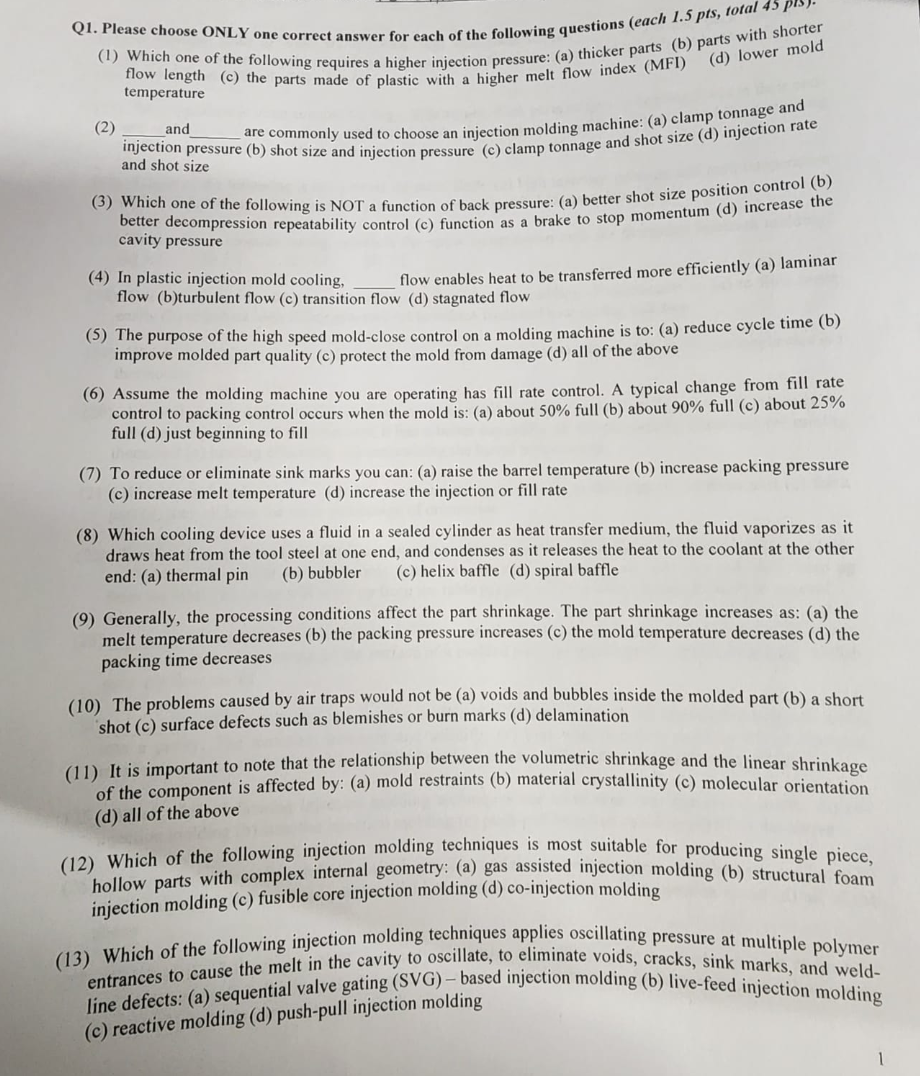

Question: Q 1 . Please choose ONLY one correct answer for each of the following questions ( each 1 . 5 p t s , total

Q Please choose ONLY one correct answer for each of the following questions each total

Which one of the following requires a higher injection pressure: a thicker parts b parts with shorter flow length c the parts made of plastic with a higher melt flow index MFI

d lower mold temperature

anc are commonly used to choose an injection molding machine: a clamp tonnage and injection pressure b shot size and injection pressure c clamp tonnage and shot size d injection rate and shot size

Which one of the following is NOT a function of back pressure: a better shot size position control b better decompression repeatability control c function as a brake to stop momentum d increase the cavity pressure

In plastic injection mold cooling, flow enables heat to be transferred more efficiently a laminar flow

bturbulent flow

c transition flow d stagnated flow

The purpose of the high speed moldclose control on a molding machine is to: a reduce cycle time b improve molded part quality c protect the mold from damage d all of the above

Assume the molding machine you are operating has fill rate control. A typical change from fill rate control to packing control occurs when the mold is: a about full b about full c about full d just beginning to fill

To reduce or eliminate sink marks you can: a raise the barrel temperature b increase packing pressure c increase melt temperature

d increase the injection or fill rate

Which cooling device uses a fluid in a sealed cylinder as heat transfer medium, the fluid vaporizes as it draws heat from the tool steel at one end, and condenses as it releases the heat to the coolant at the other end: a thermal pin

b bubbler

c helix baffle

d spiral baffle

Generally, the processing conditions affect the part shrinkage. The part shrinkage increases as: a the melt temperature decreases b the packing pressure increases c the mold temperature decreases d the packing time decreases

The problems caused by air traps would not be a voids and bubbles inside the molded part b a short shot c surface defects such as blemishes or burn marks d delamination

It is important to note that the relationship between the volumetric shrinkage and the linear shrinkage of the component is affected by: a mold restraints b material crystallinity c molecular orientation d all of the above

Which of the following injection molding techniques is most suitable for producing single piece, hollow parts with complex internal geometry: a gas assisted injection molding b structural foam injection molding c fusible core injection molding d coinjection molding

Which of the following injection molding techniques applies oscillating pressure at multiple polymer entrances to cause the melt in the cavity to oscillate, to eliminate voids, cracks, sink marks, and weldline defects: a sequential valve gating SVG based injection molding b livefeed injection molding

c reactive molding d pushpull injection molding

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock