Question: Production and distribution design. Microsys Corp is located in Seattle, Washington. The company has developed the WebSurfer, a low cost email and Web-surfing appliance. This

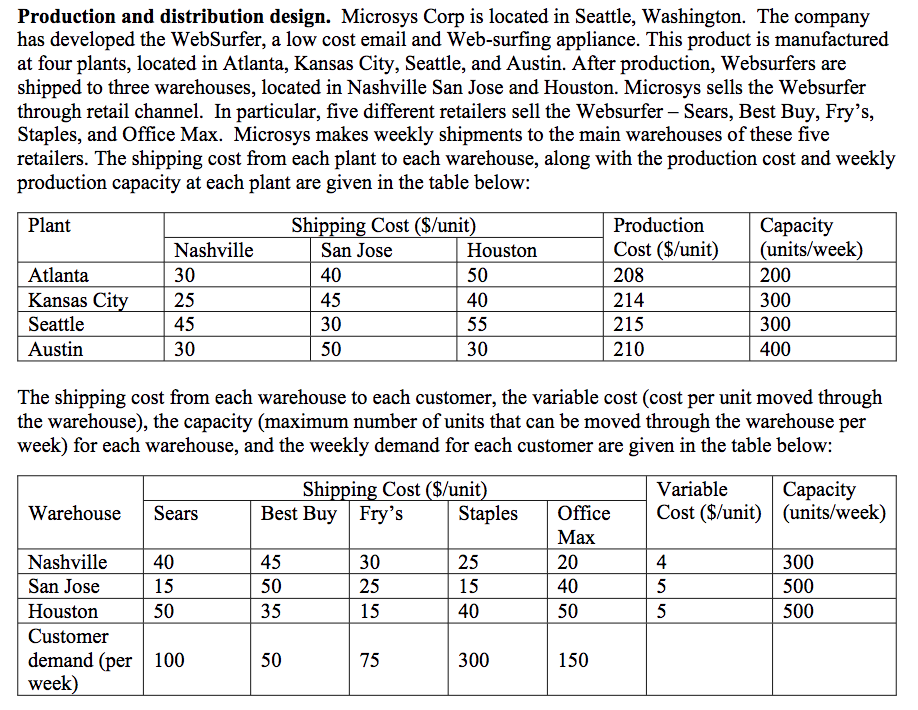

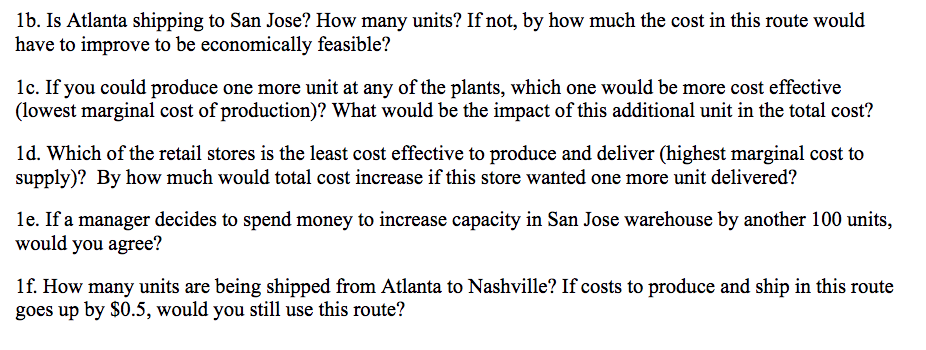

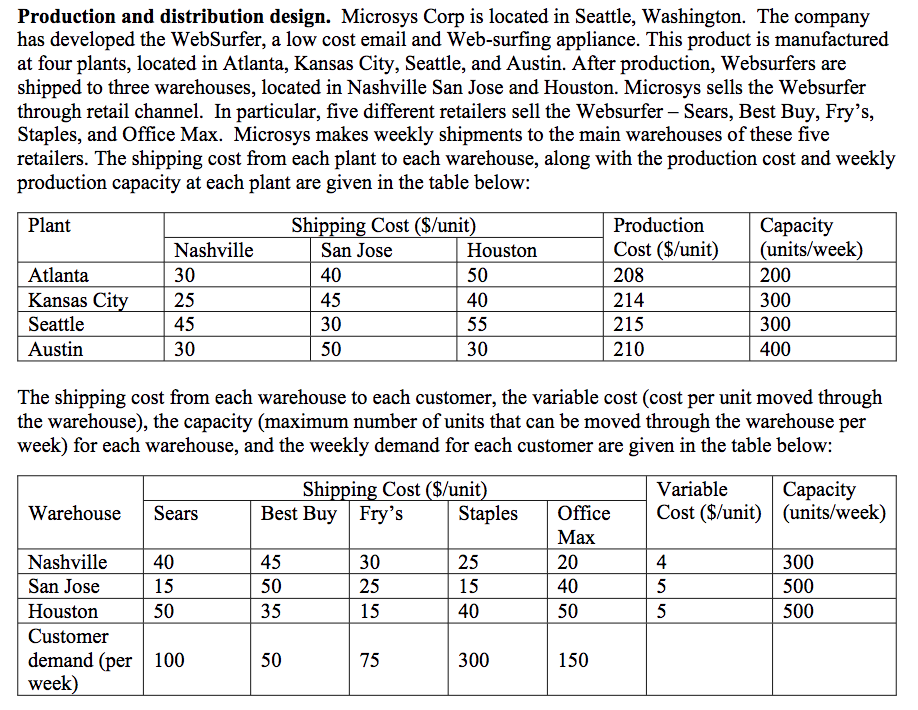

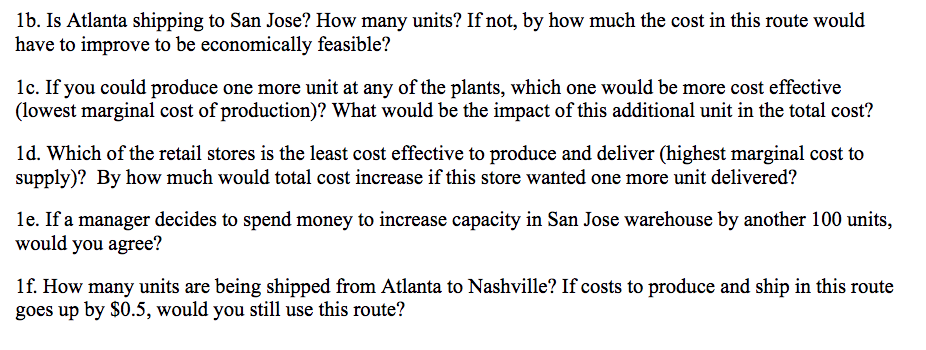

Production and distribution design. Microsys Corp is located in Seattle, Washington. The company has developed the WebSurfer, a low cost email and Web-surfing appliance. This product is manufactured at four plants, located in Atlanta, Kansas City, Seattle, and Austin. After production, Websurfers are shipped to three warehouses, located in Nashville San Jose and Houston. Microsys sells the Websurfer through retail channel. In particular, five different retailers sell the Websurfer - Sears, Best Buy, Fry's, Staples, and Office Max. Microsys makes weekly shipments to the main warehouses of these five retailers. The shipping cost from each plant to each warehouse, along with the production cost and weekly production capacity at each plant are given in the table below: Plant Nashville Shipping Cost ($/unit) San Jose Houston 40 50 45 40 30 Atlanta Kansas City Seattle Austin Production Cost ($/unit) 208 214 215 210 Capacity (units/week) 200 300 300 400 25 45 30 30 55 5 0 30 The shipping cost from each warehouse to each customer, the variable cost (cost per unit moved through the warehouse), the capacity (maximum number of units that can be moved through the warehouse per week) for each warehouse, and the weekly demand for each customer are given in the table below: Shipping Cost ($/unit) Best Buy Fry's Staples Variable Cost ($/unit) Capacity (units/week) Warehouse Sears Office Max 20 405 45 30 4 50 35 25 15 25 15 40 300 500 | 500 50 Nashville San Jose 15 Houston Customer demand (per 100 week) 50 300 150 1b. Is Atlanta shipping to San Jose? How many units? If not, by how much the cost in this route would have to improve to be economically feasible? 1c. If you could produce one more unit at any of the plants, which one would be more cost effective (lowest marginal cost of production)? What would be the impact of this additional unit in the total cost? 1d. Which of the retail stores is the least cost effective to produce and deliver (highest marginal cost to supply)? By how much would total cost increase if this store wanted one more unit delivered? le. If a manager decides to spend money to increase capacity in San Jose warehouse by another 100 units, would you agree? 1f. How many units are being shipped from Atlanta to Nashville? If costs to produce and ship in this route goes up by $0.5, would you still use this route