Question: Proposed problem: A bending machine was given with working speed of 10r/min (high speed) and 5r/min (low speed), power motor 3kw-4P and input voltage 380V.

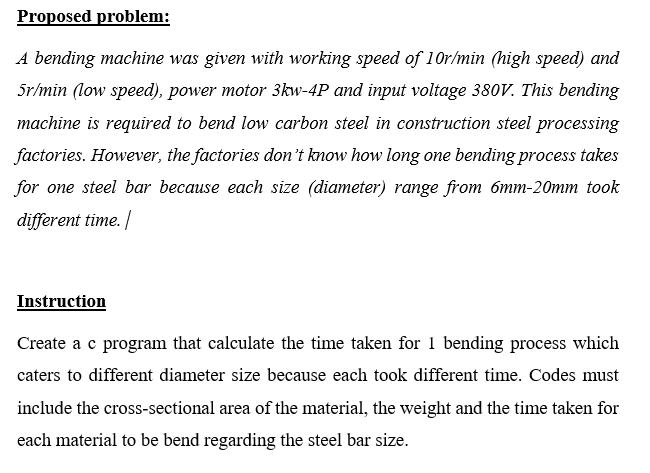

Proposed problem: A bending machine was given with working speed of 10r/min (high speed) and 5r/min (low speed), power motor 3kw-4P and input voltage 380V. This bending machine is required to bend low carbon steel in construction steel processing factories. However, the factories don't know how long one bending process takes for one steel bar because each size (diameter) range from 6mm-20mm took different time./ Instruction Create a c program that calculate the time taken for 1 bending process which caters to different diameter size because each took different time. Codes must include the cross-sectional area of the material, the weight and the time taken for each material to be bend regarding the steel bar size. Proposed problem: A bending machine was given with working speed of 10r/min (high speed) and 5r/min (low speed), power motor 3kw-4P and input voltage 380V. This bending machine is required to bend low carbon steel in construction steel processing factories. However, the factories don't know how long one bending process takes for one steel bar because each size (diameter) range from 6mm-20mm took different time./ Instruction Create a c program that calculate the time taken for 1 bending process which caters to different diameter size because each took different time. Codes must include the cross-sectional area of the material, the weight and the time taken for each material to be bend regarding the steel bar size

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts