Question: Production Linear Programming problem. My dog Molly runs a biscuit manufacturing plant. The demand, production cost, holding cost, and production capacity vary from month to

Production Linear Programming problem.

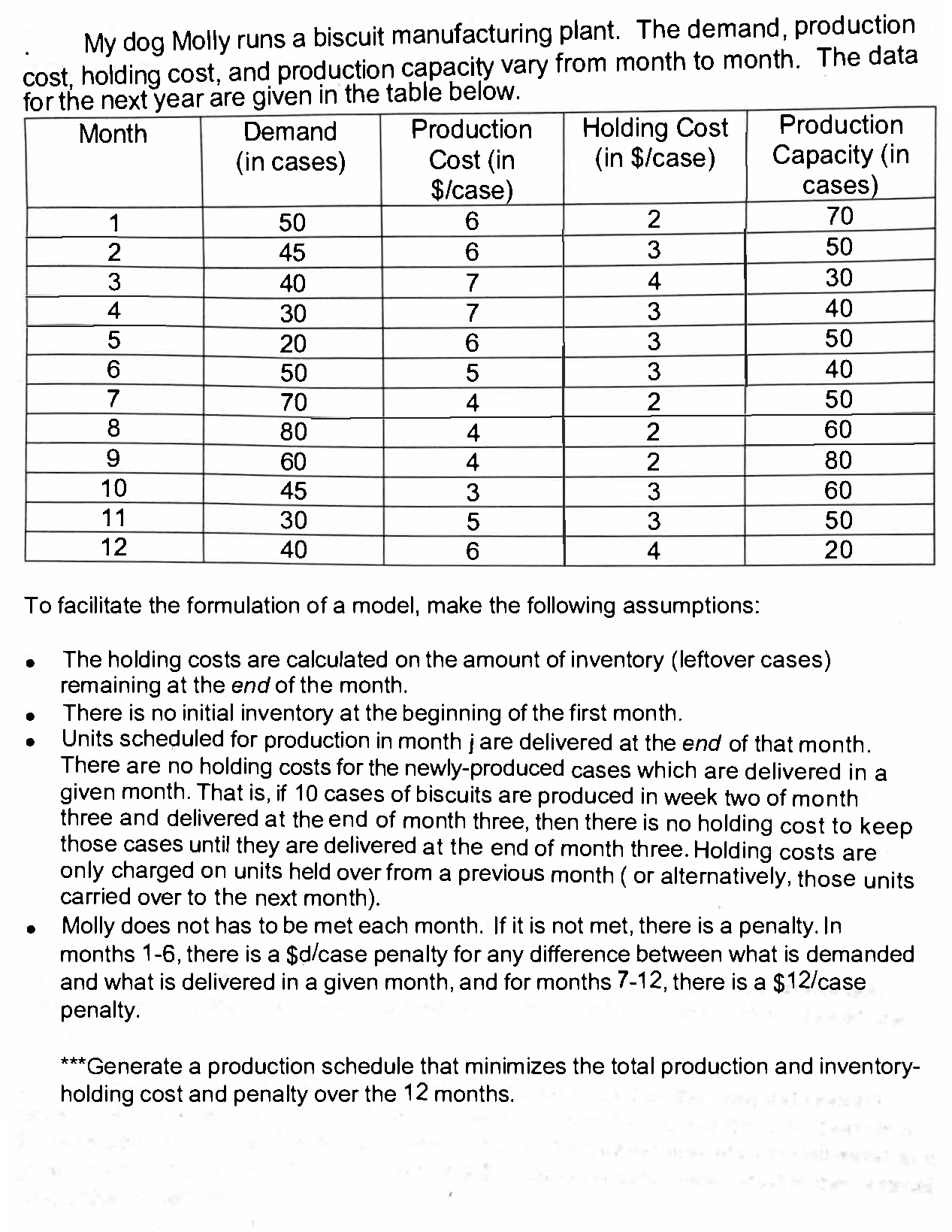

My dog Molly runs a biscuit manufacturing plant. The demand, production cost, holding cost, and production capacity vary from month to month. The data for the next year are given in the table below. To facilitate the formulation of a model, make the following assumptions: The holding costs are calculated on the amount of inventory (leftover cases) remaining at the end of the month. There is no initial inventory at the beginning of the first month. Units scheduled for production in month j are delivered at the end of that month. There are no holding costs for the newly-produced cases which are delivered in a given month. That is, if 10 cases of biscuits are produced in week two of month three and delivered at the end of month three, then there is no holding cost to keep those cases until they are delivered at the end of month three. Holding costs are only charged on units held over from a previous month ( or alternatively, those units carried over to the next month). Molly does not has to be met each month. If it is not met, there is a penalty. In months 1-6, there is a $d/case penalty for any difference between what is demanded and what is delivered in a given month, and for months 7-12, there is a $12/case penalty. ***Generate a production schedule that minimizes the total production and inventory-holding cost and penalty over the 12 months

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts