Question: Production and Inventory Planning Problem Under normal working conditions, a factory produces up to 100 units of high-power flashlights in each of four consecutive time

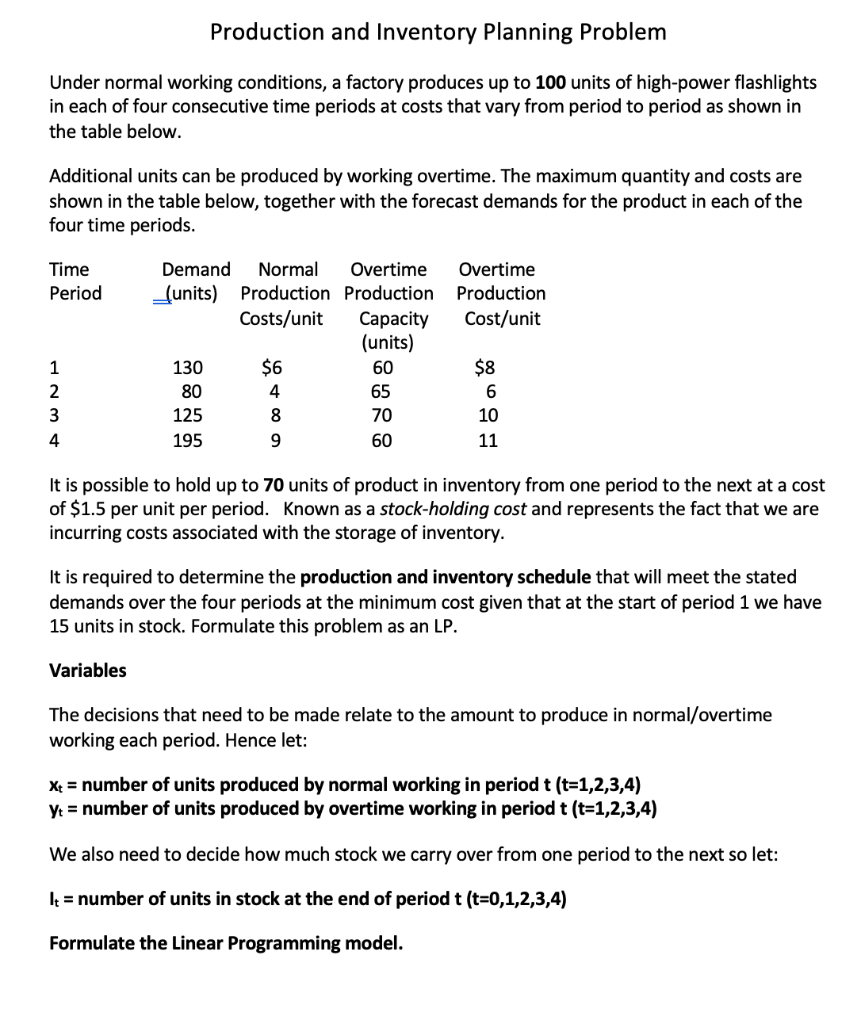

Production and Inventory Planning Problem Under normal working conditions, a factory produces up to 100 units of high-power flashlights in each of four consecutive time periods at costs that vary from period to period as shown in the table below. Additional units can be produced by working overtime. The maximum quantity and costs are shown in the table below, together with the forecast demands for the product in each of the four time periods. It is possible to hold up to 70 units of product in inventory from one period to the next at a cost of \$1.5 per unit per period. Known as a stock-holding cost and represents the fact that we are incurring costs associated with the storage of inventory. It is required to determine the production and inventory schedule that will meet the stated demands over the four periods at the minimum cost given that at the start of period 1 we have 15 units in stock. Formulate this problem as an LP. Variables The decisions that need to be made relate to the amount to produce in normal/overtime working each period. Hence let: xt= number of units produced by normal working in period t(t=1,2,3,4) yt= number of units produced by overtime working in period t(t=1,2,3,4) We also need to decide how much stock we carry over from one period to the next so let: It= number of units in stock at the end of period t(t=0,1,2,3,4) Formulate the Linear Programming model

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts