Question: Q . 2 . A distillation column is to be designed to separate a mixture of acetone water having a maximum feed rate of 1

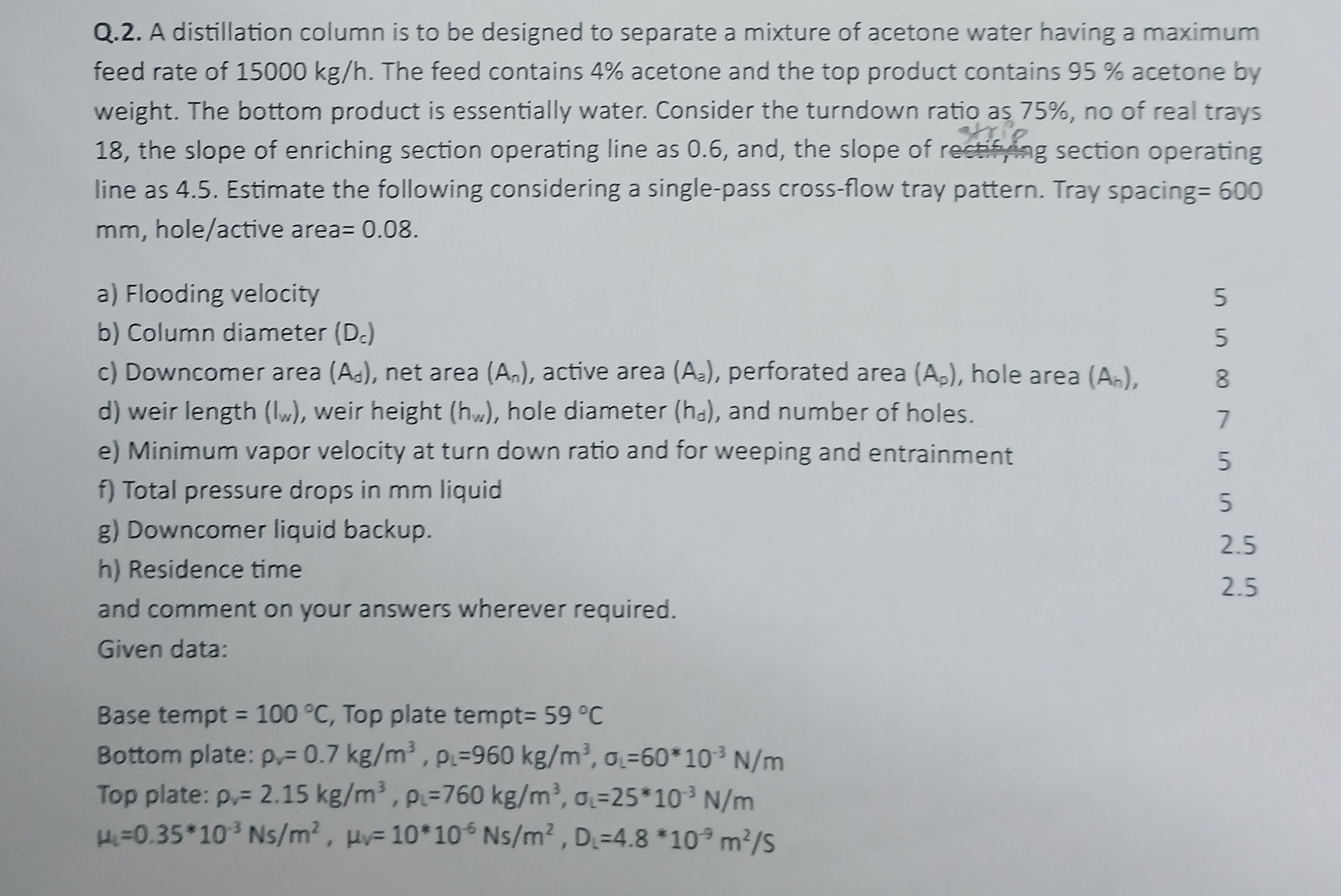

Q A distillation column is to be designed to separate a mixture of acetone water having a maximum

feed rate of The feed contains acetone and the top product contains acetone by

weight. The bottom product is essentially water. Consider the turndown ratio as no of real trays

the slope of enriching section operating line as and, the slope of rectifing section operating

line as Estimate the following considering a singlepass crossflow tray pattern. Tray spacing

holeactive area

a Flooding velocity

b Column diameter :

c Downcomer area net area active area perforated area hole area

d weir length : weir height hole diameter and number of holes.

e Minimum vapor velocity at turn down ratio and for weeping and entrainment

f Total pressure drops in mm liquid

g Downcomer liquid backup.

h Residence time

and comment on your answers wherever required.

Given data:

Base tempt Top plate tempt

Bottom plate:

Top plate:

A column is to be designed to separate a mixture of ethylbenzene and styrene. The feed will contain mol fraction styrene, and a styrene purity of is required, with a recovery of Estimate the number of equilibrium stages required at a reflux ratio of Maximum column bottom pressure bar. FormulaExpressions: ud 'OOL

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock