Question: Q 1 . A mini - MP 3 player manufacturing company has to manufacture two different models of its products, A 1 0 1 and

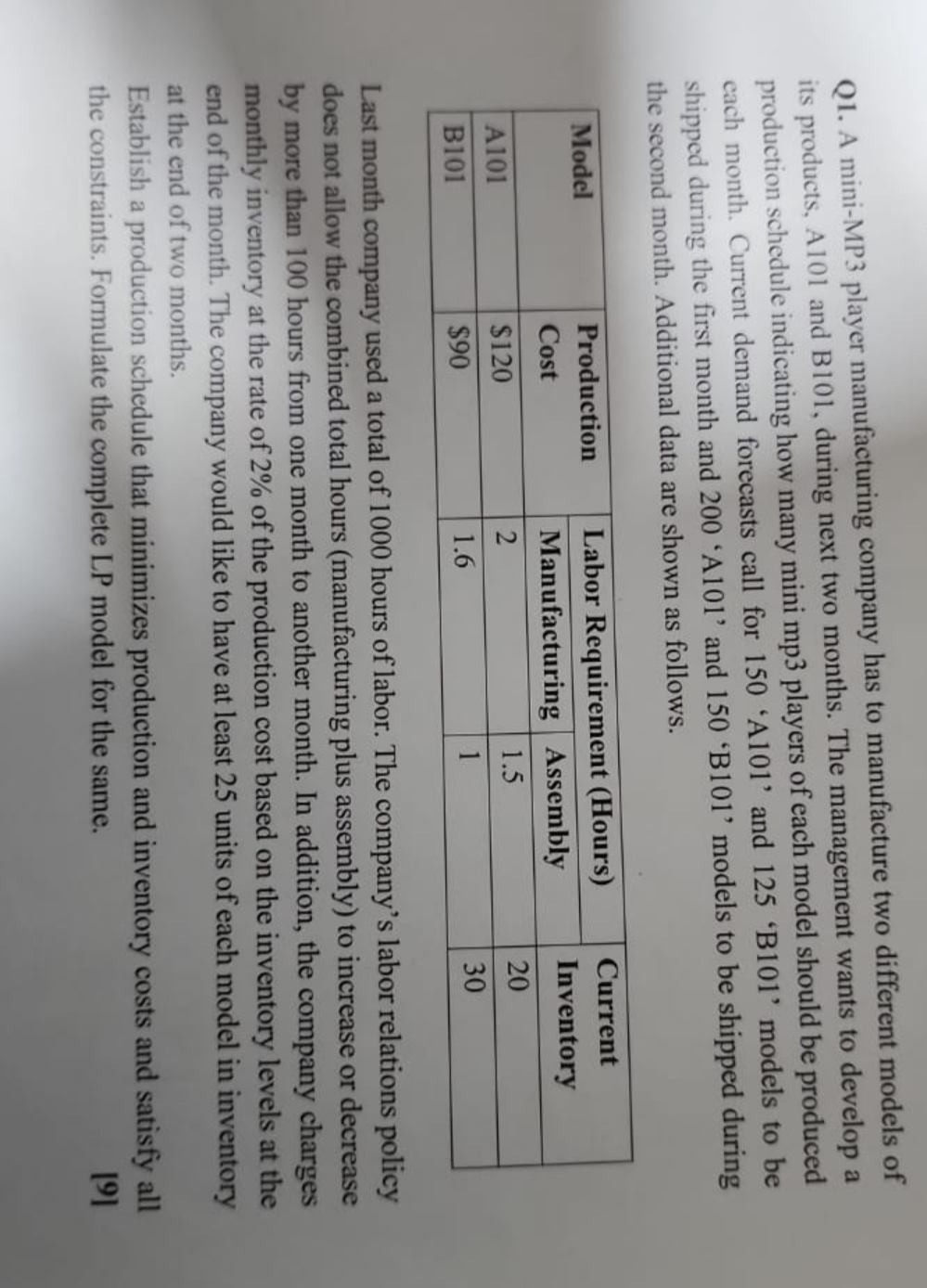

Q A miniMP player manufacturing company has to manufacture two different models of its products, A and B during next two months. The management wants to develop a production schedule indicating how many mini players of each model should be produced each month. Current demand forecasts call for A and B models to be shipped during the first month and A and B models to be shipped during the second month. Additional data are shown as follows.

tableModeltableProductionCostLabor Requirement HourstableCurrentInventoryAssemblyA$B$

Last month company used a total of hours of labor. The company's labor relations policy does not allow the combined total hours manufacturing plus assembly to increase or decrease by more than hours from one month to another month. In addition, the company charges monthly inventory at the rate of of the production cost based on the inventory levels at the end of the month. The company would like to have at least units of each model in inventory at the end of two months.

Establish a production schedule that minimizes production and inventory costs and satisfy all the constraints. Formulate the complete LP model for the same.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock