Question: Process Analysis - Putting the Pieces Together: Billy Bob Cookies Billy and Bob are really excited about their new venture. Having discussed a cookie company

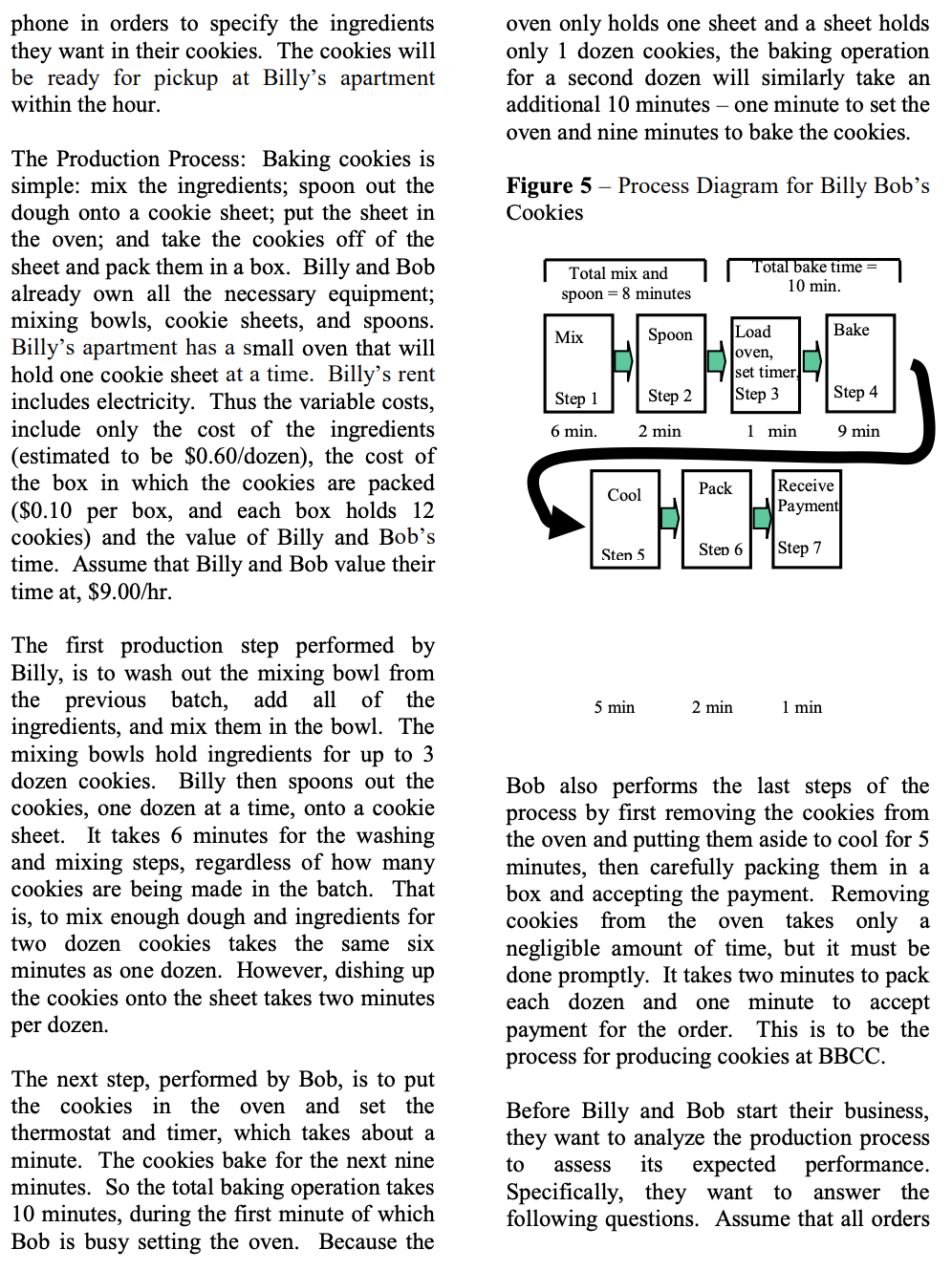

Process Analysis - Putting the Pieces Together: Billy Bob Cookies\" Billy and Bob are really excited about their new venture. Having discussed a cookie company case in their operations management class, Billy and Bob are planning to start their own company BillyBob Campus Cookies, BBCC. The idea is to provide fresh cookies to starving students late at night Cookies will be made to order, using any combination of ingredients the buyer wants, including chocolate chips, M&M's, chopped Heath bars, walnuts, raisins, ete. Buyers will phone in orders to specify the ingredients they want in their cookies. The cookies will be ready for pickup at Billy's apartment within the hour. The Production Process: Baking cookies is simple: mix the ingredients; spoon out the dough onto a cookie sheet; put the sheet in the oven; and take the cookies off of the sheet and pack them in a box. Billy and Bob already own all the necessary equipment; mixing bowls, cookie sheets, and spoons. Billy's apartment has a small oven that will hold one cookie sheet at a time. Billy's rent includes electricity. Thus the variable costs, include only the cost of the ingredients (estimated to be $0.60/dozen), the cost of the box in which the cookies are packed ($0.10 per box, and each box holds 12 cookies) and the value of Billy and Bob's time. Assume that Billy and Bob value their time at, $9.00/hr. The rst production step performed by Billy, is to wash out the mixing bowl from the previous batch, add all of the ingredients, and mix them in the bowl. The mixing bowls hold ingredients for up to 3 dozen cookies. Billy then spoons out the cookies, one dozen at a time, onto a cookie sheet. It takes 6 minutes for the washing and mixing steps, regardless of how many cookies are being made in the batch. That is, to mix enough dough and ingredients for two dozen cookies takes the same six minutes as one dozen. However, dishing up the cookies onto the sheet takes two minutes per dozen The next step, perfomred by Bob, is to put the cookies in the oven and set the thermostat and timer, which takes about a minute. The cookies bake for the next nine minutes. So the total baking operation takes 10 minutes, during the rst minute of which Bob is busy setting the oven. Because the oven only holds one sheet and a sheet holds only 1 dozen cookies, the baking operation for a second dozen will similarly take an additional 10 minutes one minute to set the oven and nine minutes to bake the cookies. Figure 5 Process Diagram for Billy Bob's Cookies I Totalrnixand I 0' .t1m= spoon = 8 minutes Mix Spoon Step 1 Ste-p 2 6min. 2min 5min 2min 1min Bob also performs the last steps of the process by rst removing the cookies from the oven and putting them aside to cool for 5 minutes, then carefully packing them in a box and accepting the payment. Removing cookies om the oven takes only a negligible amount of time, but it must be done promptly. It takes two minutes to pack each dozen and one minute to accept payment for the order. This is to be the process for producing cookies at BBCC. Before Billy and Bob start their business, they want to analyze the production process to assess its expected performance. Specically, they want to answer the following questions. Assume that all orders are for 1 dozen cookies and that BBCC gets enough orders to work without interrupting the production process

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts