., North American distribution capabili- ties), order flexibility (e.g., ability to make changes to orders), payment terms, and supplier financial stability. Each criterion was assigned a weight and suppliers were evaluated on scale of 1 (poor) to 10 (excellent). Exhibit 1 provides a breakdown of Sarah's rankings for the three suppliers. 7 8 7 35 140 80 70 105 80Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts