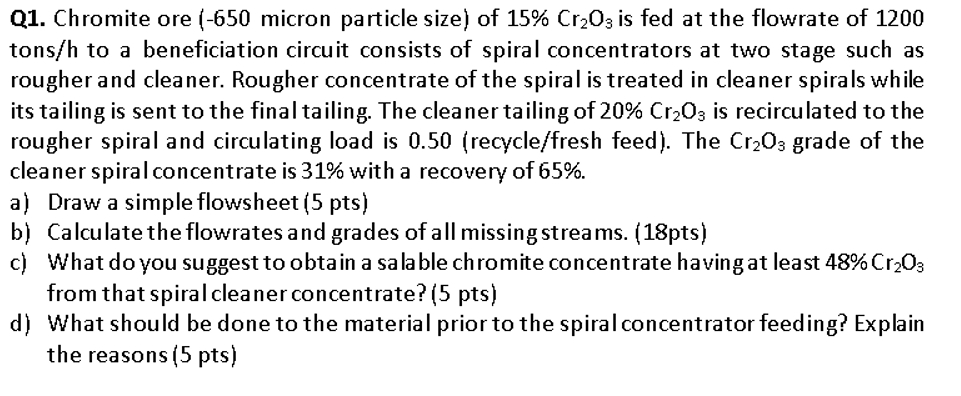

Question: Q 1 . Chromite ore ( - 6 5 0 micron particle size ) of 1 5 % C r 2 O 3 is fed

Q Chromite ore micron particle size of is fed at the flowrate of

tonsh to a beneficiation circuit consists of spiral concentrators at two stage such as

rougher and cleaner. Rougher concentrate of the spiral is treated in cleaner spirals while

its tailing is sent to the final tailing. The cleaner tailing of is recirculated to the

rougher spiral and circulating load is recyclefresh feed The grade of the

cleaner spiral concentrate is with a recovery of

a Draw a simple flowsheet pts

b Calculate the flowrates and grades of all missing streams. pts

c What do you suggest to obta in a sa lable chromite concentrate having at least

from that spiral cleaner concentrate? pts

d What should be done to the material prior to the spiral concentrator feeding? Explain

the reasons pts

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock